Small bearing rivet cage decomposition mold and its decomposition method

A bearing cage and cage technology, applied in the field of bearings, can solve the problems of knocking on inner and outer rings, secondary scars, and inability to be used as genuine products, so as to improve accuracy and authenticity rate, avoid secondary scars, and solve problems that are not easy to decompose Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

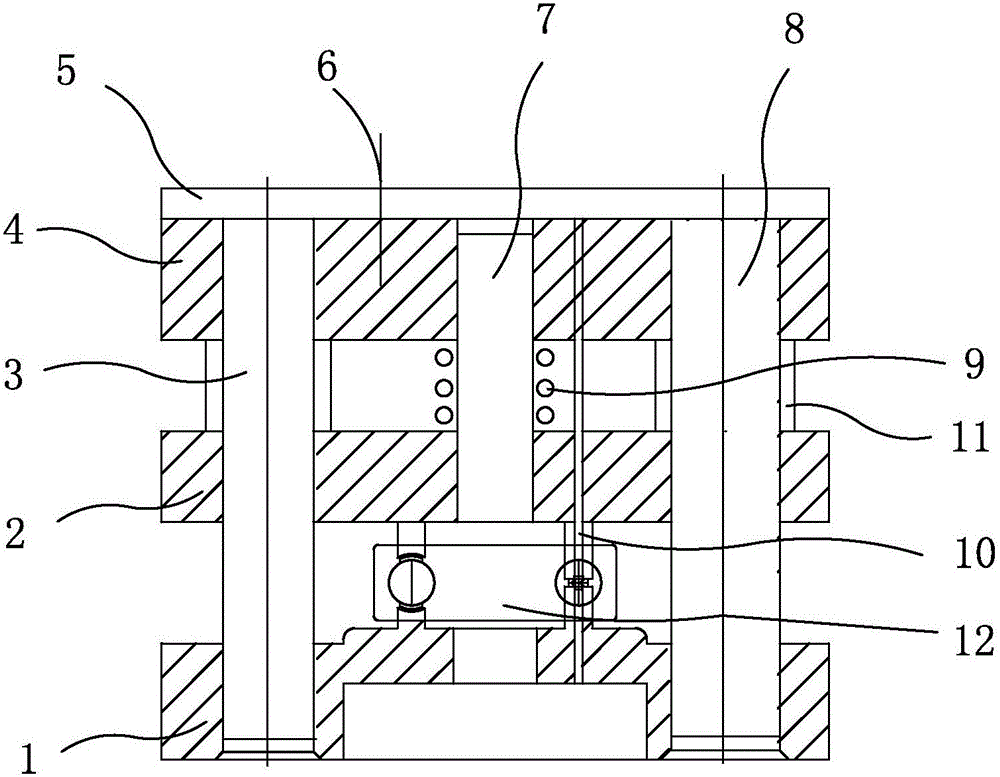

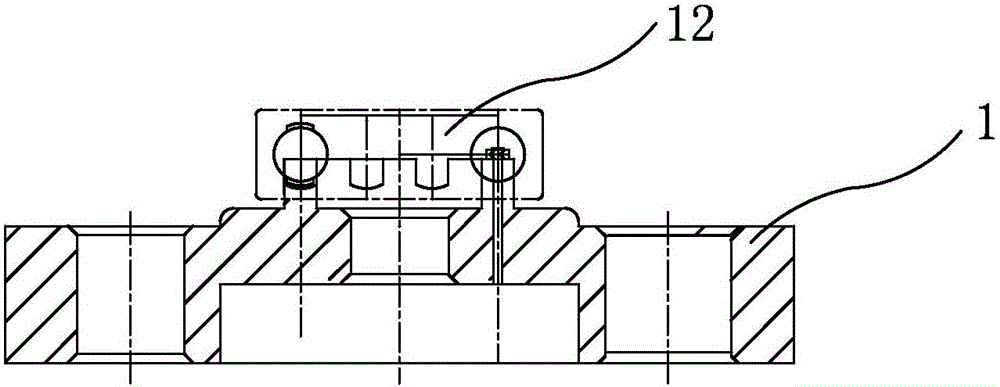

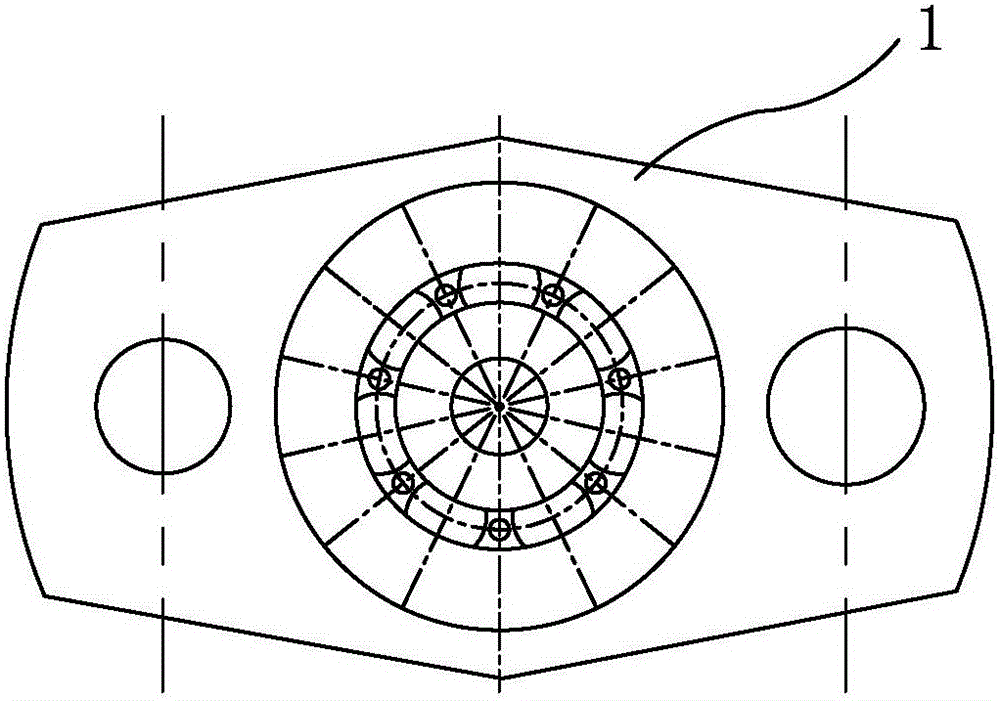

[0021] Combined with the above drawings, the name and serial number of the small bearing rivet cage decomposition mold parts of the present invention are: lower mold 1, upper mold 2, left guide post 3, sleeve removal mold assembly 4, end cover 5, countersunk head screw 6, guide Pin 7, right guide post 8, spring 9, nail removal pin 10, limit bushing 11, small bearing 12.

[0022] Such as Figure 1 to Figure 7 As shown, the implementation mode takes the small bearing rivet cage decomposition method for small bearings as an example. The rivet and cage decomposition process of the bearing rivet cage is as follows: the small bearing to be removed is placed on the lower mold 1, and the upper mold 2 Put the upper spring 9 on, and then install and remove the sleeve die assembly 4 along the left guide post 3 and the right guide post 8 holes of the upper die, and then adjust the upper and lower dies, and the sleeve die assembly 4, so that they are placed in the punching machine for stam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com