Method for manufacturing wound type thin-film capacitor

A technology of film capacitors and production methods, which can be applied to film/thick film capacitors, wire wound capacitors, multilayer capacitors, etc., and can solve problems such as cracks in the center of wound capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

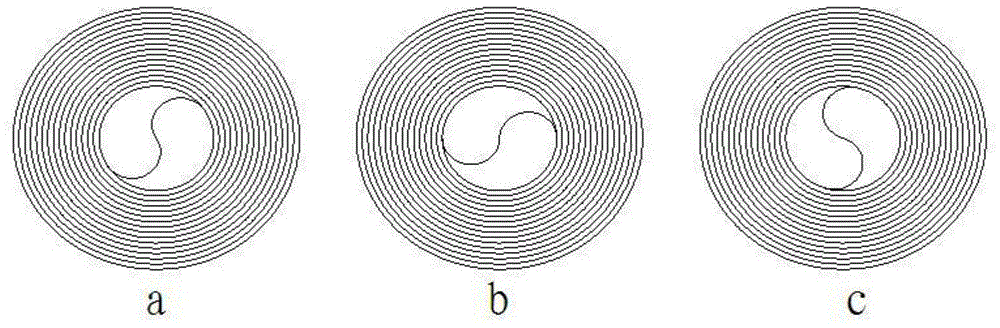

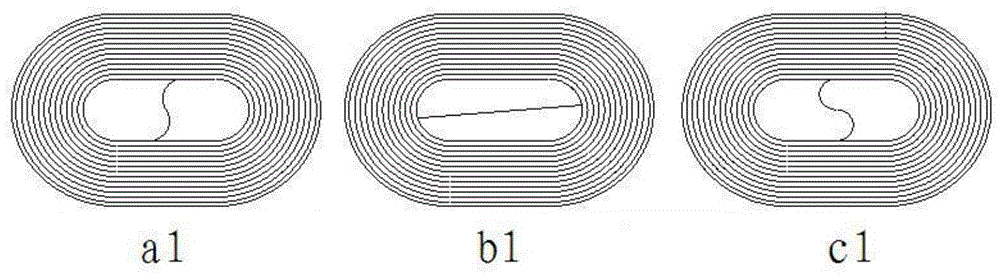

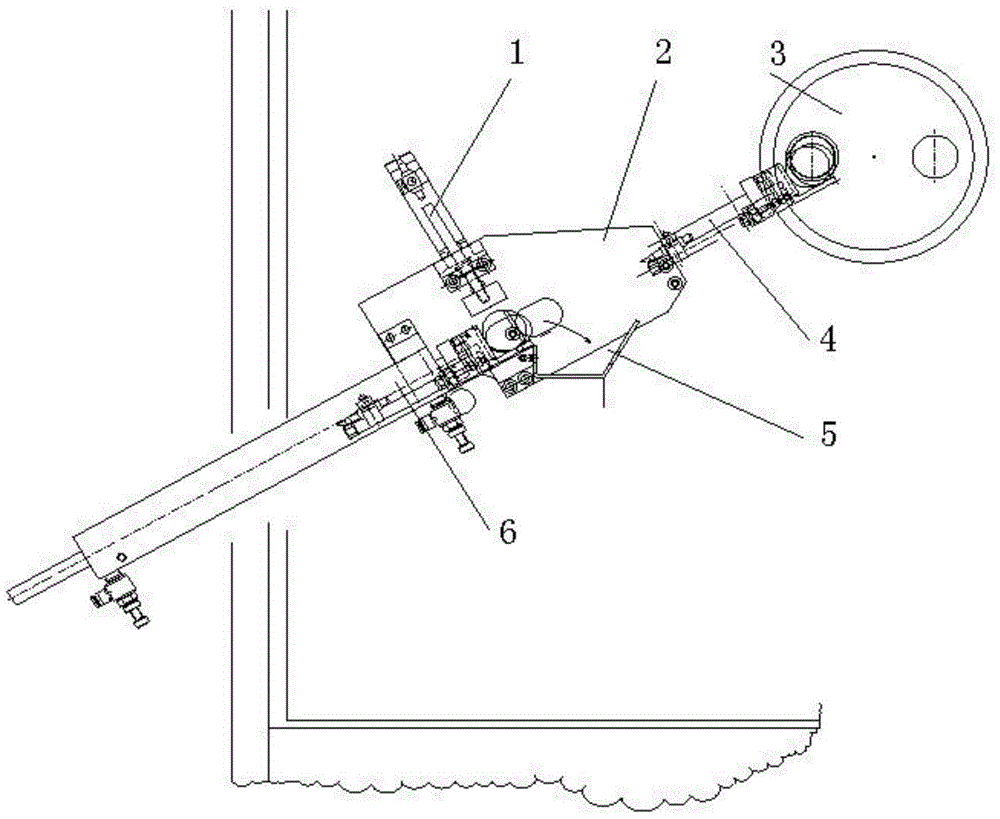

[0016] A method for manufacturing a winding type film capacitor, comprising the following steps: winding process: placing the capacitor raw material on a capacitor winding machine 3 and winding it into a circular capacitor core with a winding core in the middle, preferably, the capacitor raw material It is a metallized organic film, or metal foil and plastic film; pre-stamping process: the circular capacitor core formed in the winding process is placed on a pre-stamping device, and the pre-stamping device then presses the circle Two parallel end faces are extruded from the circumferential surface of the shaped capacitor core, so that the circular capacitor core is pre-pressed into a flat capacitor core that is not ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com