Fluorescent powder material with adjustable emitting color and preparation method thereof

A technology of luminescent color and fluorescent material, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of high color temperature and low color rendering of white LEDs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Another object of the present invention is to provide a method for preparing phosphor materials with tunable emission colors, but the present invention is not limited thereto. The method includes the following steps:

[0024] (1) According to the expression MLn 2 Si 3 o 10 :mBi 3+ , nEu 3+ The stoichiometric ratio of each substance in the formula is taken by weighing the elemental substances, oxides, halides and corresponding salts of Zn, Mg, Ca, Sr, Ba, La, Y, Si, Eu, Bi and corresponding salts respectively, where 0≤m ≤0.1,0≤m≤0.22.

[0025] The M is one or more of Zn, Mg, Ca, Sr and Ba, and Ln is one or more of Y and La;

[0026] (2) Mix the above-mentioned raw materials, and after fully grinding and mixing them in an agate mortar, put them into a corundum crucible, cover them, and wait for a high-temperature solid-phase reaction;

[0027] (3) Sintering the corundum crucible filled with mixed raw materials in a high-temperature muffle furnace at a sintering temp...

Embodiment 1

[0032] (1) According to the expression MLn 2 Si 3 o 10 :mBi 3+ , nEu 3+ , take M=Mg, Ln=Y, m=0.02, n=0.14, weigh MgO0.2015 grams, Y 2 o 3 1.1290 g, SiO 2 0.9012 g, Bi 2 o 3 0.0233, Eu 2 o 3 0.1232g, put it into an agate mortar and grind it thoroughly, put it into a corundum crucible, cover it, place it in a high-temperature furnace, heat it to 1250°C, keep the temperature constant for 6 hours, cool it naturally, take it out and grind it to get white MgY 2 Si 3 o 10 :0.02Bi 3+ ,0.14Eu 3+ phosphor material.

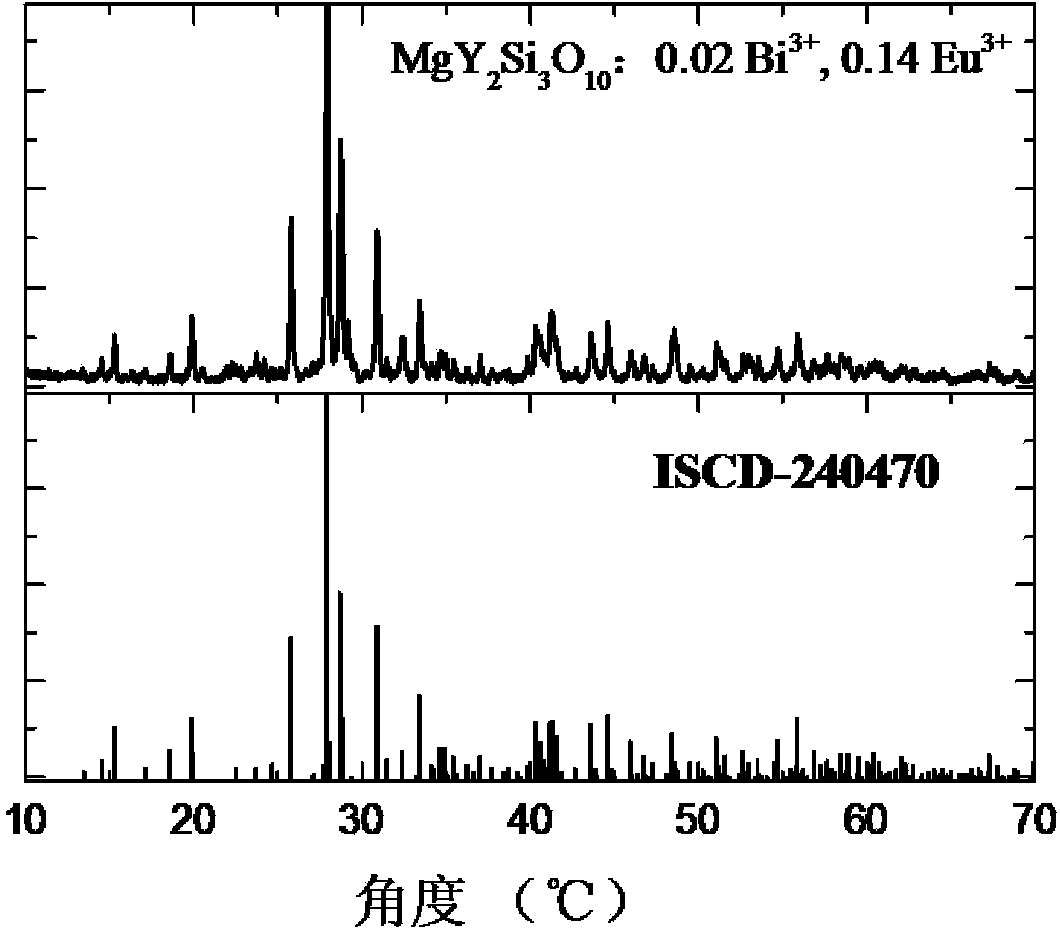

[0033] (2) combine figure 1 To illustrate embodiment 1, figure 1 It is the X-ray color atlas of the color-tunable phosphor material of Example 1 of the present invention, by figure 1 It can be seen that the diffraction peak position of the fluorescent material of the present invention is consistent with ISCD240470 in the crystallographic database, indicating the same structure.

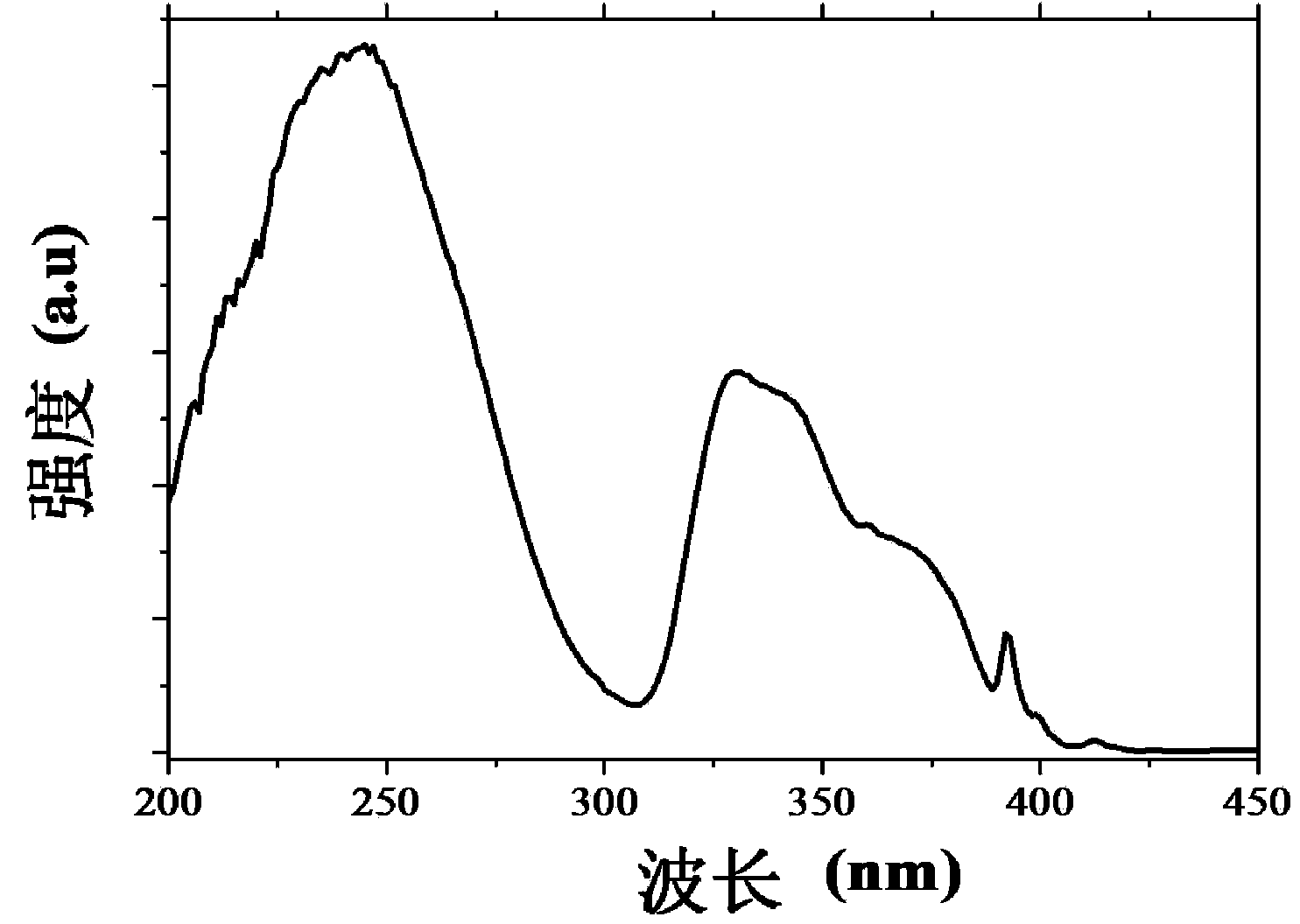

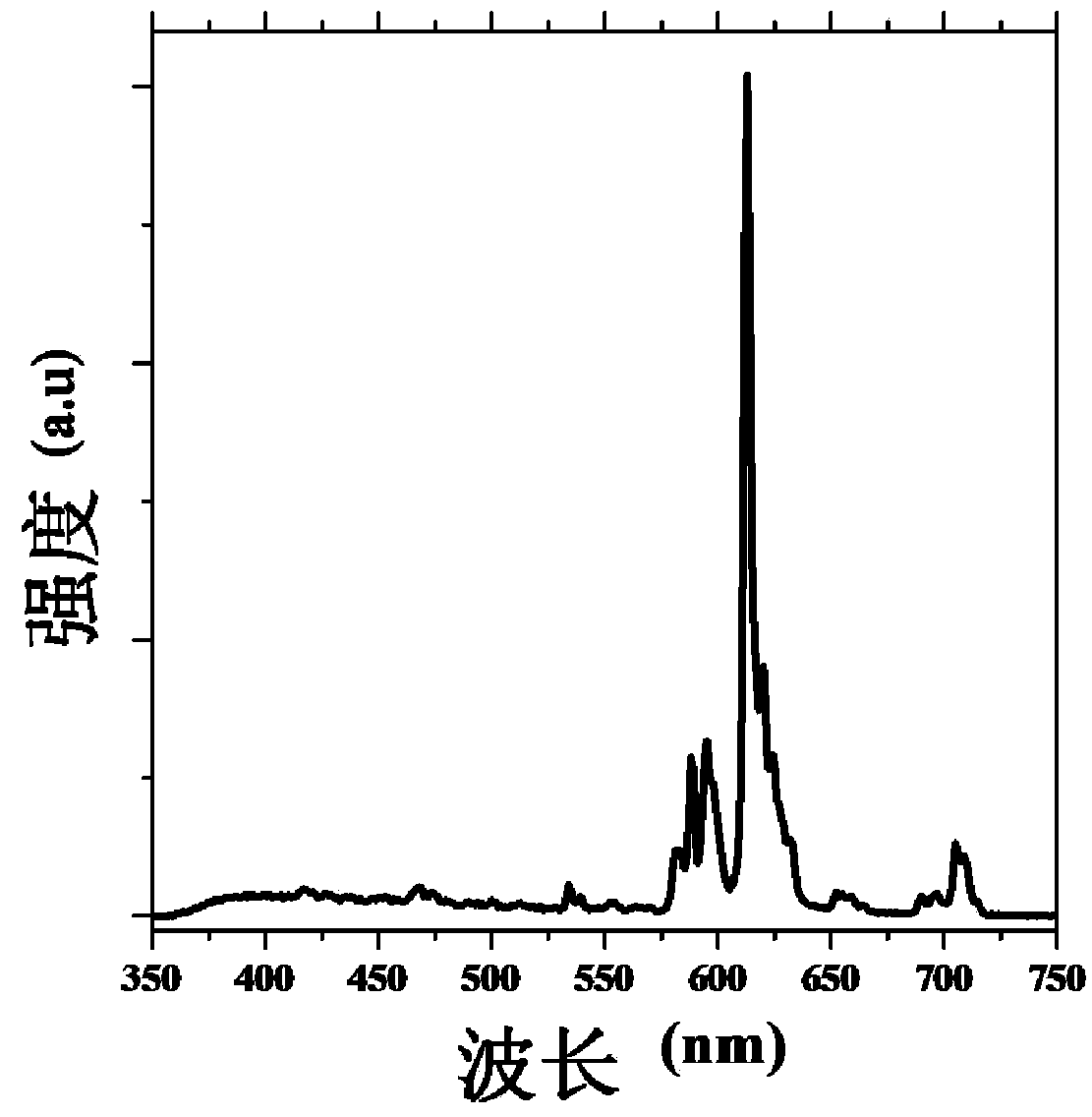

[0034] (3) combine figure 2 To illustrate embodiment 1, figure 2 is the e...

Embodiment 2

[0036] (1) According to the expression MLn 2 Si 3 o 10 :mBi 3+ , nEu 3+ , take M=Ba, Ln=Y, m=0, n=0.06, weigh 0.2015 grams of MgO, Y 2 o 3 1.1290 g, SiO 2 0.9012 g, Eu 2 o 30.0528g, put it into an agate mortar and grind it thoroughly, put it into a corundum crucible, cover it, place it in a high-temperature furnace, heat it to 1350°C, keep the temperature constant for 8 hours, cool it naturally, take it out and grind it to get white BaY 2 Si 3 o 10 :0.06Eu 3+ phosphor material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com