Non-contact solid burning rate testing method

A solid combustion rate and testing method technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of affecting the measurement accuracy, affecting the shape of the sample, and reducing the accuracy, so as to achieve high temperature resolution and improve The effect of measurement accuracy and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

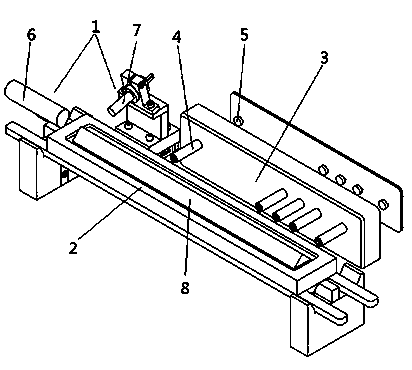

[0020] Such as figure 1 As shown, taking an infrared pyroelectric sensor as a photosensitive sensor as an example, a detailed implementation and a specific operation process are given, but the scope of protection of the present invention is not limited to the following examples.

[0021] (1) Place the sample 8 in the shape of a strip or powder strip on the sample setter 2 that is impermeable, non-combustible, and low in thermal conductivity according to the test requirements. If the substance to be tested is powder or granular, use a stacking mold to make a powder tape; if the substance to be tested is solid, directly take a continuous and complete strip as the sample.

[0022] (2) Use a suitable ignition device 1 to heat one end of the sample until the sample is ignited. Ignition device 1 includes gas igniter 6 and solid igniter 7. If the substance to be tested is in pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com