Hydraulic oil tank for hydraulic system

A hydraulic oil tank and hydraulic system technology, which is applied in the direction of fluid pressure actuation system components, oil supply tank devices, fluid pressure actuation devices, etc., can solve the problems of short service life and poor effect, and achieve purity assurance, convenient use, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

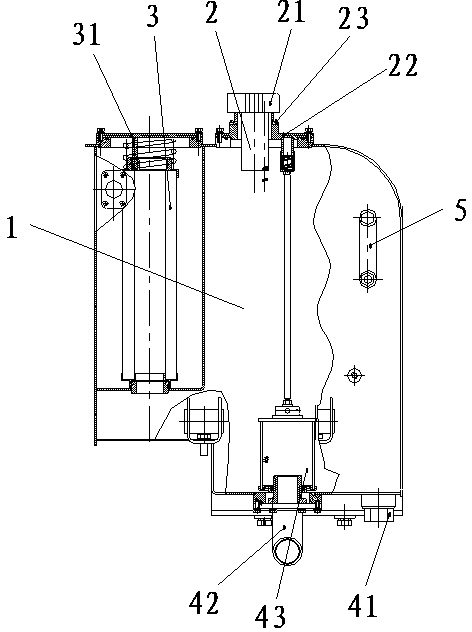

[0021] as attached figure 1 As shown in the schematic diagram of the structure of the present invention, a hydraulic oil tank for a hydraulic system includes a tank 1, a fuel filler 2 fixed on the upper part of the tank 1, an oil return filter element 3 installed on one side of the tank 1, The screw plug 41 installed on the bottom of one side of the box body 1 and the oil suction joint 42 installed on the bottom of the box body 1 and located on one side of the screw plug 41, the oil filler port 2 is equipped with a filler filter 21. A fuel filler flange 22 is fixedly installed on the outside of the filler port 2, and a flange 31 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com