Automatic iron core welding equipment

A welding equipment and iron core technology, applied in the field of iron core welding, can solve the problems of far-reaching overall mechanization, low work efficiency, manual operation, etc., and achieve the effect of reducing manpower burden, high pass rate, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Attached below Figure 1~8 The technical scheme in the embodiment of the present invention is described:

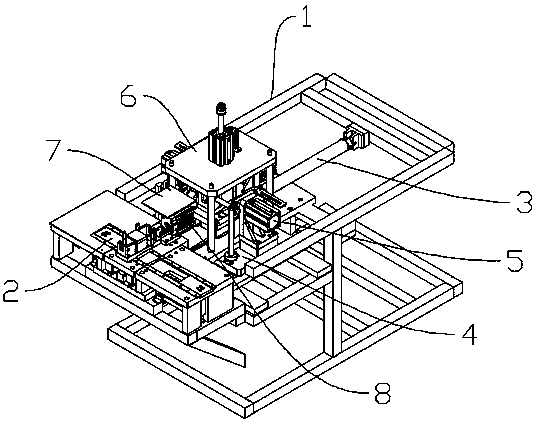

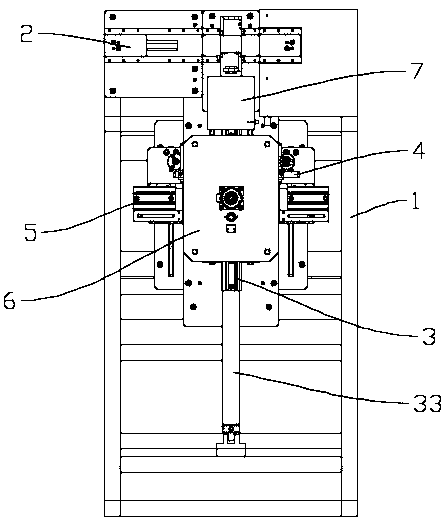

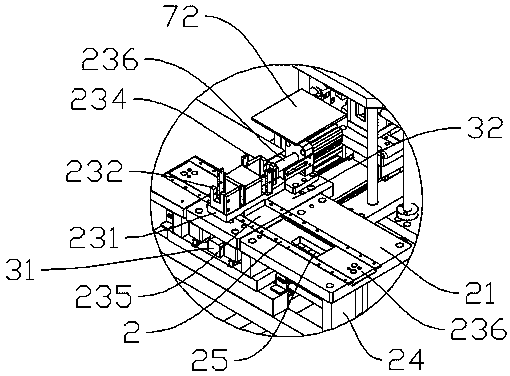

[0030] Such as figure 1 As shown, the present invention provides an automatic iron core welding equipment, including a workbench 1, a clamping mechanism 2, a feeding mechanism 3 and a welding mechanism 4, and the clamping mechanism 2, the feeding mechanism 3 and the welding mechanism 4 are all arranged on the working On the platform 1, the clamping mechanism 2 is arranged on the feeding mechanism 3, and the welding mechanism 4 cooperates with the clamping mechanism 2.

[0031] Such as Figure 1~8 In order to improve the safety performance during welding, a protective cover 7 is provided on the workbench 1, and the heat generated by welding, waste gas or welding slag is isolated from the direct contact with the human body by using the protective cover 7 to ensure welding safety. The side is provided with an opening 71 for the feeding table 32 to pass through. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com