A method for manufacturing a surface strengthening layer of a wear-resistant casting ball production mold and a mold having the same

A technology of surface strengthening layer and production method, which is applied in the direction of coating, casting mold, casting mold composition, etc., can solve the problems of high chromium content, high pouring temperature, and lower product quality of wear-resistant cast balls, and achieve anti-metal liquid burning Corrosion, improve process performance, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Ductile cast iron is used to cast iron molds for wear-resistant balls, and the molds are designed with cooling systems and exhaust systems.

[0039] The mold casting is machined to prepare it for the next step of nickel plating.

[0040] Nickel plating is carried out on the working surface of the mold, degreasing before plating, alkali cleaning, pickling, polishing surface roughness reaches △3.2, activated nickel plating, thickness above 70um.

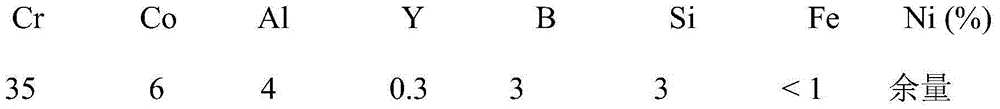

[0041] The strengthening layer material is made of alloy powder, the particle size is -140+320 mesh, and the specific composition is as follows:

[0042]

[0043] The alloy powder is dried at 120°C for 1 hour, and it is used for subsequent spraying.

[0044] Roughen the nickel-plated layer to obtain a rough surface, ready for the next step of spray welding.

[0045] Before spray welding, the mold base is preheated to 350°C.

[0046] Spray welding method: two-step oxyacetylene spray welding.

[0047] Both spraying and reme...

Embodiment 2

[0055] Ductile cast iron is used to cast iron molds for wear-resistant balls, and the molds are designed with cooling systems and exhaust systems. The mold casting is machined to prepare it for the next step of nickel plating.

[0056] The working surface of the mold is nickel-plated, degreased before plating, alkali-washed, pickled, polished surface roughness reaches △3.2, activated nickel-plated, thickness above 75um.

[0057] The strengthening layer material is made of alloy powder, the particle size is -140+320 mesh, and the specific composition is as follows:

[0058]

[0059] Dry the powder at 120°C for 1 hour, and prepare it for subsequent spraying.

[0060] Roughen the nickel plating to obtain a rough surface, ready for the next step of spray welding.

[0061] Before spray welding, the mold base is preheated to 350°C.

[0062] Spray welding method: plasma spray welding.

[0063] The spray welding process is as follows:

[0064] Protective gas argon, flow rate 3...

Embodiment 3

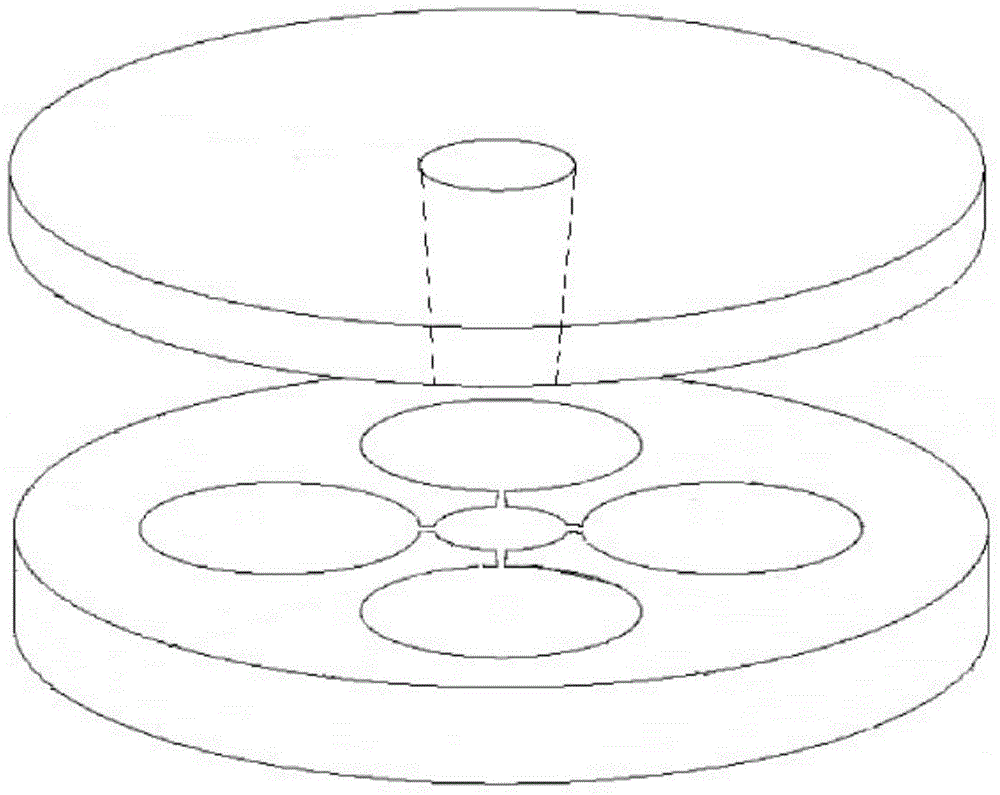

[0073] Such as figure 2 Shown is a mold. The surface reinforcement layer is prepared by the above method on the working surface of the mold. The working surface includes the inner wall of the sprue gate, the surface of the wear-resistant ball cavity, and the surface of the molten iron buffer tank.

[0074] After adopting the above scheme, the high temperature resistant strengthening layer formed on the surface of the casting mold plays the role of preventing the ablation and adhesion of the metal solution.

[0075] The high temperature resistant strengthening layer has the advantages of good thermal conductivity, high temperature resistance, and the functions of preventing ablation and adhesion of molten metal. The combination strength of the coating and the mold is high, which greatly improves the service life of the mold.

[0076] The surface-strengthened mold does not need to brush the release agent before each casting, which reduces the labor intensity and makes the mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com