Paper box molding, positioning and processing control method and positioning control system

A control method and positioning control technology, which are applied in the control without feedback, box making operation, rigid/semi-rigid container manufacturing, etc., can solve the problems of difficult mechanization of the manufacturing process, low manual positioning accuracy and high cost, and achieve The effect of enhancing market competitiveness, convenient system maintenance and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

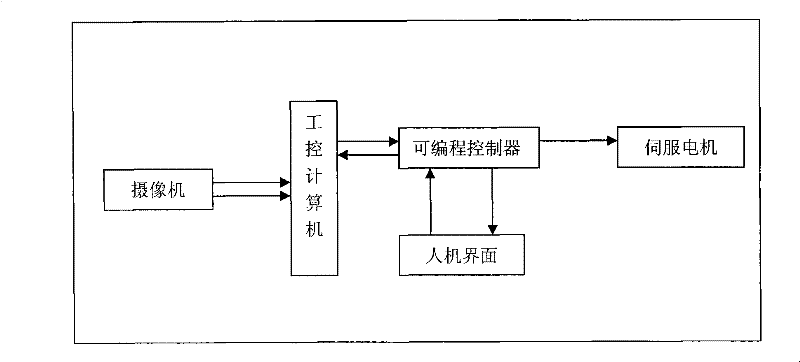

[0026] In this embodiment, the high-performance industrial control computer adopts the Lenovo Tiangong Pentium4 processor and provides 512 megabytes of memory; it adopts the FP-X series programmable controller of Panasonic Company, and has two 100K and two 20K pulse outputs; it adopts the Panasonic A4 series Servo system, Panasonic A4 series high-performance AC servo motor, can reach 1KHz speed response frequency.

[0027] see figure 1 , the overall process of the system is as follows: the camera transmits data to the industrial control computer individually, uses the digital signal conversion device to complete the data and signal transmission between the industrial control computer and the programmable controller, calls or inputs new parameters or The control program improves its function and is finally transferred to the servo motor for execution.

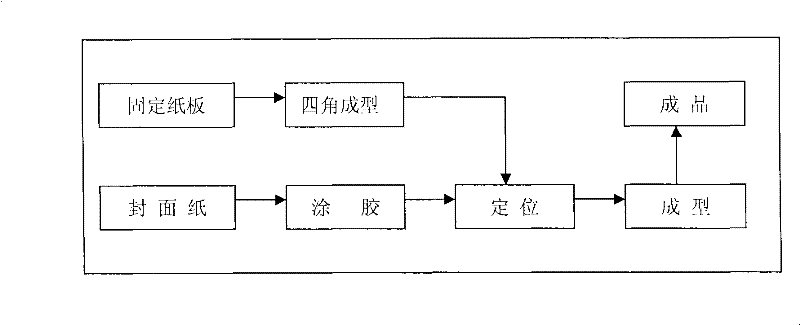

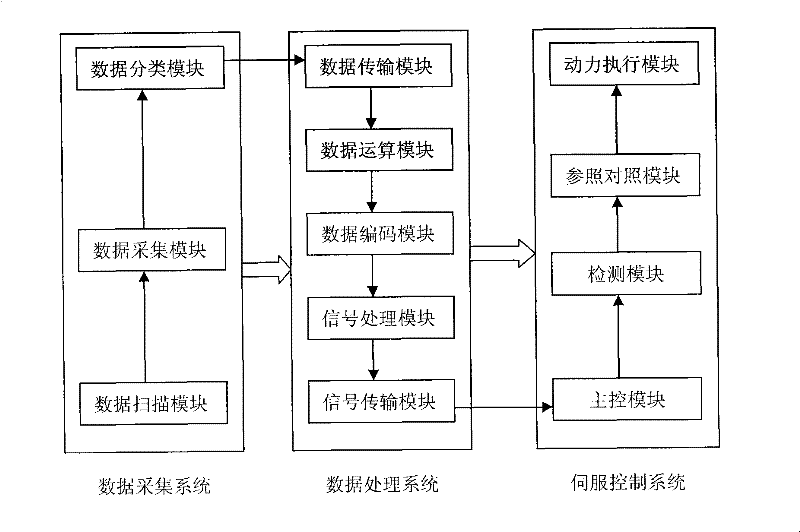

[0028] see figure 2 and Figure 4 , a control method for carton forming and positioning processing, which includes a proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com