A kind of nitride near-infrared fluorescent material, preparation method and application thereof

A fluorescent material and near-infrared technology, applied in the field of fluorescent materials, can solve problems such as low quantum yield and achieve the effect of high quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] In the preparation method of the nitride near-infrared fluorescent material of the present invention, the raw material adopts the nitride corresponding to each element, for example: Ca 3 N 2 Powder, Sr 3 N 2 Powder, Ba 3 N 2 Powder, Li 3 N powder, Mg 3 N 2 Powder, AlN powder, Si 3 N 4Powder, it should be noted that the Eu source can use its nitride EuN, or Eu 2 O 3 , EuF 3 , or EuCl 2 powder, etc. The temperature for sintering and holding after mixing the raw materials is 800-1000°C, preferably 850-950°C, more preferably 865-935°C, such as 875°C, 880°C, 890°C, 900°C, or 915°C. The product obtained by sintering can be further heat-treated at a temperature of more than 500 ° C and less than 800 to 1000 ° C and kept in a hydrogen atmosphere for 1 to 10 hours to increase the Eu in the material. 2+ relative content.

[0059] Further, the product obtained by sintering can also be subjected to particle size adjustment and surface modification of the obtained flu...

Embodiment 1-14

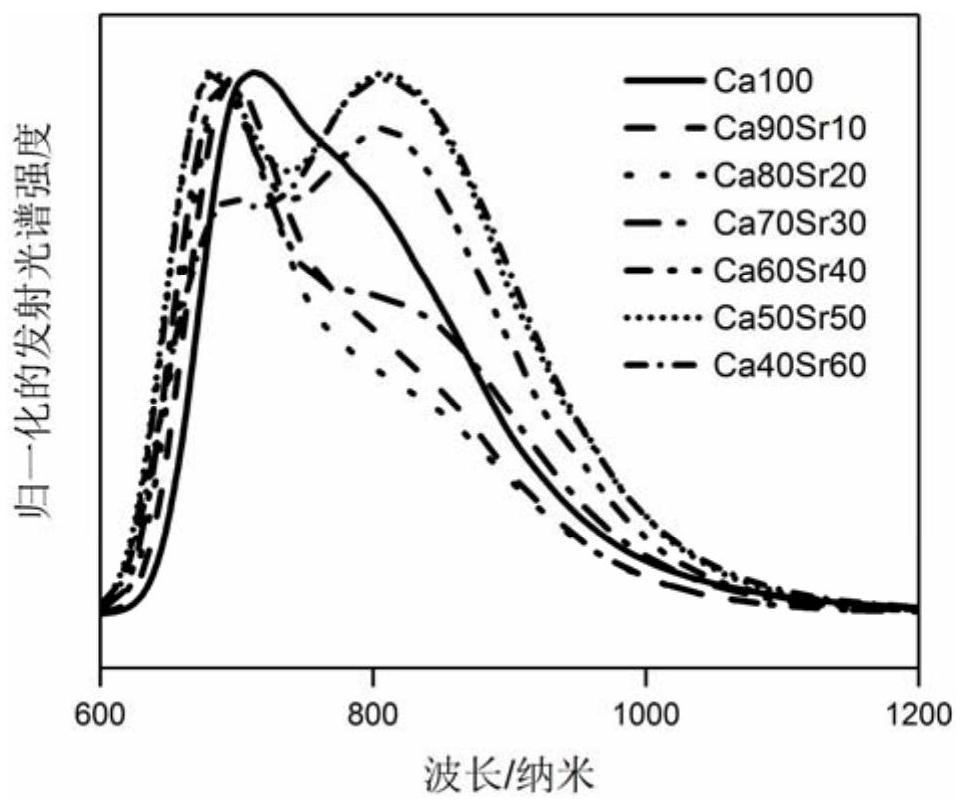

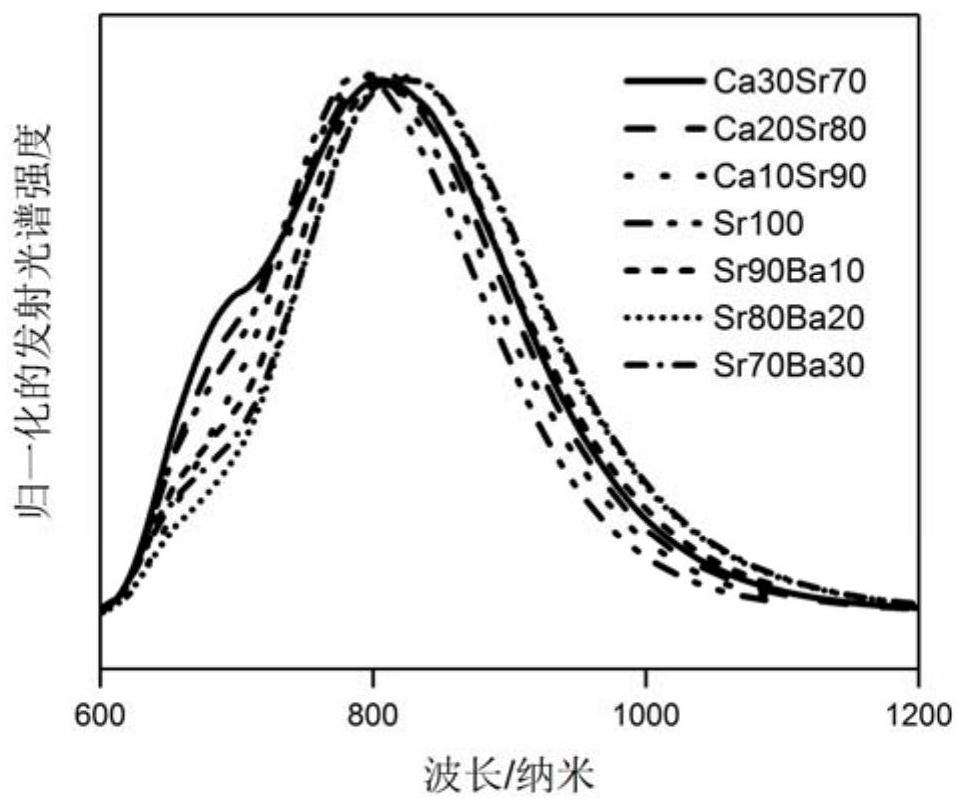

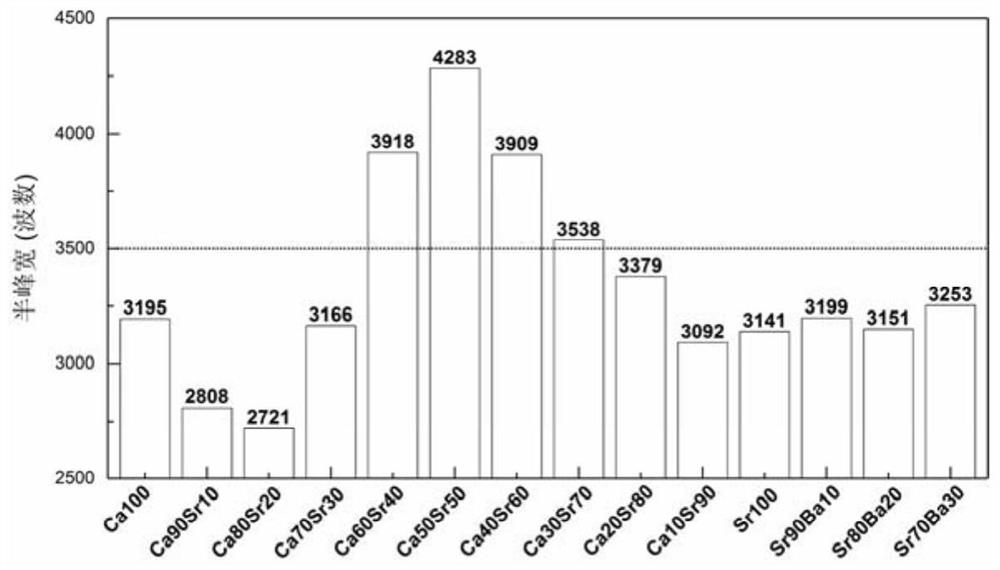

[0062] Examples 1-14 of the present invention provide 14 kinds of Eu 2+ Activated nitride near-infrared fluorescent materials, the chemical formulas are: (Ca 0.899 Sr 0.1 Eu 0.001 ) 3 [Li 4 Si 2 ]N 6 (abbreviated as Ca90Sr10), (Ca 0.799 Sr 0.2 Eu 0.001 ) 3 [Li 4 Si 2 ]N 6 (abbreviated as Ca80Sr20), (Ca 0.699 Sr 0.3 Eu 0.001 ) 3 [Li 4 Si 2 ]N 6 (abbreviated as Ca70Sr30), (Ca 0.599 Sr 0.4 Eu 0.001 ) 3 [Li 4 Si 2 ]N 6 (abbreviated as Ca60Sr40), (Ca 0.499 Sr 0.5 Eu 0.001 ) 3 [Li 4 Si 2 ]N 6 (abbreviated as Ca50Sr50), (Ca 0.399 Sr 0.6 Eu 0.001 ) 3 [Li 4 Si 2 ]N 6 (abbreviated as Ca40Sr60), (Ca 0.299 Sr 0.7 Eu 0.001 ) 3 [Li 4 Si 2 ]N 6 (abbreviated as Ca30Sr70), (Ca 0.199 Sr 0.8 Eu 0.001 ) 3 [Li 4 Si 2 ]N 6 (abbreviated as Ca20Sr80), (Ca 0.099 Sr 0.9 Eu 0.001 ) 3 [Li 4 Si 2 ]N 6 (abbreviated as Ca10Sr90), (Sr 0.999 Eu 0.001 ) 3 [Li 4 Si 2 ]N 6 (abbreviated as Sr100), (Sr 0.899 Ba 0.1 Eu 0.001 ) 3 [Li 4 Si 2 ]N ...

Embodiment 15-25

[0070] Embodiments 15-25 of the present invention provide 11 kinds of Eu 2+ Activated nitride near-infrared fluorescent materials, the chemical formulas are: (Sr 0.999 Eu 0.001 ) 3 [Li 3.9 Al 0.3 Si 1.8 ]N 6 , (Sr 0.999 Eu 0.001 ) 3 [Li 3.9 Mg 0.1 Al 0.1 Si 1.9 ]N 6 , (Sr 0.999 Eu 0.001 ) 3 [Li 3.8 Mg 0.1 Si 2 ]N 6 , (Sr 0.999 Eu 0.001 ) 3 [Li 3.8 Al 0.2 Si 1.9 ]N 6 , (Sr 0.999 Eu 0.001 ) 3 [Li 3.7 Mg 0.1 Al 0.3 Si 1.8 ]N 6 , (Sr 0.999 Eu 0.001 ) 3 [Li 3.7 Mg 0.2 Al 0.1 Si 1.9 ]N 6 , (Sr 0.999 Eu 0.001 ) 3 [Li 3.6 Mg 0.2 Si 2 ]N 6 , (Sr 0.999 Eu 0.001 ) 3 [Li 3.6 Mg 0.4 Si 1.8 ]N 6 , (Sr 0.999 Eu 0.001 ) 3 [Li 3.7 Al 0.1 Si 2 ]N 6 , (Sr 0.999 Eu 0.001 ) 3 [Li 3.6 Mg 0.1 Al 0.2 Si 1.9 ]N6 , (Sr 0.999 Eu 0.001 ) 3 [Li 3.4 Al 0.2 Si 2 ]N 6 .

[0071] Embodiments 15-25 of the present invention provide a Eu 2+ The preparation method of the activated nitride near-infrared fluorescent material includes:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com