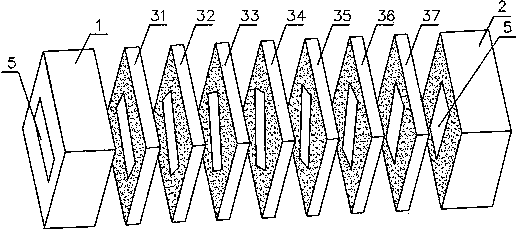

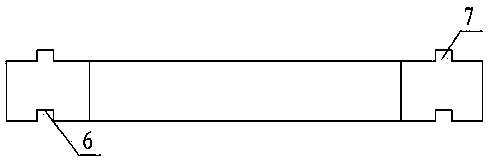

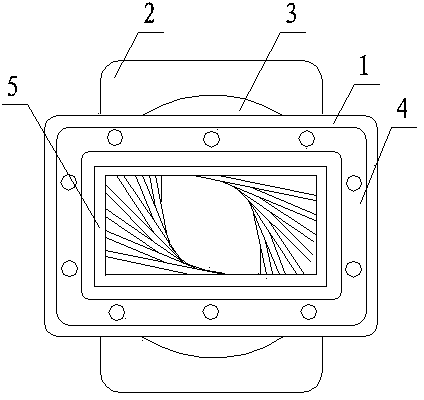

Self-positioning stepped twisted waveguide and vacuum brazing process thereof

A brazing process and self-positioning technology, which is applied to waveguides, waveguide-type devices, manufacturing tools, etc., can solve the problems of difficult control of the waveguide rotation angle, difficulty in ensuring the dimensional accuracy of parts, and high technical requirements for technicians, so as to ensure brightness and compactness , improve assembly accuracy, and overcome the effect of large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] [Embodiment 1] The self-positioning stepped twist waveguide vacuum brazing process comprises the following steps:

[0059] S1: Complete the machining of the cover plate, bottom plate and assembly plate according to the design;

[0060] S2: Surface treatment is carried out on the machined cover plate, bottom plate and assembly plate respectively;

[0061] S3: Make brazing material, make brazing material according to the outer dimensions of the cover plate, bottom plate and assembly plate, spread the prepared brazing material on the corresponding positions of the cover plate, bottom plate and assembly plate, and complete the cover plate, bottom plate and assembly plate assembly;

[0062] S4: Vacuum brazing, the assembled waveguide is put into the vacuum aluminum brazing furnace together with the fixture for vacuum brazing. The specific steps are:

[0063] S41: The vacuum aluminum brazing furnace performs the first rough vacuuming;

[0064] S42: Vacuum aluminum brazing ...

Embodiment 2

[0085] [Example 2] Self-positioning stepped twist waveguide vacuum brazing process, which includes the following steps:

[0086] S1: Complete the machining of the cover plate, bottom plate and assembly plate according to the design;

[0087] S2: Surface treatment is carried out on the machined cover plate, bottom plate and assembly plate respectively;

[0088] S3: Make brazing material, make brazing material according to the outer dimensions of the cover plate, bottom plate and assembly plate, spread the prepared brazing material on the corresponding positions of the cover plate, bottom plate and assembly plate, and complete the cover plate, bottom plate and assembly plate assembly;

[0089] S4: Vacuum brazing, the assembled waveguide is put into the vacuum aluminum brazing furnace together with the fixture for vacuum brazing. The specific steps are:

[0090] S41: The vacuum aluminum brazing furnace performs the first rough vacuuming;

[0091] S42: Vacuum aluminum brazing f...

Embodiment 3

[0112] [Embodiment 3] The self-positioning stepped twist waveguide vacuum brazing process comprises the following steps:

[0113] S1: Complete the machining of the cover plate, bottom plate and assembly plate according to the design;

[0114] S2: Surface treatment is carried out on the machined cover plate, bottom plate and assembly plate respectively;

[0115] S3: Make brazing material, make brazing material according to the outer dimensions of the cover plate, bottom plate and assembly plate, spread the prepared brazing material on the corresponding positions of the cover plate, bottom plate and assembly plate, and complete the cover plate, bottom plate and assembly plate assembly;

[0116] S4: Vacuum brazing, the assembled waveguide is put into the vacuum aluminum brazing furnace together with the fixture for vacuum brazing. The specific steps are:

[0117] S41: The vacuum aluminum brazing furnace performs the first rough vacuuming;

[0118] S42: Vacuum aluminum brazing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com