Material erosion testing machine

A technology of testing machine and sand material, which is applied in the direction of testing wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

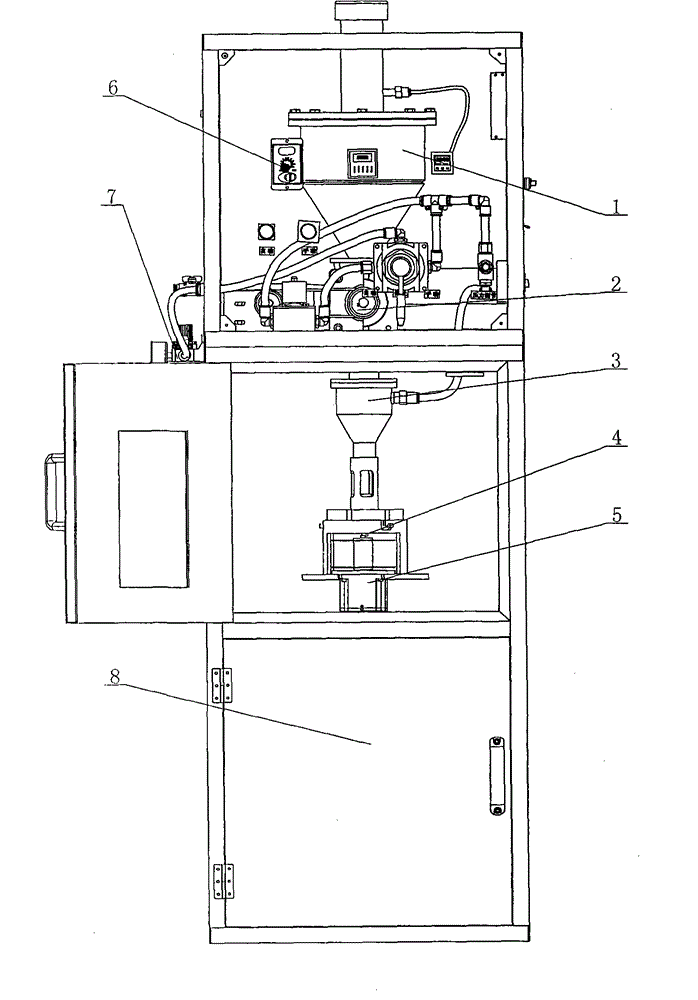

[0007] There is a grid plate platform in the testing machine housing, a feeder 2 is arranged on the grid plate platform, and a sand bin 1 is arranged on the upper part of the feeder, and the sand bin communicates with the feeder. There is a sand material controller 6 on the sand material bin. There is a wind control device 7 outside the testing machine housing. There is a gas material mixing tank 3 at the bottom of the feeder. The air control device communicates with the sand silo and the gas material mixing tank through connecting pipes. There is a nozzle 4 on the lower outlet of the gas material mixing tank. There is a speedometer 5 below the gas-material mixing tank. There is a dust collecting chamber 8 at the bottom of the body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com