Oil Depot Pipeline Leak Detection Method

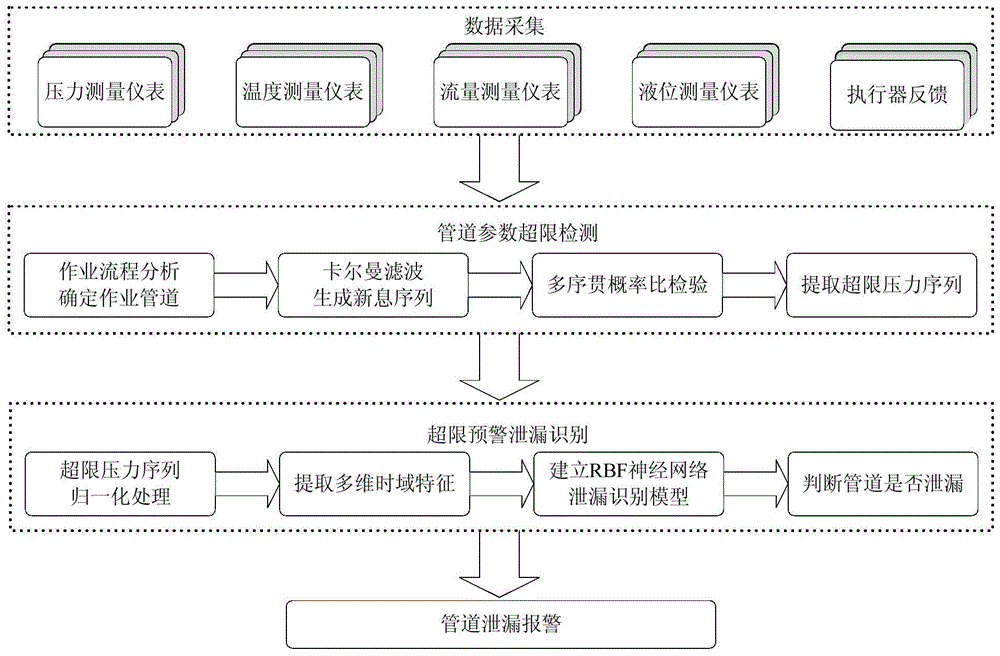

A technology of leak detection and detection method, which is applied in pipeline system, mechanical equipment, gas/liquid distribution and storage, etc. It can solve the problems of high false alarm rate, inability to adjust to normal working conditions, low cost of leak detection, etc., and achieve reduction False alarm rate, the effect of improving the ability to adapt to changes in working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

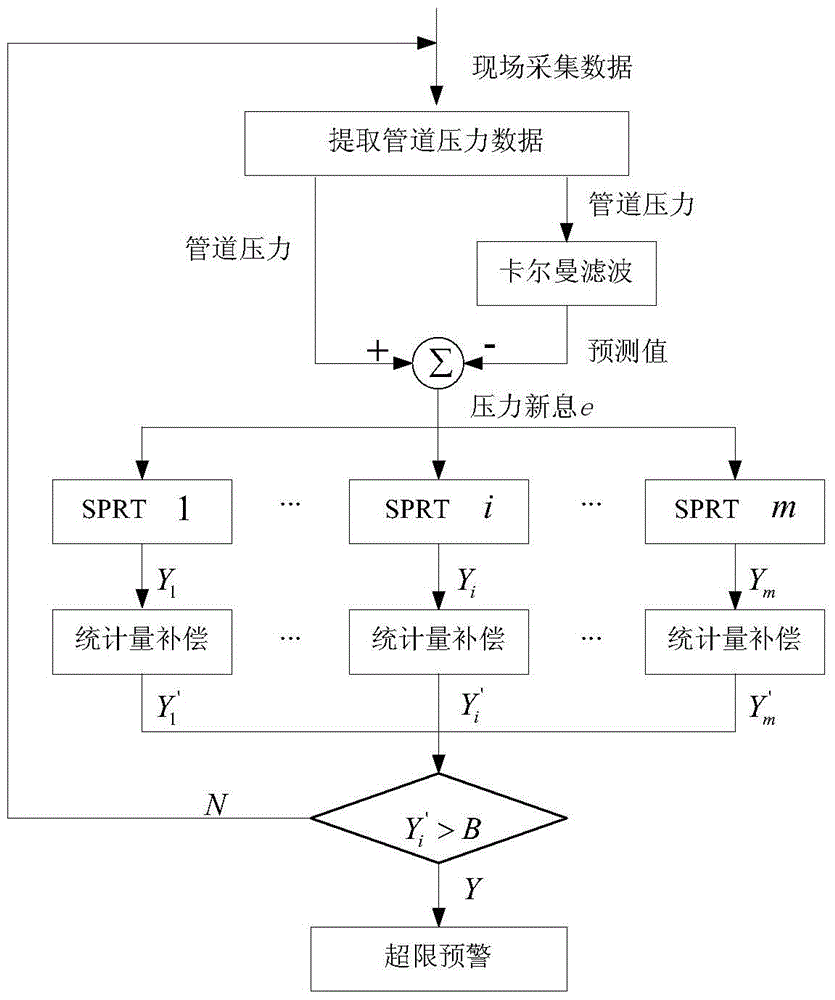

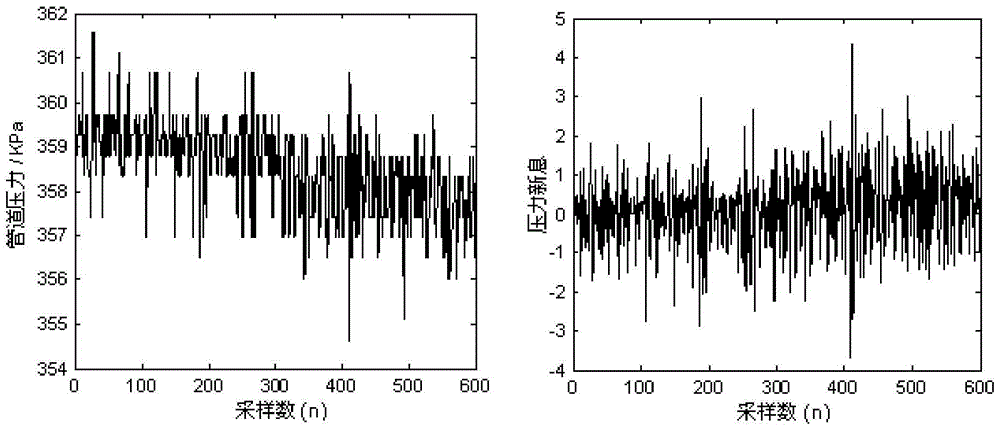

[0043] Embodiment. Take this example to illustrate the specific implementation of the present invention. First, analyze the process flow of the oil depot and the current operation mode, collect the pressure data p of the operation pipeline, and perform Kalman filtering to generate pressure innovation e. The pipeline pressure and standardized pressure innovation sequence are as follows: image 3 shown.

[0044] Hypotheses on the distribution mean μ of the standardized pressure innovation e

[0045] h 0 :μ=0、H 1 :μ=θ i

[0046] θ i is the alternative hypothesis value, respectively 0.1, 0.2, 0.3, 0.4 in the embodiment, the alternative hypothesis θ is calculated after each sampling i The test statistic Y i (k) as follows:

[0047]

[0048] Calculate the modified test statistic Y after introducing the compensation amount U i '(k):

[0049] Y i '(k)=Y i (k)+U i=1,2,...,m

[0050]

[0051] It is stipulated that the false alarm rate α=0.05 and the false negative rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com