Steel tube tower maintenance operation platform and using method thereof

A technology of working platforms and steel pipe towers, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as inability to carry out operations, large distances between structural parts, etc., and achieve the effect of ensuring safety and meeting the needs of operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The utility model relates to an inspection operation platform for 1000kV UHV steel pipe tower, which is suitable for steel pipe tower lines and provides an operation platform for personnel inspection and maintenance operations.

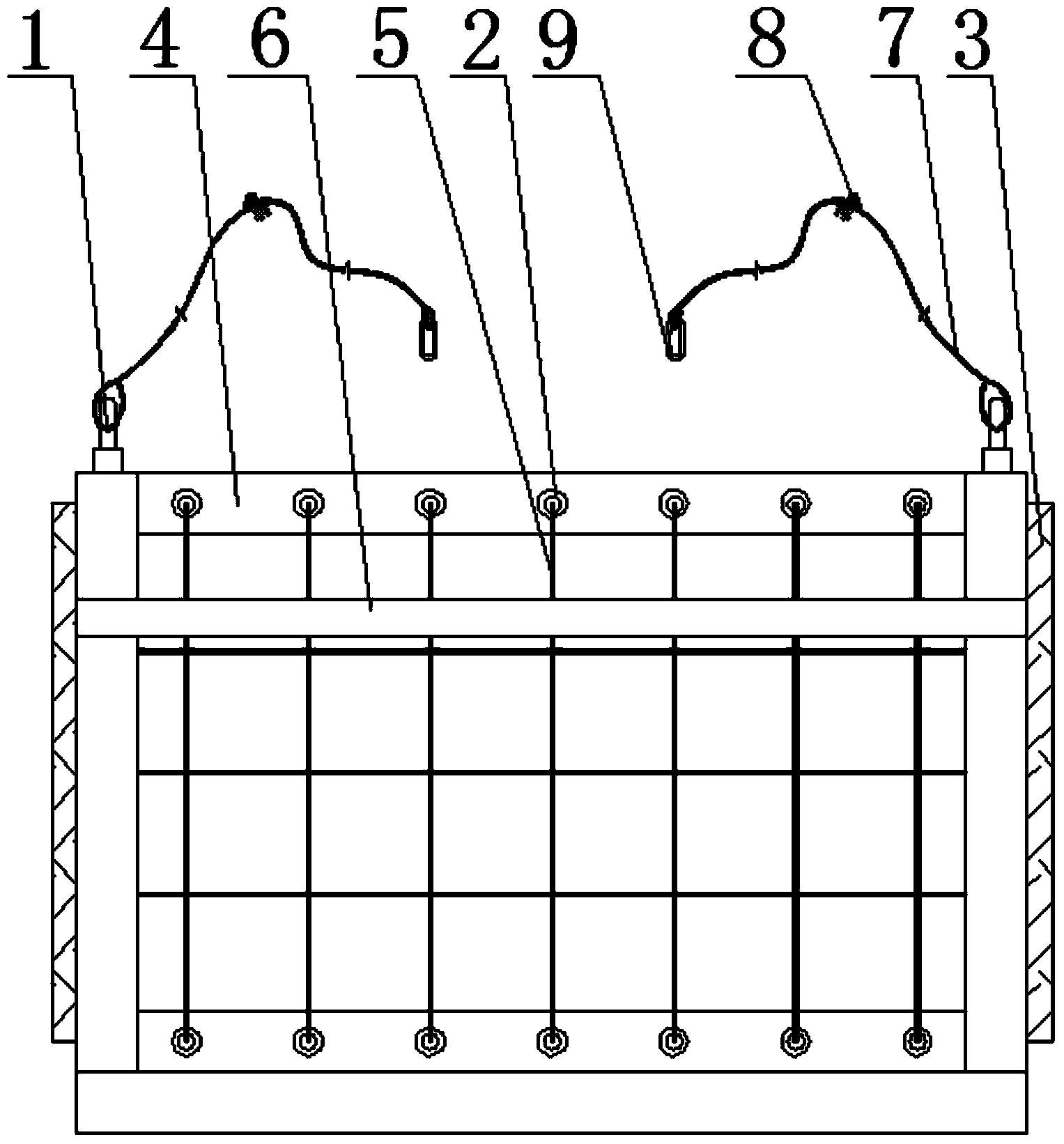

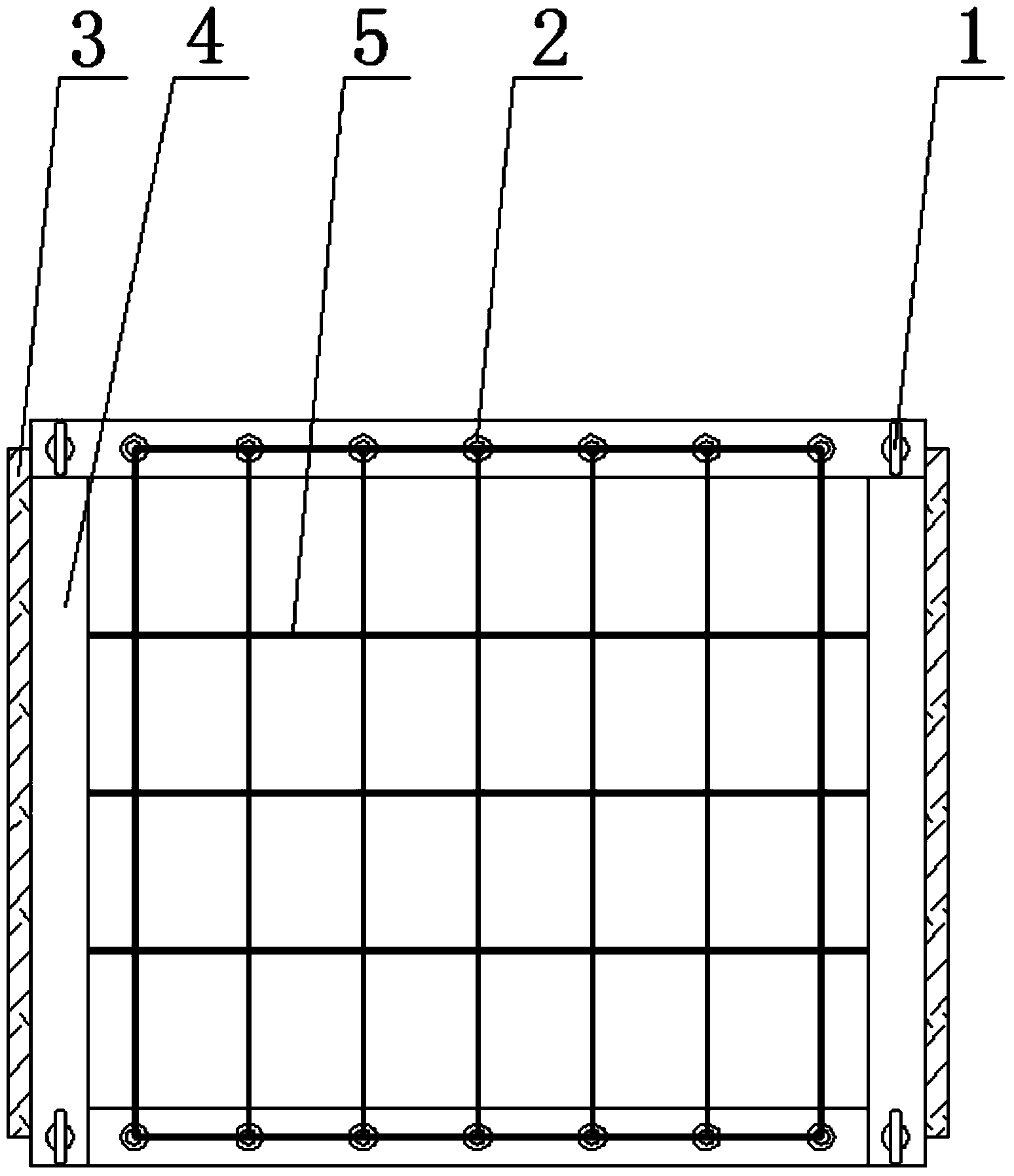

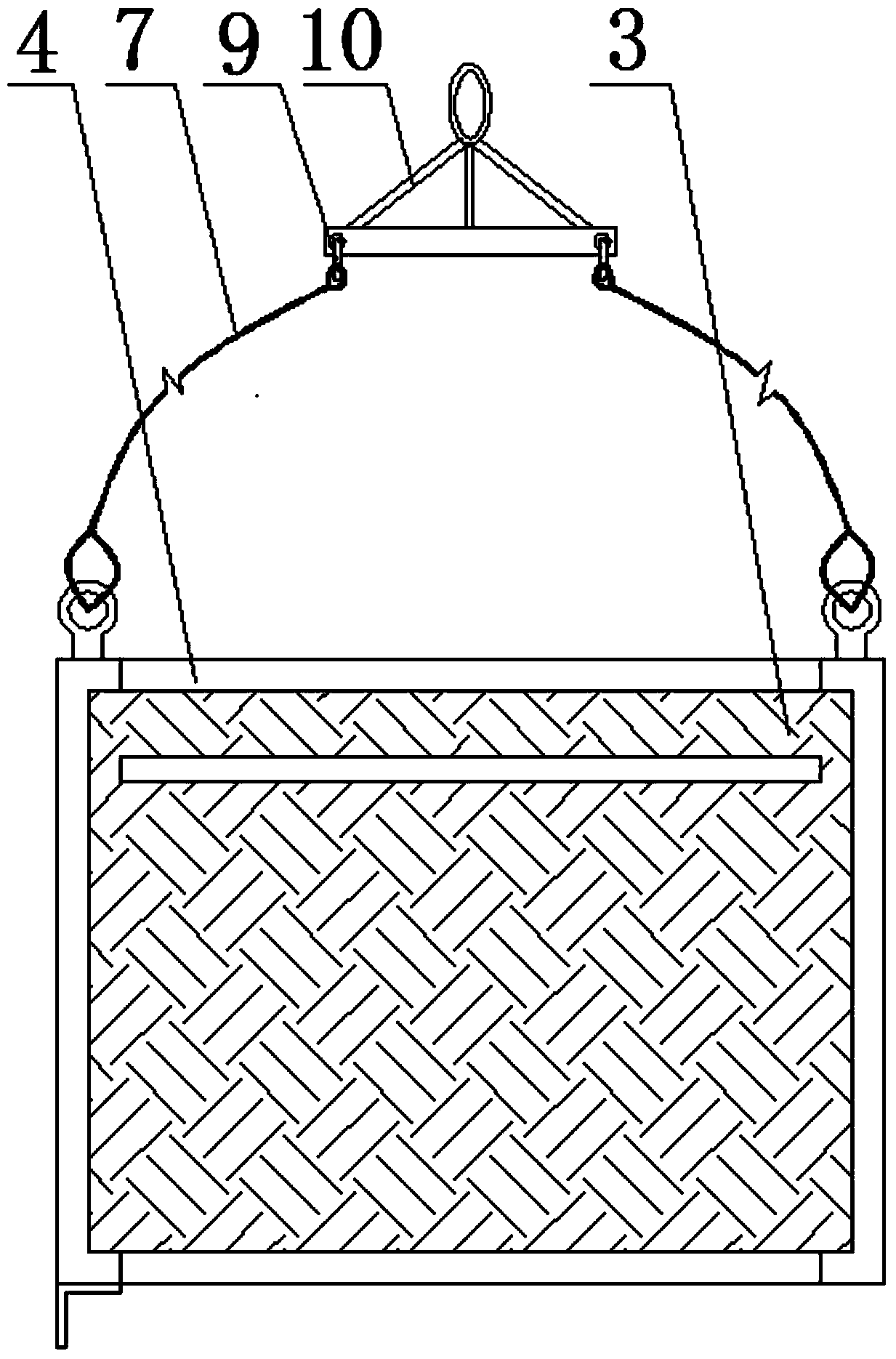

[0024] Such as figure 1 As shown, the main body of the work platform is a square frame 4 made of aluminum alloy profiles. Connection holes for installing rope nets are provided on the bottom, side and rear frames of the square frame, and each connection hole is lined with a useful In order to prevent the anti-friction washer 2 of rope wear and tear, the insulating rope net 5 that nylon is made is contained in the bottom surface, the side and the back of square frame 4 respectively. And be provided with the tool bag 3 that canvas is made outside the both sides of square frame 4, in the front of square frame 4 fixedly install a soft waist rope 6, the waist rope can be opened and buckled on the front frame, in square frame 4 The tops of the four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com