Device for cutting products on three sides

A product, cutting technology used in transportation and packaging, positioning objects, metal processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

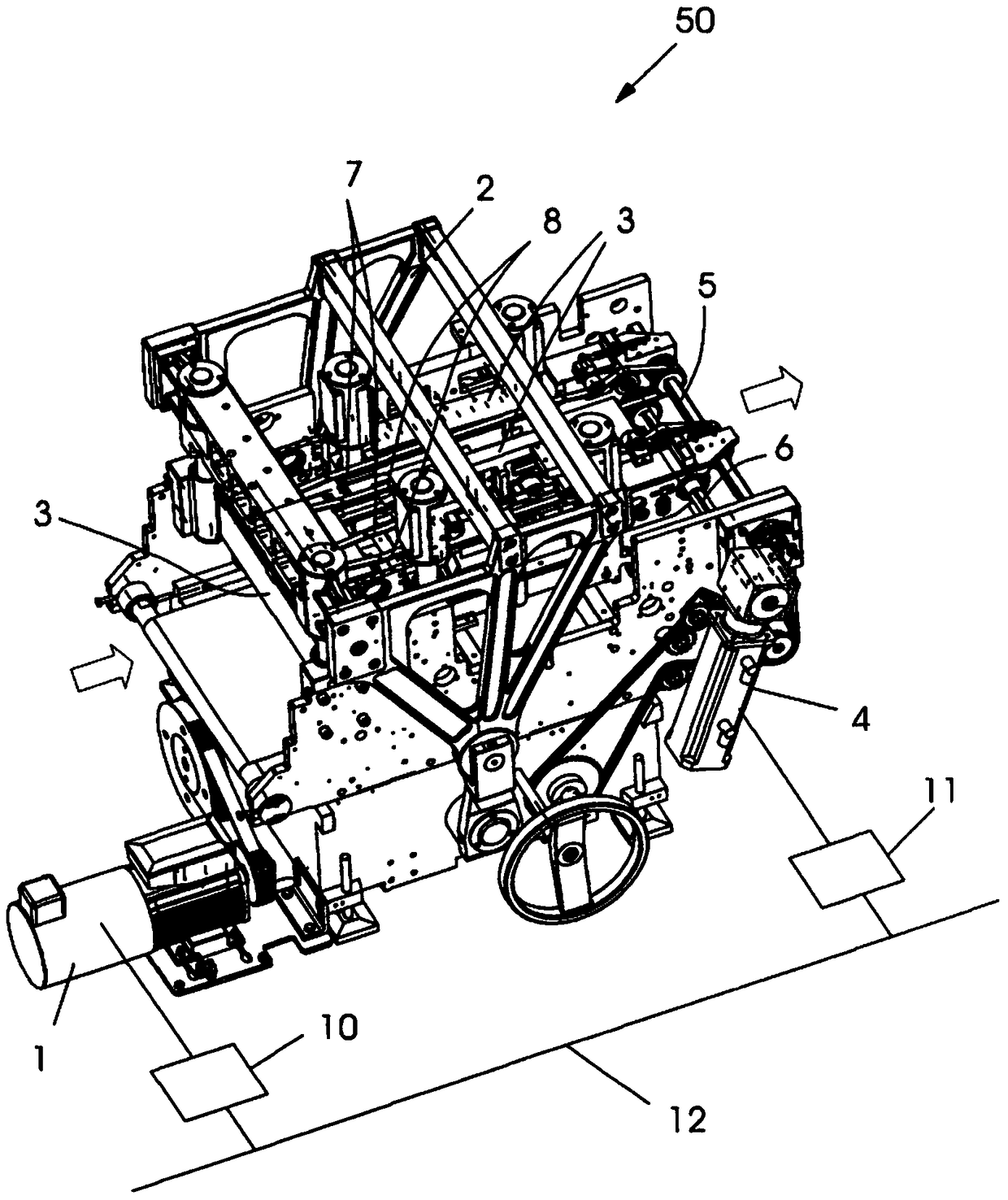

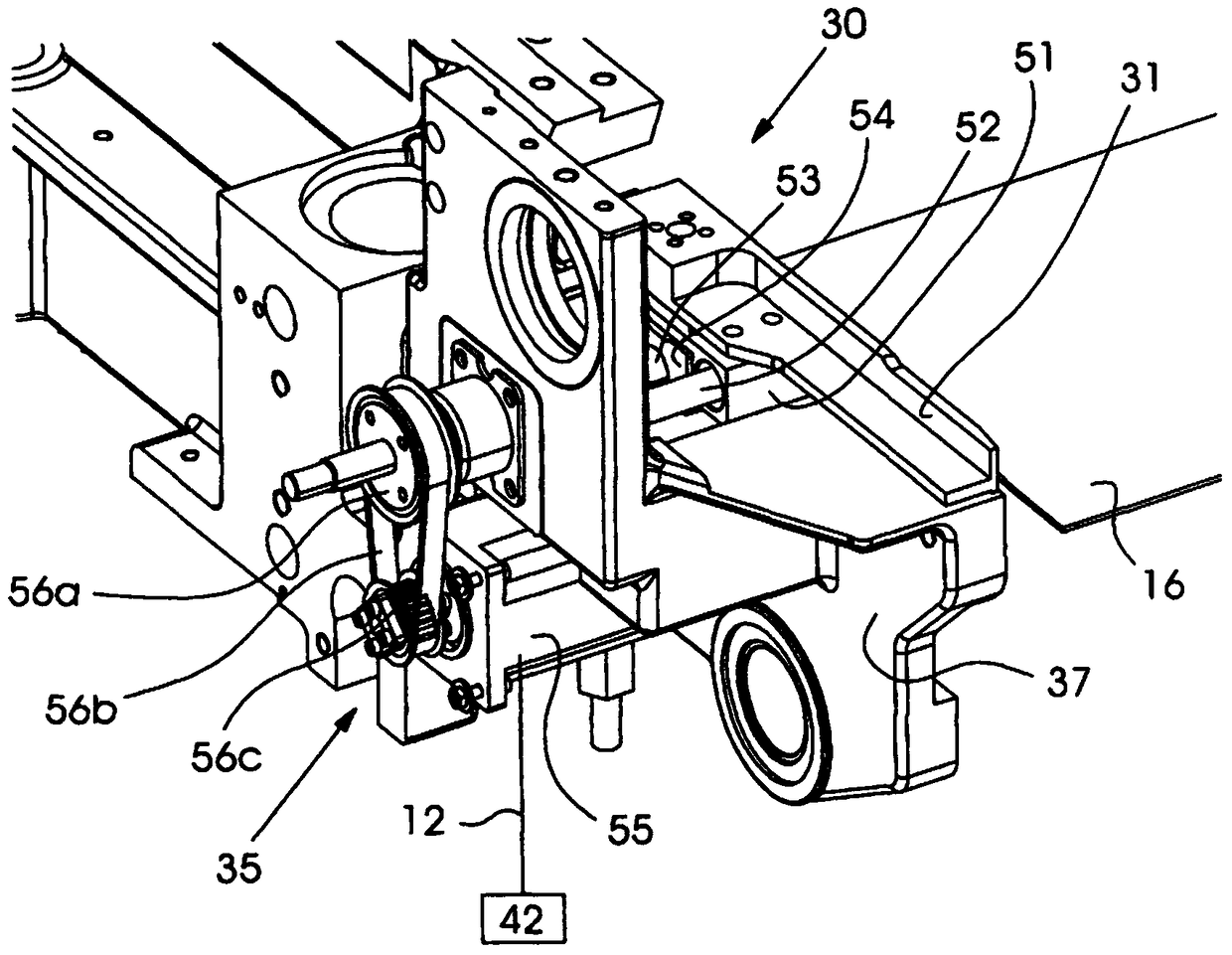

[0018] figure 1 A representative example of an apparatus for trimming products on three sides is shown. The first drive motor 1 moves the tool movement device 2 on which the tool 3 is fastened. The direction of product movement is indicated by arrows. The second drive motor 4 drives the conveyor belts 7 , 8 of the conveyor device 9 via the first and the second drive shaft 5 , 6 . Control units 10 , 11 are provided for the two drive motors 1 , 4 , which can communicate with each other via a data and / or control signal exchange link 12 . Furthermore, the connection 12 also leads to a machine control unit and to an alignment control mechanism 42 of the alignment device 30 .

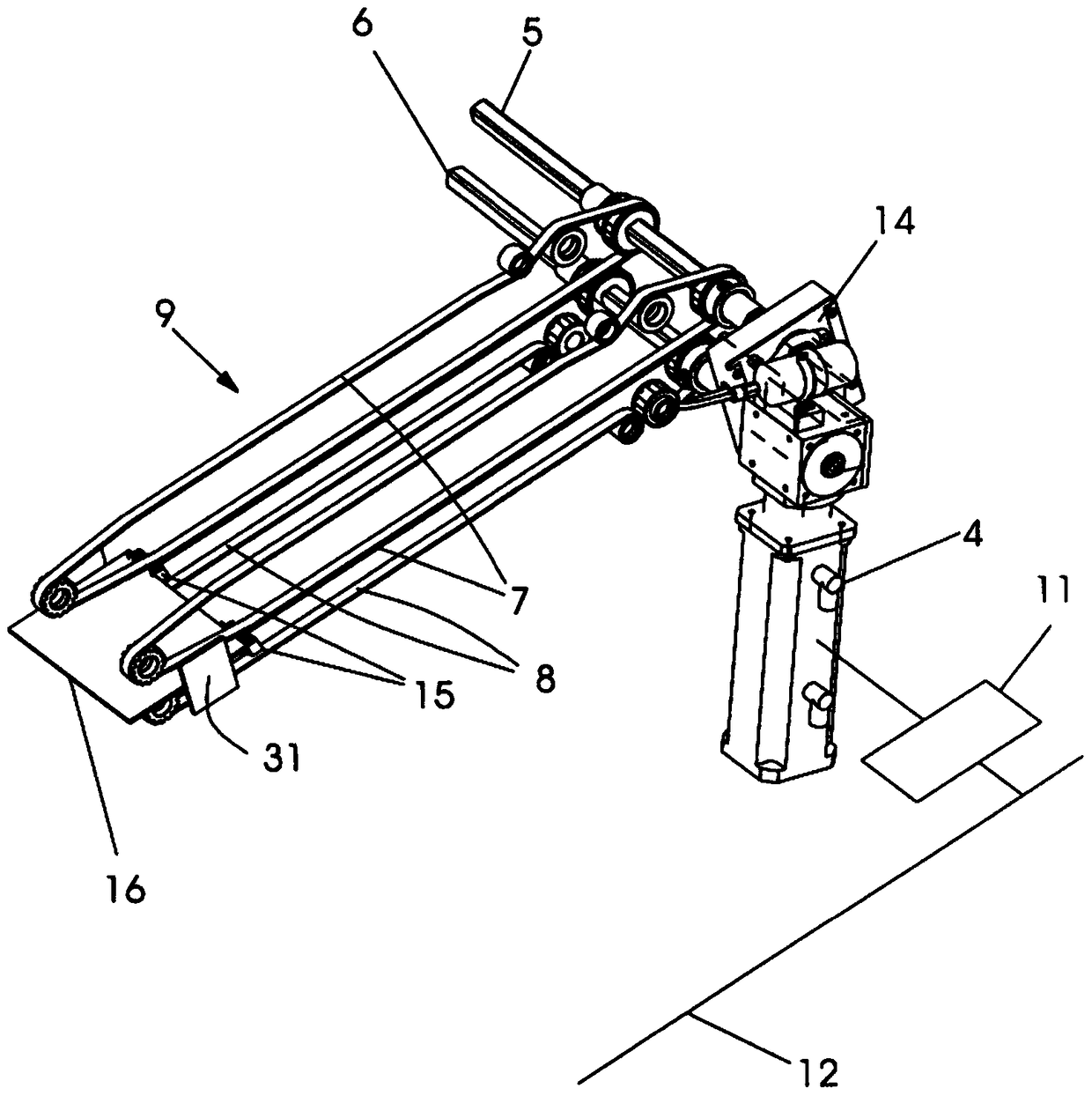

[0019] figure 2 The delivery device itself is shown. The drive motor 4 drives the drive shafts 5 , 6 and the conveyor belts 7 , 8 of the conveyor system by means of a mechanical transmission 14 . Furthermore, a control unit 11 and a data and / or control signal exchange connection 12 can be seen. Produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com