Glabridin micro-emulsion and preparation method thereof

A technology of glabridin and microemulsion, which is applied in pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., can solve the problems of low encapsulation rate, no significant, unstable state, etc., and achieve the effect of high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] (1) Take glabridin powder 10g at room temperature, put the glabridin powder in a beaker, add polyoxypropylene stearate 15g, and stir evenly; (2) add polyglycerol sebacate in the beaker again for 11g and 6g of Tween 85, continue to stir evenly; (3) finally add 12g of propylene glycol and 46g of deionized water, stir evenly; (4) use a vortex oscillator to vortex the mixture in the beaker until the solution changes from cloudy Stop after reaching a clear state, and prepare a glabridin microemulsion.

Embodiment 2

[0014] (1) Take glabridin powder 13g at room temperature, put the glabridin powder in a beaker, add polyoxypropylene stearate 10g, stir well; (2) add polyglycerol sebacate in the beaker again for 7g and Tween 85 to 7g, continue to stir evenly; (3) finally add 16g of propylene glycol and 47g of deionized water, stir evenly; (4) use a vortex oscillator to vortex the mixture in the beaker until the solution is turbid Stop after reaching a clear state, and prepare a glabridin microemulsion.

Embodiment 3

[0016] (1) Take glabridin powder 15g at room temperature, put the glabridin powder in a beaker, add polyoxypropylene stearate 12g, stir well; (2) add polyglycerol sebacate in the beaker again for 9g and Tween 85 to 9g, continue to stir evenly; (3) finally add 14g of propylene glycol and 41g of deionized water, stir evenly; (4) use a vortex oscillator to vortex the mixture in the beaker until the solution changes from cloudy Stop after reaching a clear state, and prepare a glabridin microemulsion.

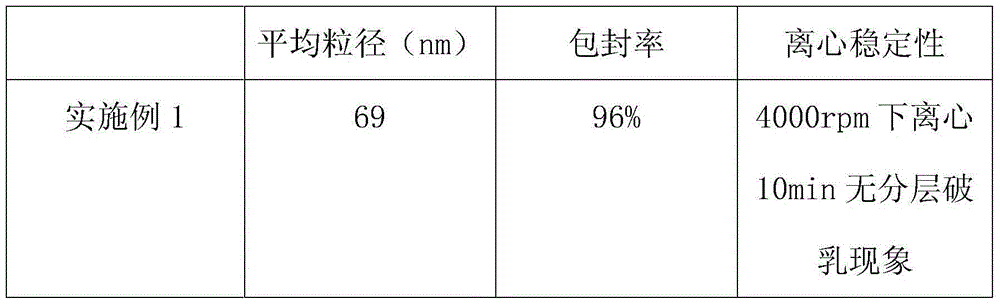

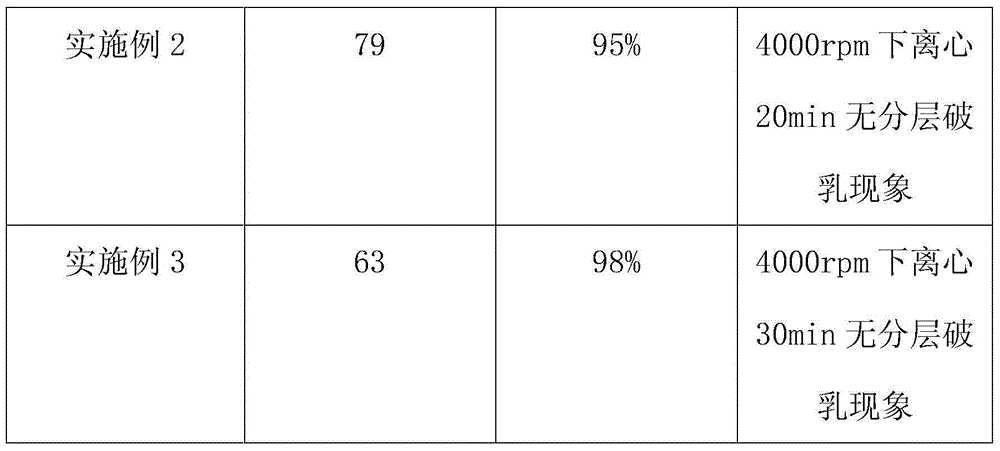

[0017] The particle size of the glabridin microemulsion prepared in Example 1, Example 2, and Example 3 was measured by a particle size analyzer, and the encapsulation efficiency and centrifugal stability were also measured.

[0018]

[0019]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com