Sheet cold extruding forming method for wide-flange conical part

A cold extrusion and flange technology, applied in the field of extrusion forming, can solve problems such as low yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

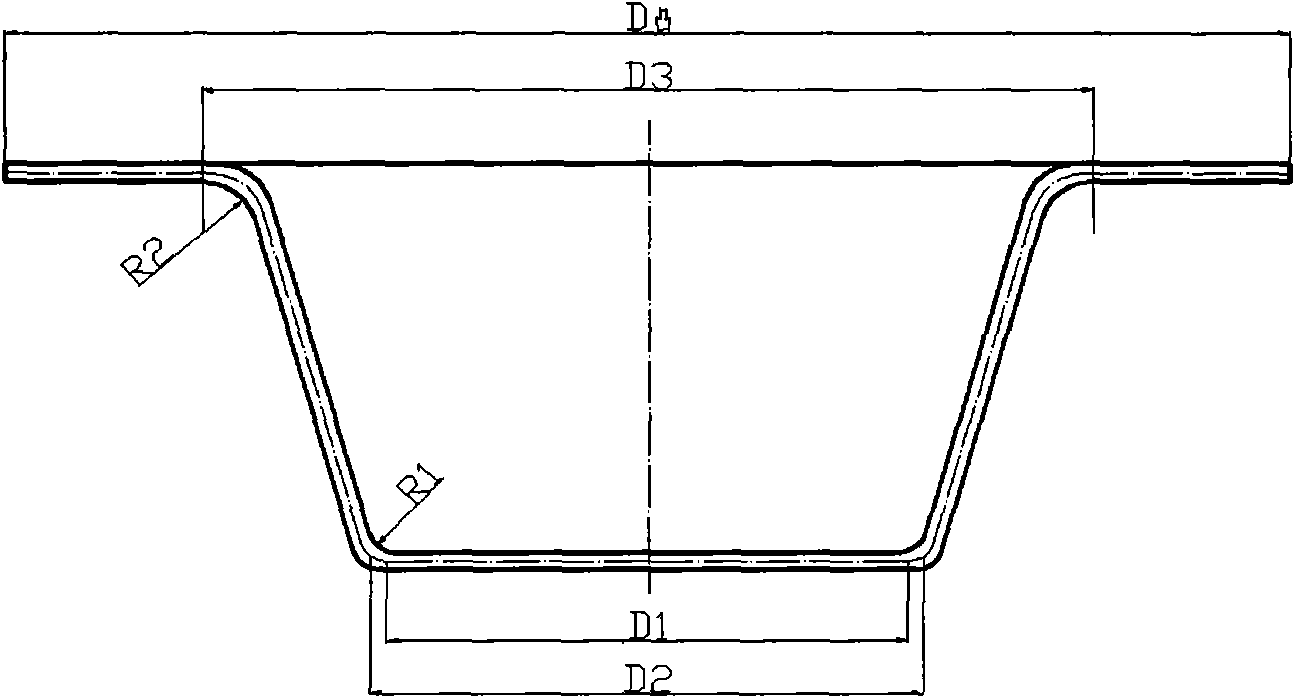

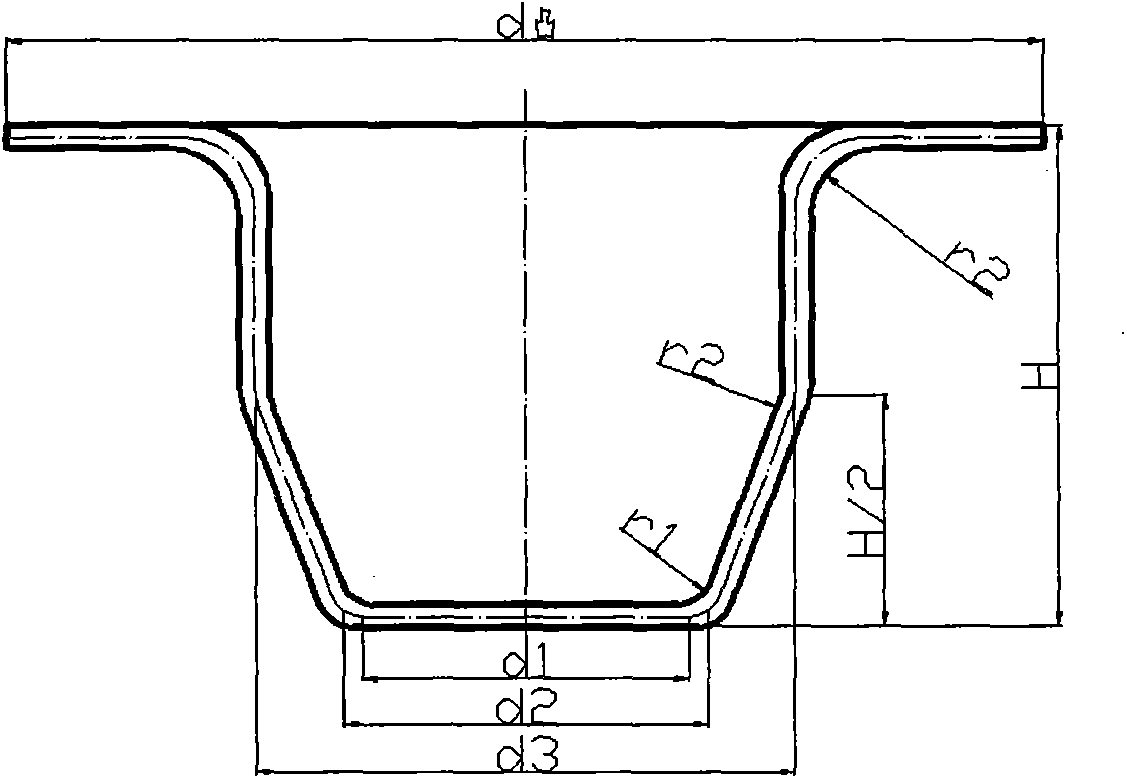

[0019] Taking the processing of a wide flange conical product as an example, its structure is as follows figure 1 As shown, the specific size parameters are: t=5, D 凸 =250,R 1 =15,R 2 =25.

[0020] Adopt thin plate cold extrusion forming method of the present invention, concrete steps are as follows:

[0021] Step 1), determine trimming allowance; d 凸 =240,d 凸 / d=1.09, find out that δ=5.5, get d after correction 凸 =240+2×5.5=262.

[0022] Step 2), initial calculation blank diameter D; find out the formula D=(d 4 2 +4d 2 H-3.44rd 2 ) 1 / 2 . r=40, d 2 =170, d 4 =262, H=146, and D=380 after substitution.

[0023] Step 3), determine the drawing coefficient m during the first drawing 1 ; because d 凸 / d1 =0.59.

[0024] Step 4), determine the drawing coefficient and the number of times of drawing during the rest of the drawing, and calculate the diameter of each drawing; look up the table to obtain m 2 =0.88, m ,3 =0.88,m 4 =0.88, m 5 = 0.88. d 1 =1.07×0.59×38...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com