Measuring device and die core processing method using same

A measuring device and a mold core processing technology, applied in metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc., can solve problems such as damage, laser processing machine crashes, laser processor falling height and impact on mold cores, etc. , to achieve the effect of ensuring the machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

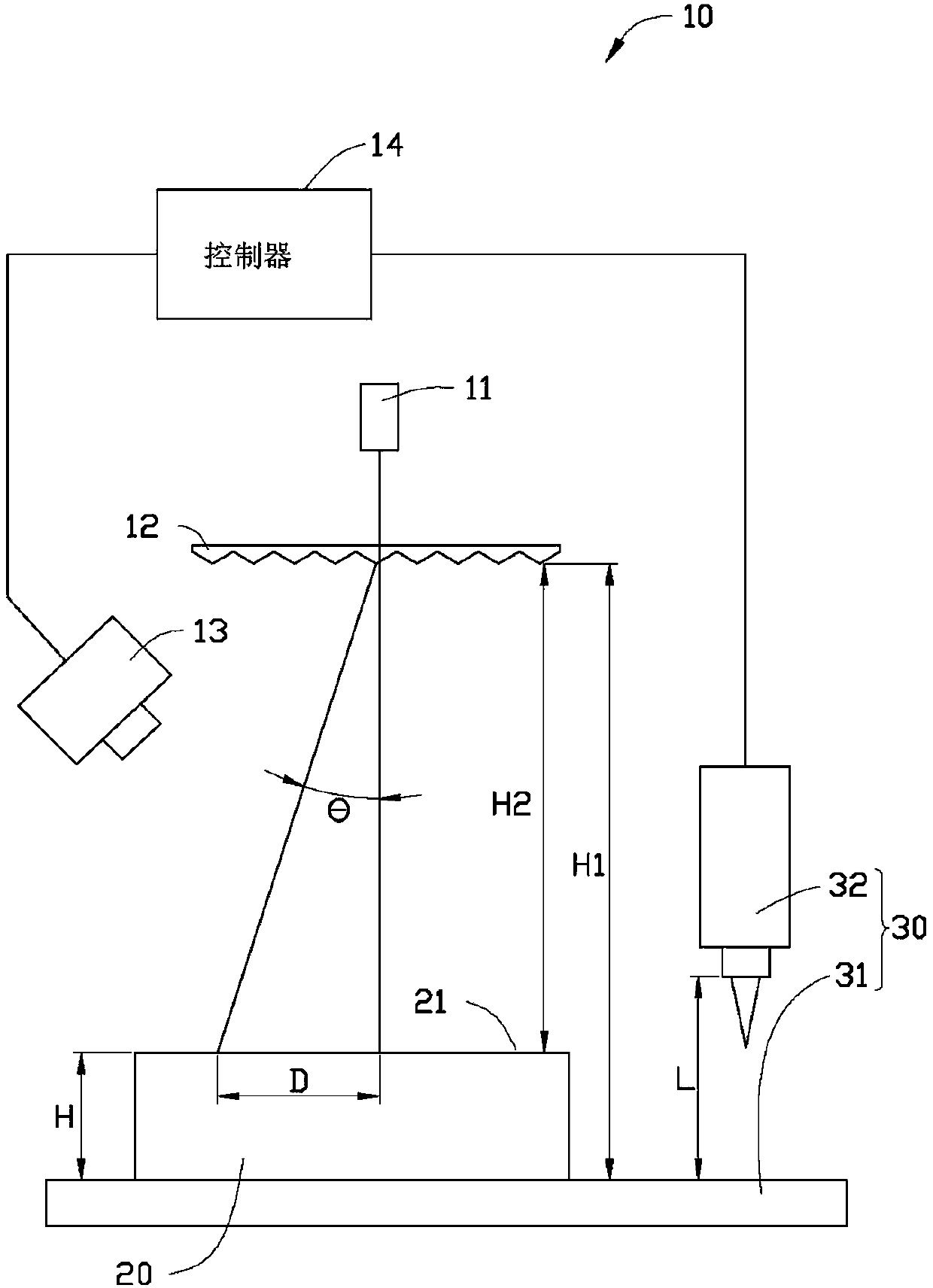

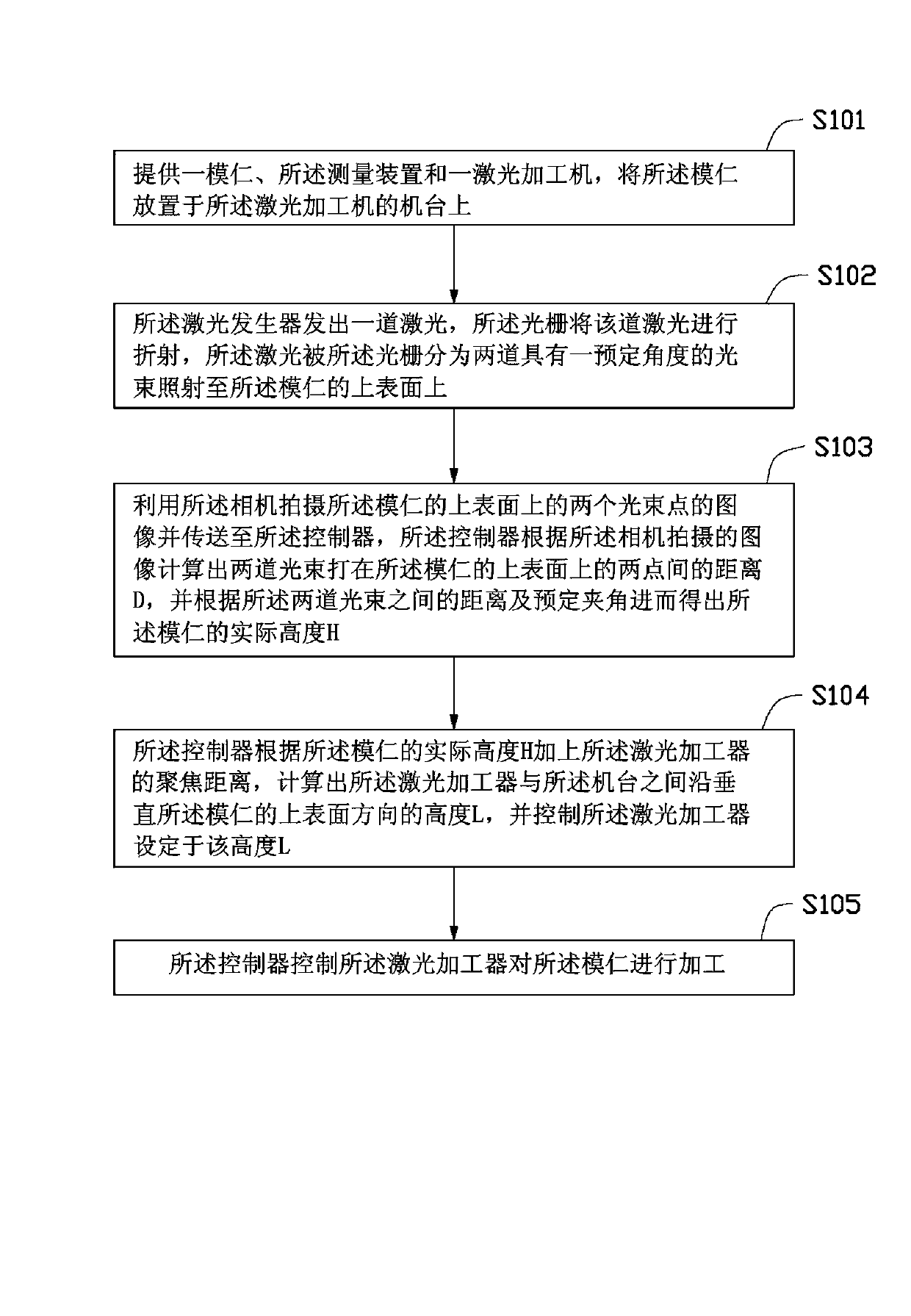

[0014] see figure 1 , the measuring device 10 of the present invention is used to measure the height of a mold kernel 20 before processing. The measuring device 10 is arranged above a laser processing machine 30 . The laser processing machine 30 includes a machine table 31 and a laser processing device 32 . The mold core 20 is carried on the machine table 31 .

[0015] The measuring device 10 includes a laser generator 11 , a grating 12 , a camera 13 and a controller 14 .

[0016] The laser generator 11 is fixed above the mold core 20 , and the laser emitted by it is perpendicular to an upper surface 21 of the mold core 20 .

[0017] The grating 12 is fixed between the laser generator 11 and the mold core 20, and the grating 12 is used to divide the laser light emitted by the laser generator 11 into two beams with a predetermined angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com