A preheating process of dust collector for filtering combustible dust-laden gas

A dust collector and process technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of difficult to guarantee the safety performance of combustible components, low preheating temperature, and difficult to apply, so as to improve the safety performance of equipment , Small footprint, reasonable layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

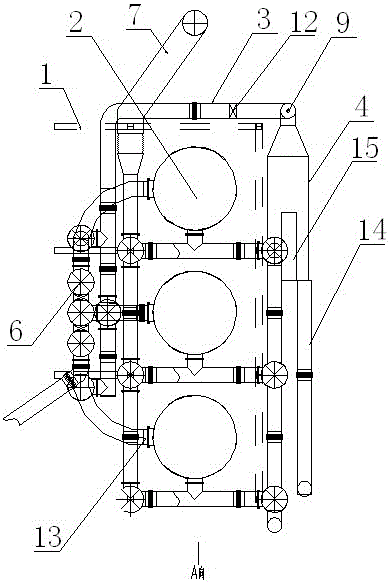

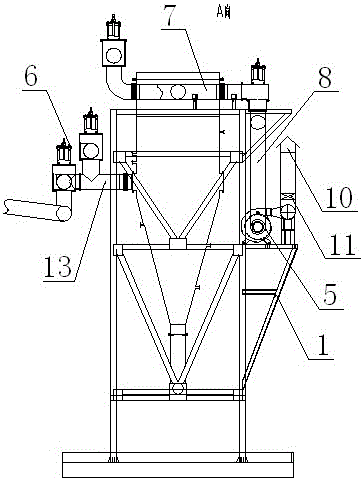

[0023] A dust collector preheating process for filtering combustible dust-laden gas, involving equipment including a hot blast pipe 3 arranged on the side of the dust collector 2 through a support frame 1, and a hot blast stove 4 and a fan 5 are connected in series to the hot blast pipe 3 , the fan 5 is arranged at the front section of the air intake of the hot blast stove 4, and the air outlet of the clean air chamber of the dust collector 2 is connected to the clean air delivery pipeline 7 of the dust collector 2, and the clean air delivery pipeline 7 is located at a high position, and the The clean gas conveying pipeline 7 is provided with the branch air pipe 8 connecting the blower fan 5, the output end of the hot blast stove 4 is provided with a chimney 9, and an emptying mechanism 10, temperature Detection device and oxygen content detection device, described emptying mechanism 10 and chimney 9 are provided with electric regulating valve 11, and described emptying mechani...

Embodiment 2

[0026]The difference from Embodiment 1 is that: the hot air duct 3 is provided with several groups of output end branches, which can be one group, two groups, four groups, or even more, and the several groups of output end branches are respectively connected to parallel dust collectors 2 The dusty gas intake pipe 13.

Embodiment 3

[0028] The difference from Embodiment 1 or 2 is that: the heating temperature in the heating stage is 330°C, and the replacement adjustment stage makes the oxygen content in the dust collector 2 after adjustment be 1.4%, wherein the temperature rising rate in the heating stage is controlled to be <100°C / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com