LED light source system

An LED light source and LED chip technology, applied in the field of light sources, can solve the problems of reduced brightness, increased etendue, acquisition of LED chips, etc., to achieve the effects of reducing waste, reducing etendue, and improving brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

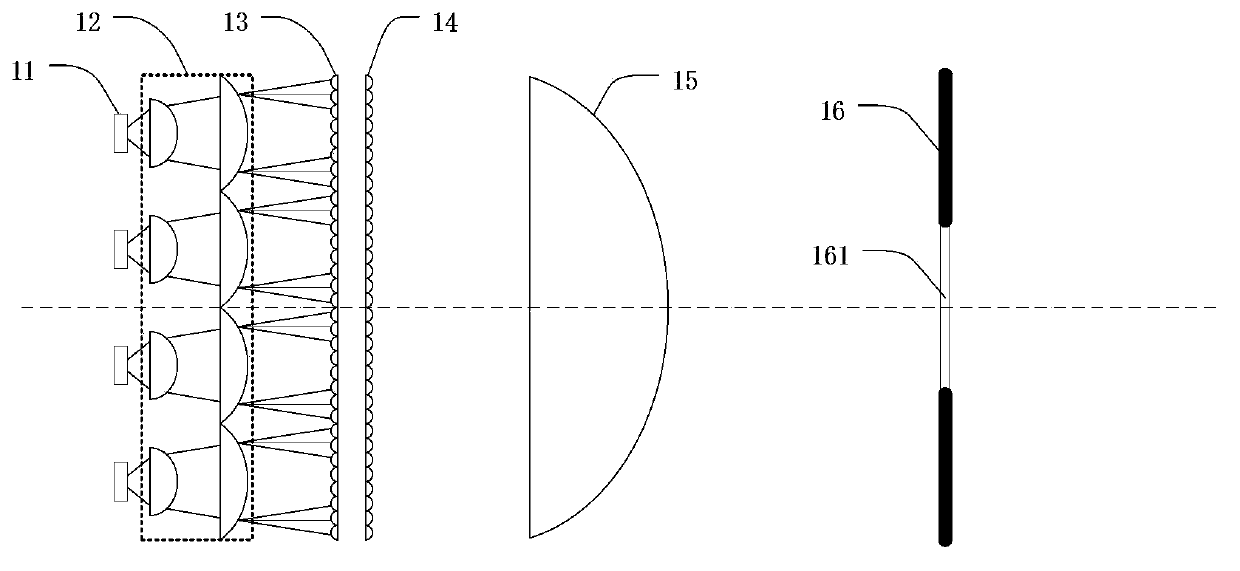

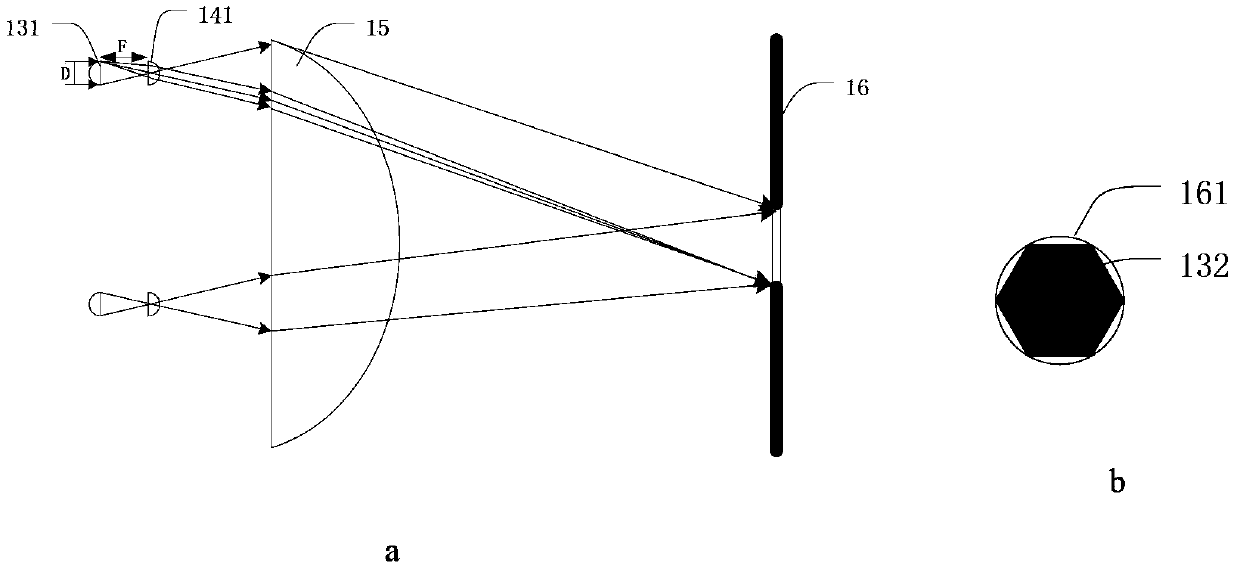

[0034] The overall structure of the light source system of this embodiment is as follows Figure 4 shown. The light source system includes an LED chip array, the LED chip array includes at least two LED chips 41, and the light emitting surface of each LED chip 41 is square. The light source system also includes a collimating lens array 42 positioned behind the LED chip array. The collimating lens array 42 includes at least two collimating lenses, and each collimating lens corresponds to at least one LED chip, and is used to correct the light beam emitted by the LED chip array. Collimating; in this embodiment, a collimating lens is realized by placing two lenses front and back to form a lens group. The light source system also includes a first fly-eye lens 43 positioned behind the collimating lens array 42, the first fly-eye lens 43 includes a regular hexagonal microlens array closely arranged; it also includes a second fly-eye lens 44 positioned at the rear focal plane of the...

Embodiment 2

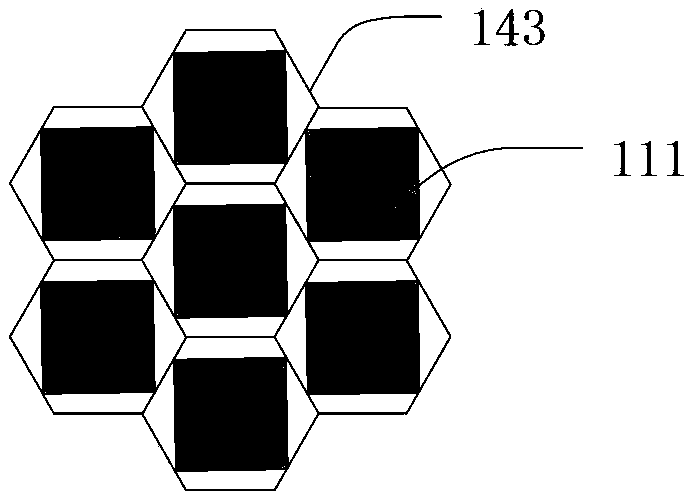

[0043] In the first embodiment, the image of the LED chip cannot be filled in the long side direction of the rectangular microlens, and the etendue is still wasted. In this embodiment, the divergence angle of the LED along the two mutually perpendicular sides of the LED chip after passing through the collimating lens is a predetermined value. According to the formula (1), as long as the LED is controlled to pass through the collimating lens The divergence angle on two mutually perpendicular edge directions is predetermined value, just can control the aspect ratio of the image that LED chip forms on the rectangular microlens of second fly-eye lens; Make this aspect ratio equal to the aspect ratio of rectangular microlens In this way, the image of the LED chip can completely fill the rectangular microlens, and the brightness is the highest at this time.

[0044] For example, the aspect ratio of the rectangular microlens 143 is at most At this time, the corresponding rectangula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com