Combined lattice type hollow component

A lattice structure and hollow technology, applied to building components, long strip structural components for load-bearing, structural elements, etc., can solve the problems of increasing the self-weight of the structure, achieve the goals of reducing the self-weight of the structure, facilitating construction, and improving the bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

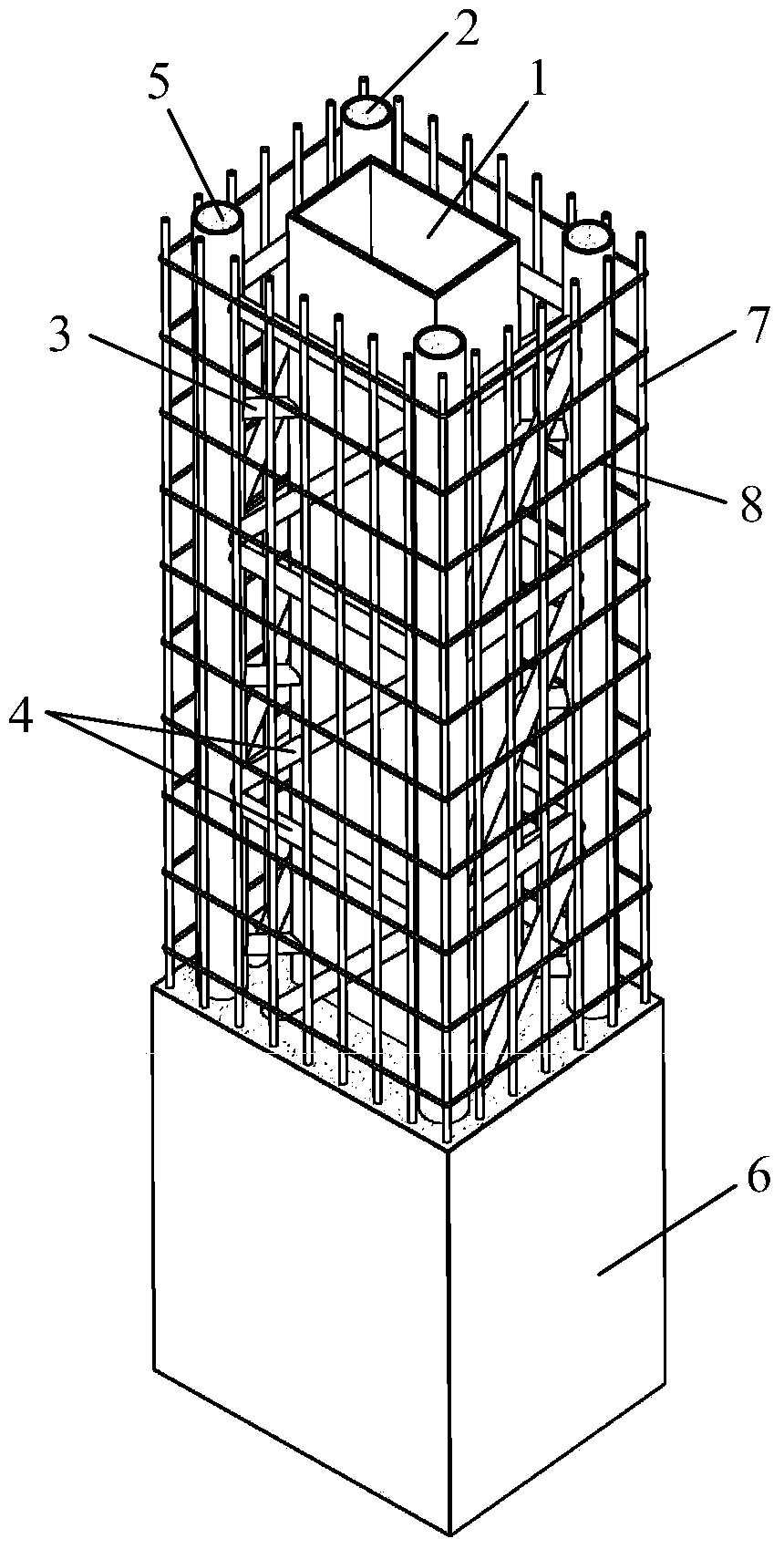

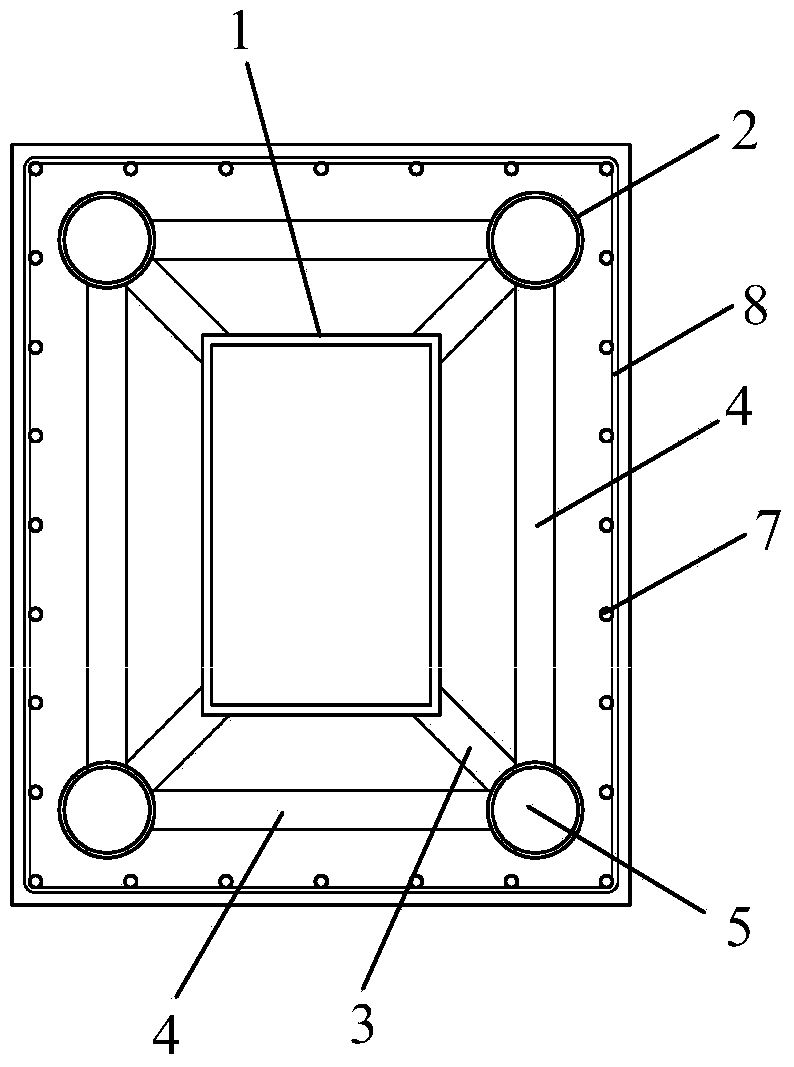

[0016] like figure 1 and figure 2 As shown, in order to see the internal structure of the combined lattice hollow member more clearly in this embodiment, the outer concrete cladding layer is removed from the upper section of the member. As can be seen from the figure, this embodiment includes an inner steel pipe 1, a plurality of outer steel pipes 2, inner web bars 3, outer web bars 4, and a concrete filling layer 5 and a concrete cladding layer 6; the outer steel pipe 2 Set around the periphery of the inner steel pipe 1, the inner steel pipe 1 is connected to the outer steel pipe 2 through the inner web rod 3, and the adjacent outer steel pipe 2 is connected through the outer web rod 4, and the concrete filling layer 5 is filled in the Referring to the inside of the outer steel pipe 2, the concrete cladding layer 6 completely covers the inner steel pipe 1, the outer steel pipe 2, the inner web bar 3 and the outer web bar 4. The concrete cladding layer 6 is also provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com