Design method of high-fidelity non-uniform shark-imitating groove microstructure of large cooing tower fan blade

A design method and tower fan technology, applied in the field of engineering bionics, can solve the problems of limited reliability and life of the whole machine, low fidelity, large differences, etc., and achieve the effect of ensuring the actual use effect and efficient actual use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

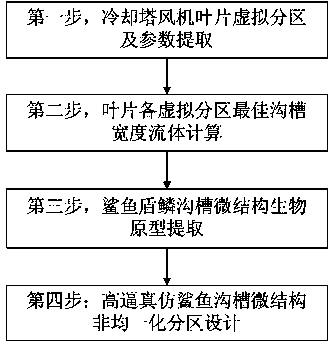

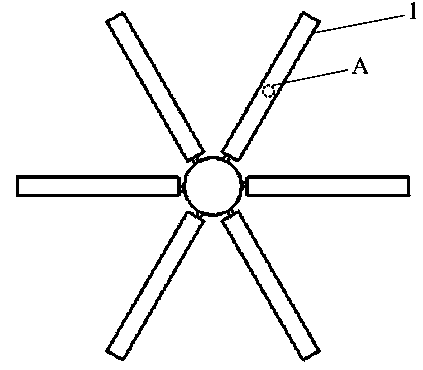

[0038] refer to Figure 1 ~ Figure 3 , to be in accordance with figure 1The process shown is to design a high-fidelity, non-uniform shark-like groove microstructure on a large six-bladed, standard-finned cooling tower fan blade. The relevant dimensions and working parameters of this type of cooling tower fan blade are: the length of a single cooling tower fan blade 1 is 10m, the diameter of the wheel is 2.5m, and the design rated speed is 110rpm.

[0039] Step 1: Virtual partitioning of cooling tower fan blades and parameter extraction.

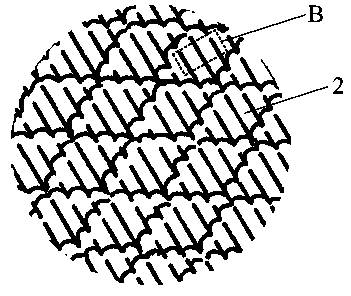

[0040] refer to figure 2 , Figure 4 First, it is determined that the design of the shark-like groove microstructure 2 is only carried out on the front and back of the blade al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com