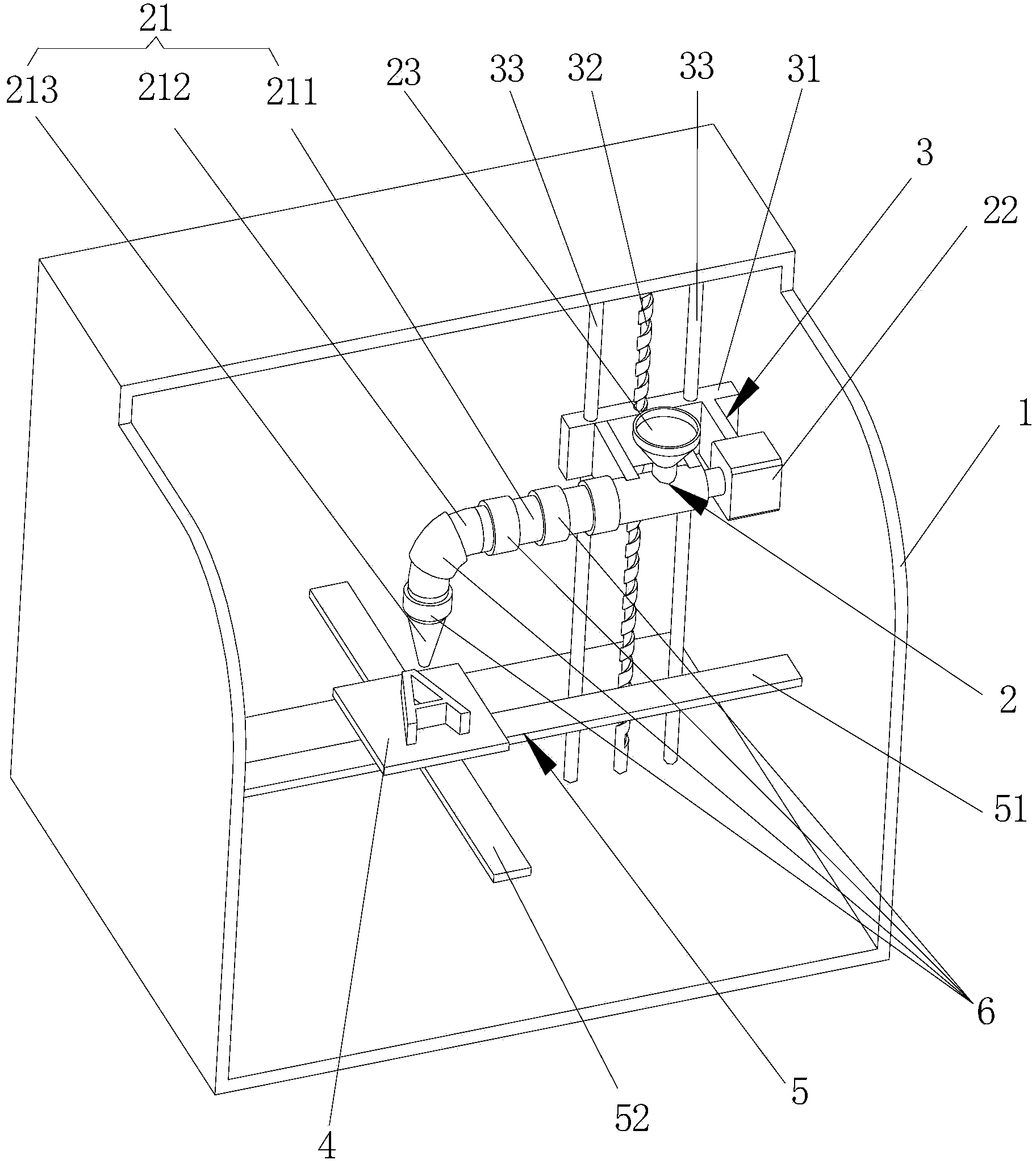

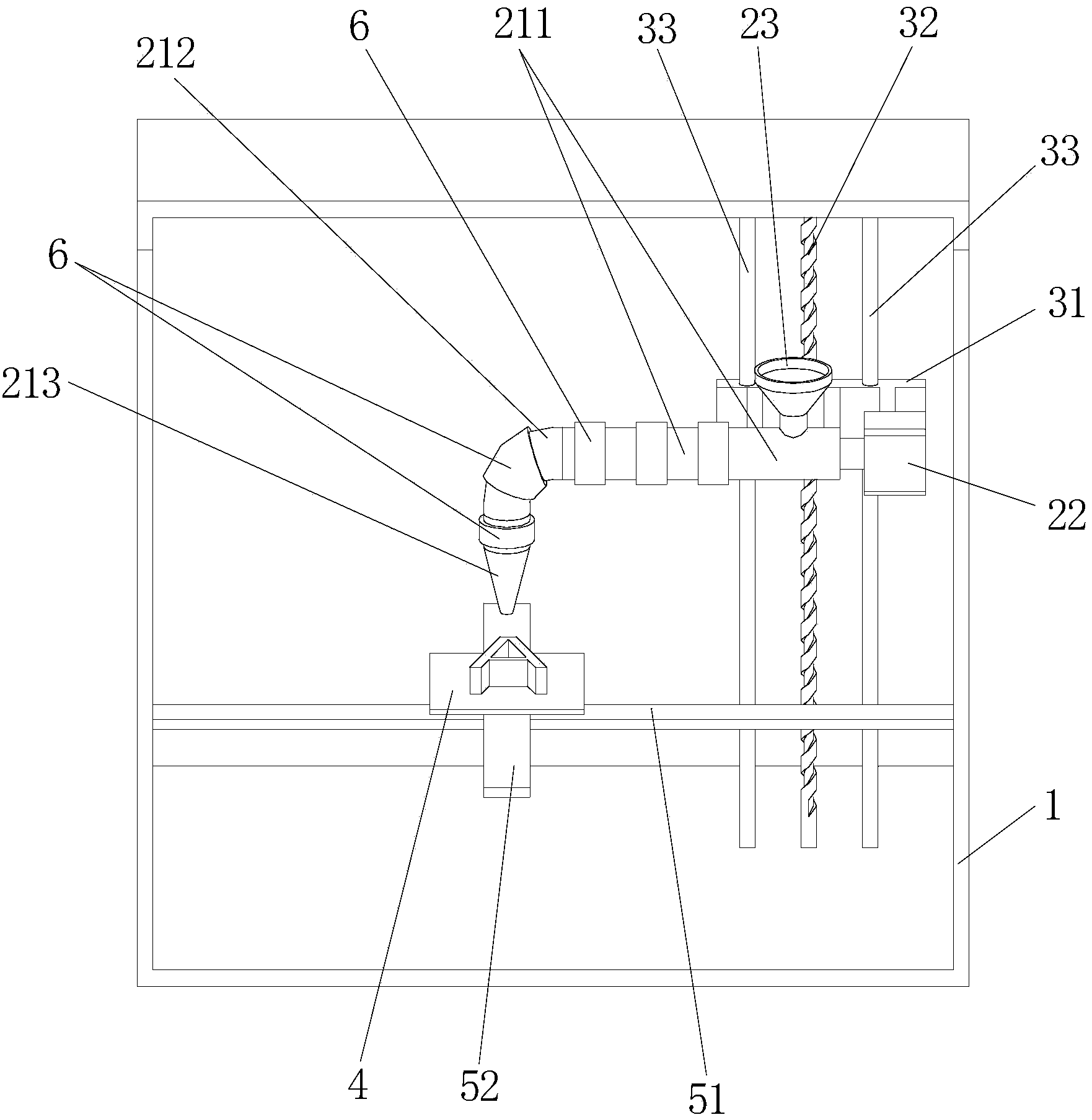

3D (Three-Dimensional) printer based on rotation and continuous extrusion of threaded rod

A 3D printer and screw technology, which is applied in the field of 3D printers based on screw rotation and continuous extrusion, can solve the problems of poor printing effect, unstable extrusion material, poor continuity, etc., and achieve the effect of improving printing quality and good rotation speed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

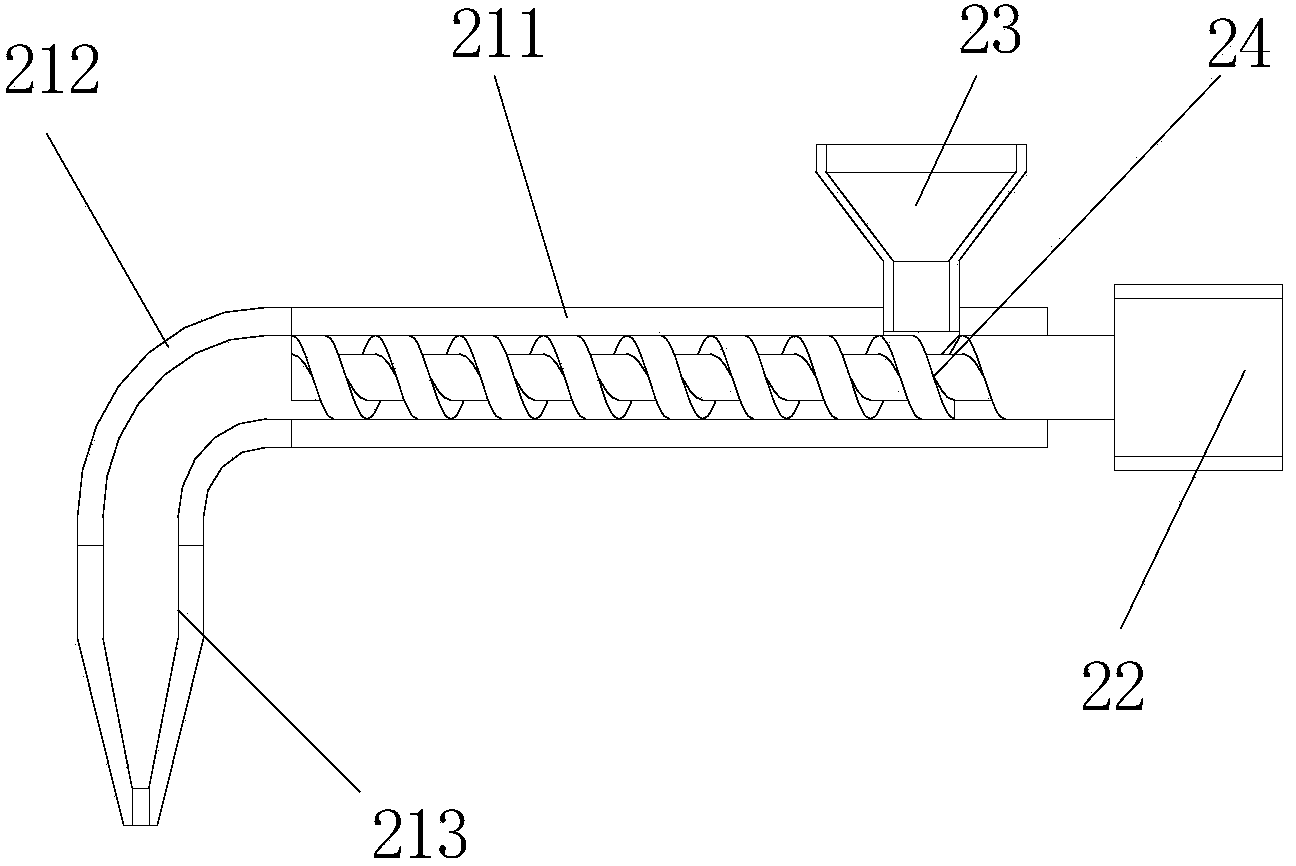

Embodiment 2

[0037] This 3D printer based on screw rotation and continuous extrusion is the same as Embodiment 1 except for the following technical features: in order to make the printing materials more fully mixed and transported more stably, the number of the screws 24 is 2, and the 2 screws 24 are specifically: A driving screw 241 and a driven screw 242 , one end of the driving screw 241 is connected to the rotating shaft of the motor 22 , and the driving screw 241 and the driven screw 242 are engaged. When performing a printing job, start the motor 22 to drive the driving screw 241 to rotate, and the driven screw 242 meshing with the driving screw 241 will be driven to rotate together, so that the printing materials can be mixed evenly and the printing materials will be transported from the conveying part to the transition section.

[0038] In this embodiment, a twin-screw mechanism is adopted to make the printing materials more fully mixed and transported more stably, thereby further ...

Embodiment 3

[0040] This 3D printer based on screw rotation and continuous extrusion is the same as Embodiment 1 except for the following technical features: for better and faster printing, there are two sets of extrusion mechanism 2 and lifting mechanism 3, and the two sets of The extrusion mechanism 2 is symmetrically installed in the housing 1 through two sets of lifting mechanisms 3 respectively. Adopt double extrusion mechanism 2, which can process two different types of materials or two different colors of materials at the same time, so as to further meet the specific needs of users.

Embodiment 4

[0042] This 3D printer based on screw rotation and continuous extrusion is the same as Embodiment 2 except for the following technical features: for better and faster printing, there are two sets of extrusion mechanism 2 and lifting mechanism 3, and the two sets of The extrusion mechanism 2 is symmetrically installed in the housing 1 through two sets of lifting mechanisms 3 respectively. Adopt double extrusion mechanism 2, which can process two different types of materials or two different colors of materials at the same time, so as to further meet the specific needs of users. At the same time, in order to make the printing materials mix more evenly, this embodiment also adopts a twin-screw mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com