System for removing paraffin blockage of oil pipe

A technology for removing systems and oil pipes, which is applied to cleaning appliances, wellbore/well components, isolation devices, etc., can solve problems such as unsatisfactory practical application, poor wax dissolution effect, and large loss, achieving low cost, high solution cost, The effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

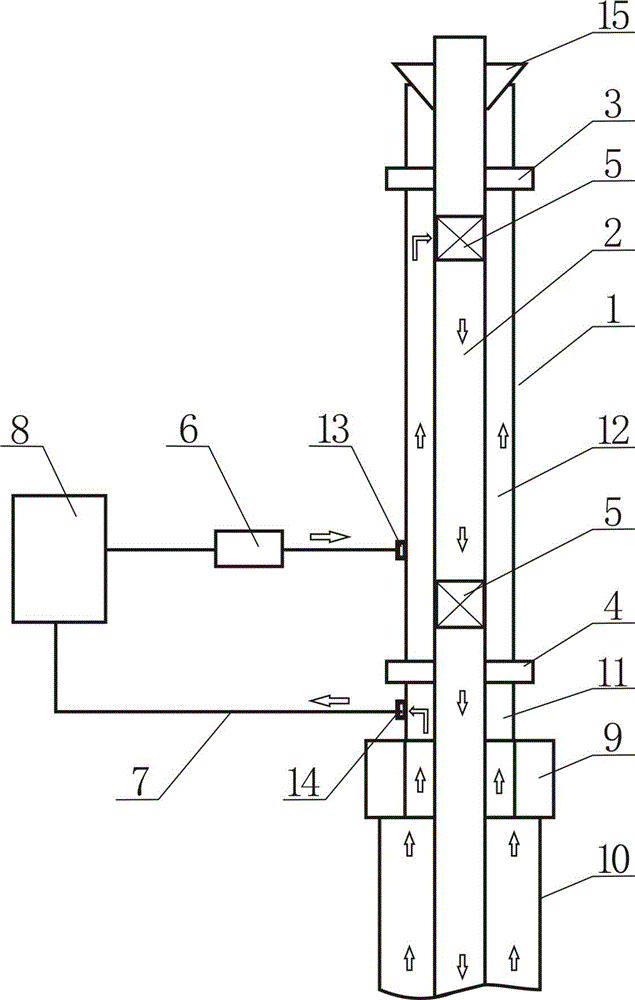

[0019] Such as figure 1 As shown, the tubing wax plug removal system is mainly composed of an outer pipe 1, a well flushing pipe 2, an upper seal 3, a lower seal 4, a self-switching tee 5, a pump 6, a cleaning fluid pipeline 7 and a heater 8. The lower end of the outer pipe 1 is fixed on the wellhead christmas tree 9 and communicates with the production tubing 10 at the bottom of the wellhead christmas tree 9, and the lower end of the well cleaning pipe 2 passes through the outer pipe 1 and the wellhead christmas tree 9 in turn, and extends into the In the production tubing 10, the upper seal 3 and the lower seal 4 are distributed at intervals along the axial direction of the outer pipe 1, separating the annulus 11 between the outer pipe 1 and the well cleaning pipe 2 into a closed annulus section 12. The switching tee 5 is arranged on the well flushing pipe 2 and is located in the closed annular space section 12. The pipe wall of the outer pipe 1 is provided with a liquid inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com