Evaporator and defrosting device thereof

A technology for evaporators and evaporator tubes, applied to evaporators/condensers, defrosting, electric heating devices, etc., can solve problems such as increased energy consumption, rise in the temperature of the freezer space, and the need to increase the cooling capacity of refrigerators, etc., to reduce Energy consumption, effect of improving defrosting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

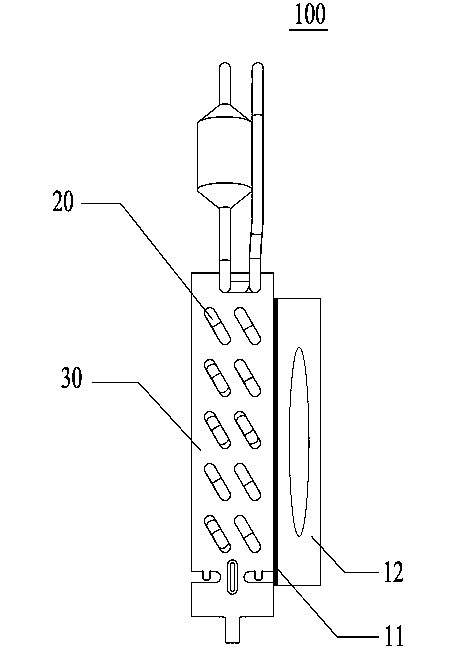

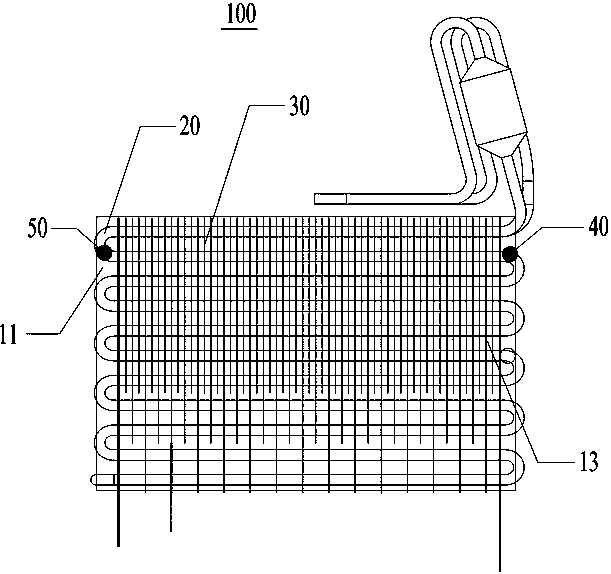

[0020] ginseng figure 1 , to introduce a specific embodiment of the evaporator defrosting device of the present invention. In this embodiment, the evaporator defrosting device includes an electromagnetic heating module 12 and a metal heating element.

[0021] The electromagnetic heating module 12 usually includes an excitation coil (not shown in the figure). When current passes through the electromagnetic heating module 12 , an alternating magnetic field is generated around the excitation coil due to the principle of electromagnetic induction. The electromagnetic heating module 12 is arranged in coop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com