Coaxial coil electromagnetism propulsion system

An electromagnetic propulsion and coaxial coil technology, which is applied to electromagnetic launchers, offensive equipment, weapons without explosives, etc. Precisely control the launch, limit the practicability of the coil gun, etc., to achieve the effect of uniform distribution of induced current, low temperature rise at the tail, and reduced difficulty and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

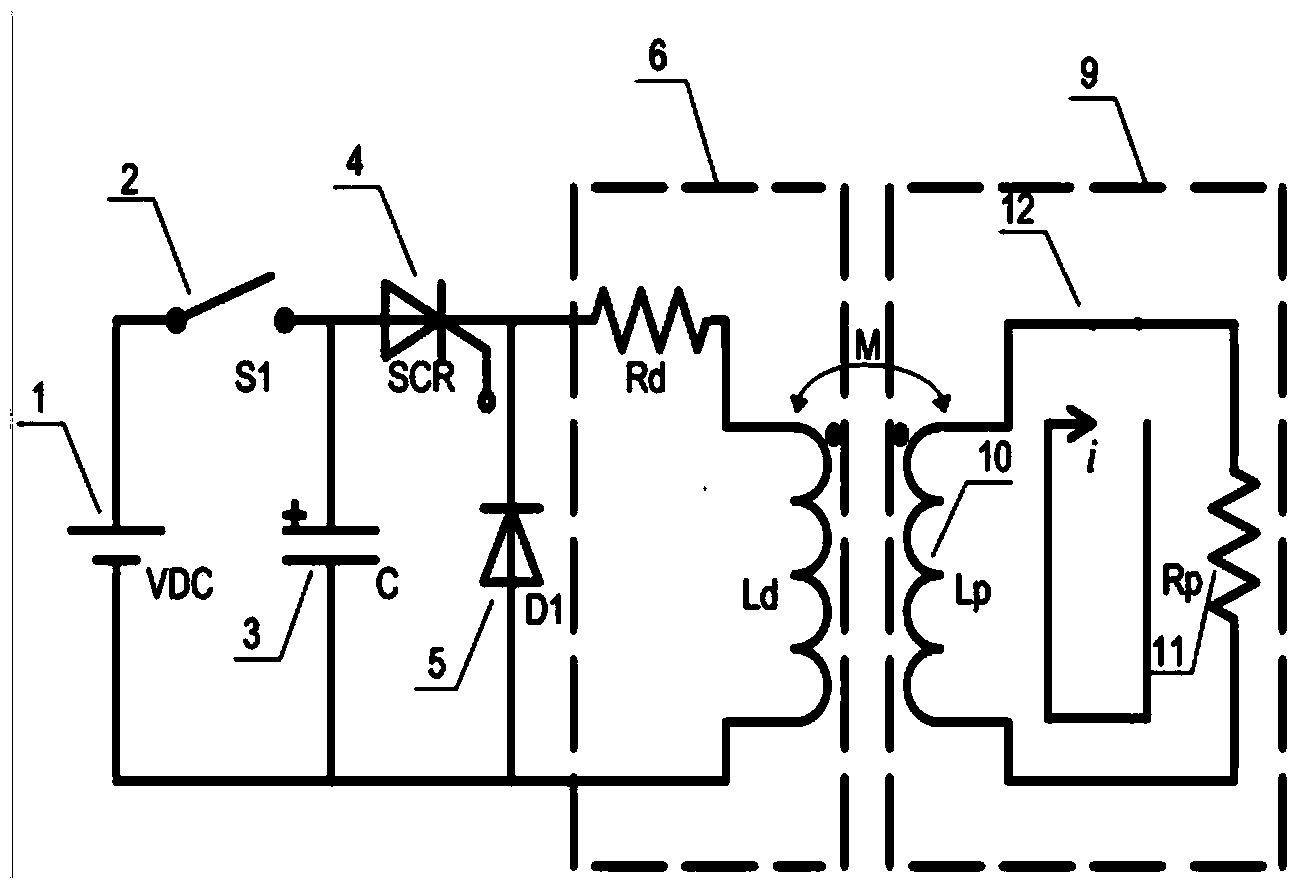

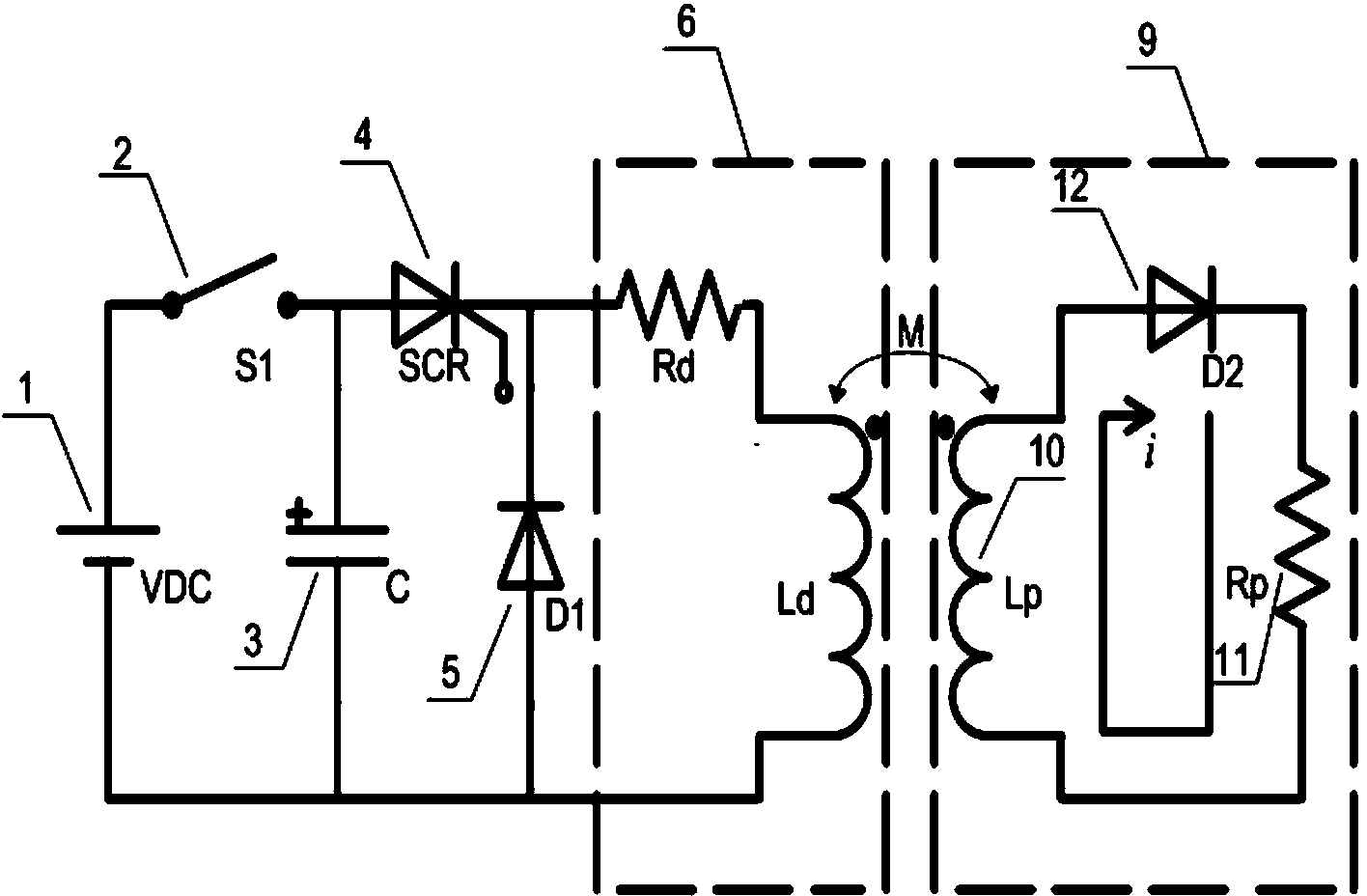

[0018] Such as figure 2 As shown, the relevant parameters of the circuit are as follows:

[0019] High-voltage DC charging power supply: 10kV;

[0020] Pulse capacitor: C=100uF, Uc=6kV;

[0021] Drive coil: internal resistance Rd=0.2Ω, self-inductance Ld=0.296mH;

[0022] Projectile armature: internal resistance Rp=30mΩ, self-inductance Lp=4.1nH;

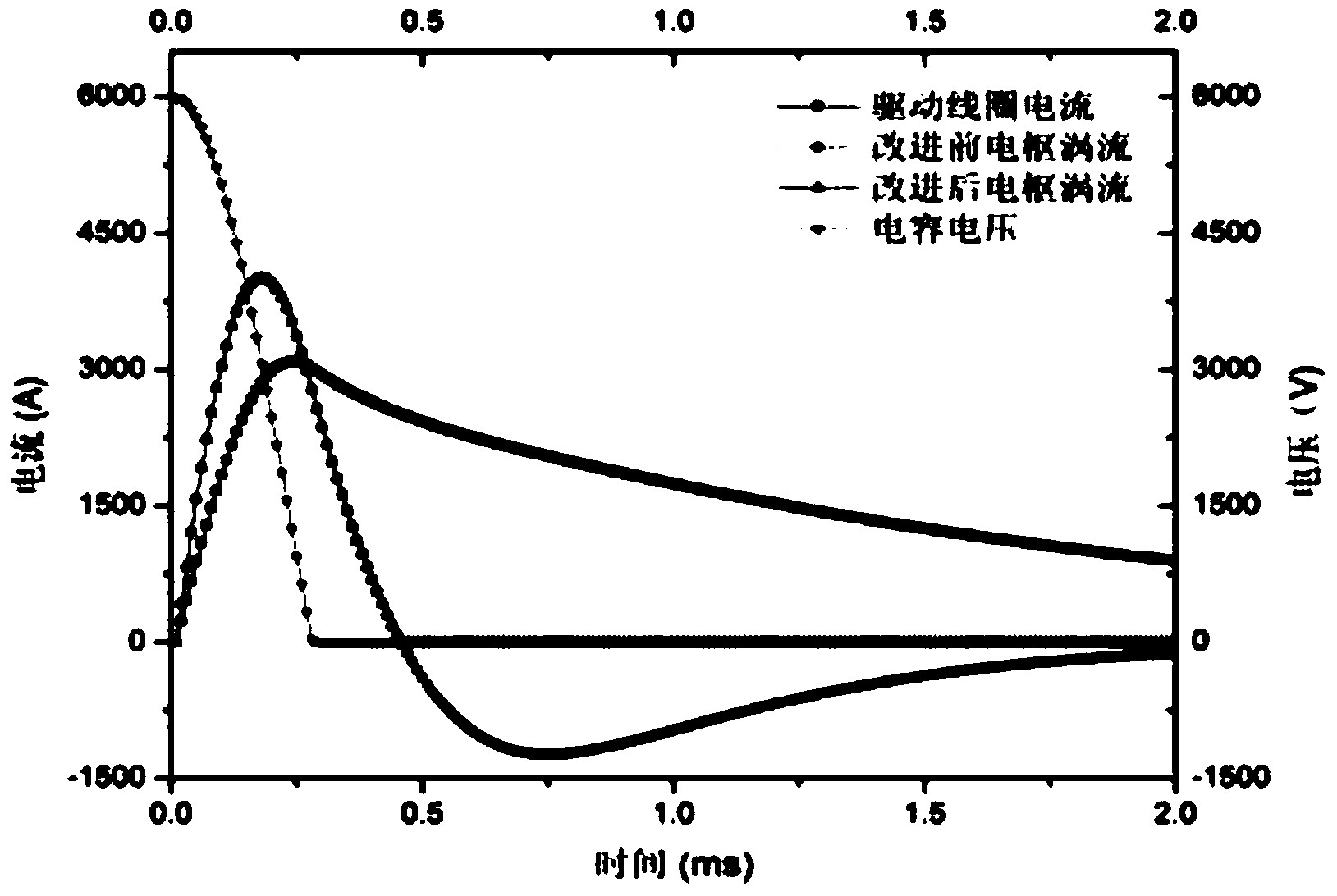

[0023] Such as image 3 As shown, charge the pulse capacitor to the preset voltage of 6kV with a high-voltage DC charging power supply, turn off the switch S1, and the energy storage of the pulse capacitor is completed; within 0~0.28ms, the pulse capacitor discharges the driving coil, and the voltage of the pulse capacitor drops to 0. The current flowing through the drive coil reaches the maximum, the eddy current induced on the projectile armature reaches the maximum, and the controllable switch is automatically turned off; within 0.28~0.45ms, the residual current of the drive coil forms a freewheeling circuit through the diod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com