Automatic positioning system of underground mining drill carriage

An automatic positioning and drilling rig technology, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc., can solve the problems of waste of energy and resources, low hole layout accuracy, and poor hole forming accuracy, so as to save energy costs , Fast positioning ability, avoiding waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

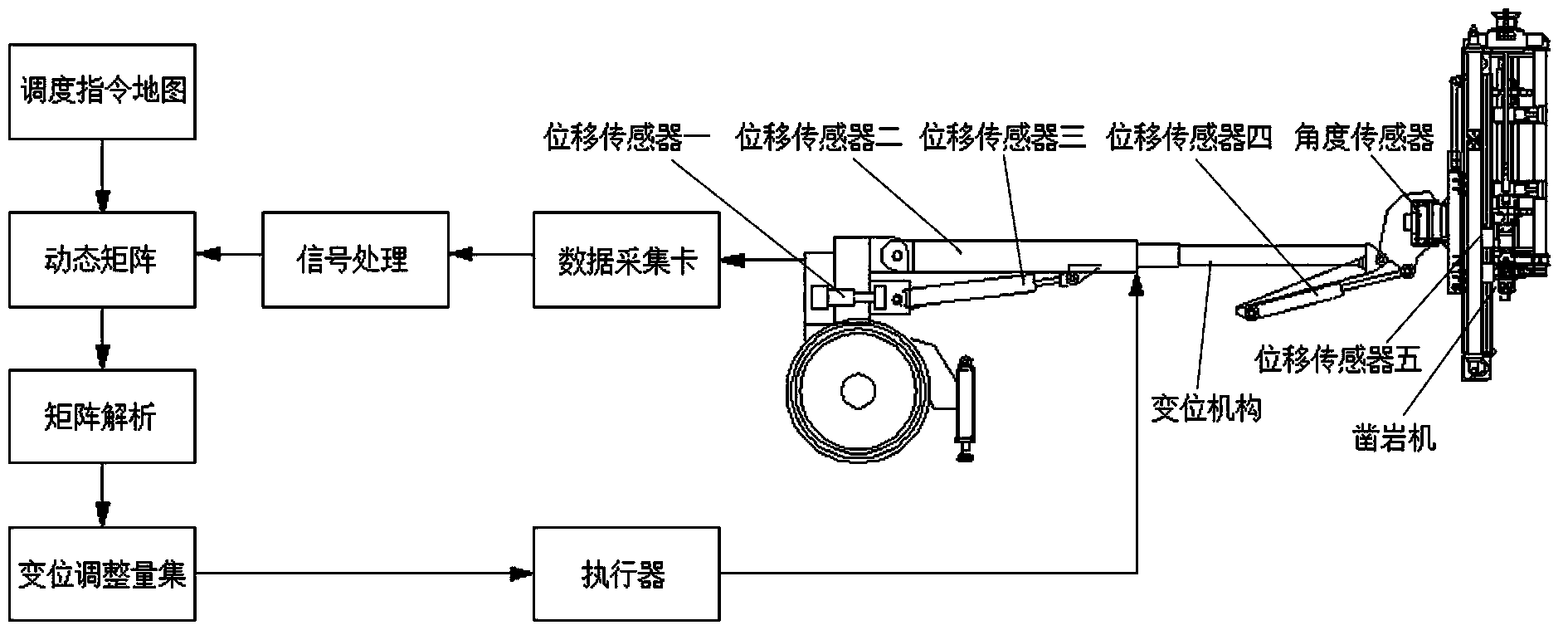

[0016] The invention realizes the automatic positioning of the blasting hole position of the underground mining drill car through the control of the displacement mechanism, and realizes the automatic adjustment of the attitude adjustment amount of the displacement mechanism through the identification of the hole layout instruction and the attitude position of the mining drill vehicle by the industrial computer.

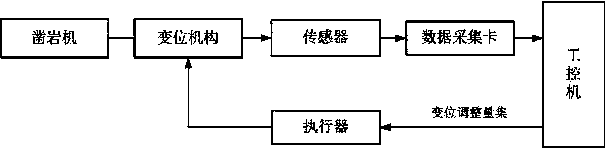

[0017] Such as figure 1 As shown, the present invention includes a rock drilling machine, a displacement mechanism, an industrial computer, a sensor module for determining the posture and position of a mining drilling rig, a data acquisition card and an actuator. The output end of the sensor module is connected to the input end of the data acquisition card through a cable, the output end of the data acquisition card is connected to the serial port of the industrial computer, the industrial computer is connected to the actuator through the RS-232 interface, and the actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com