Carbon fiber bicycle rim with good radiating performance and bicycle

A technology of heat dissipation performance and bicycle, which is applied to wheels, wheels, vehicle parts and other directions made of non-metallic materials. To achieve the effect of reducing heat accumulation and heating, good heat dissipation performance, and avoiding temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

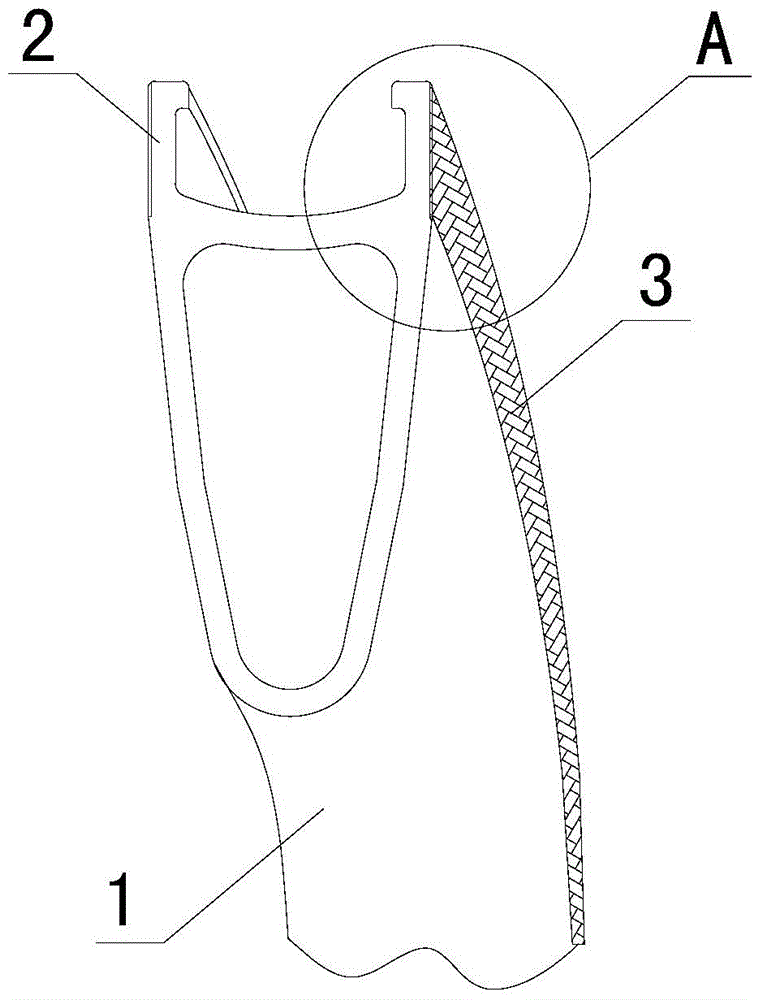

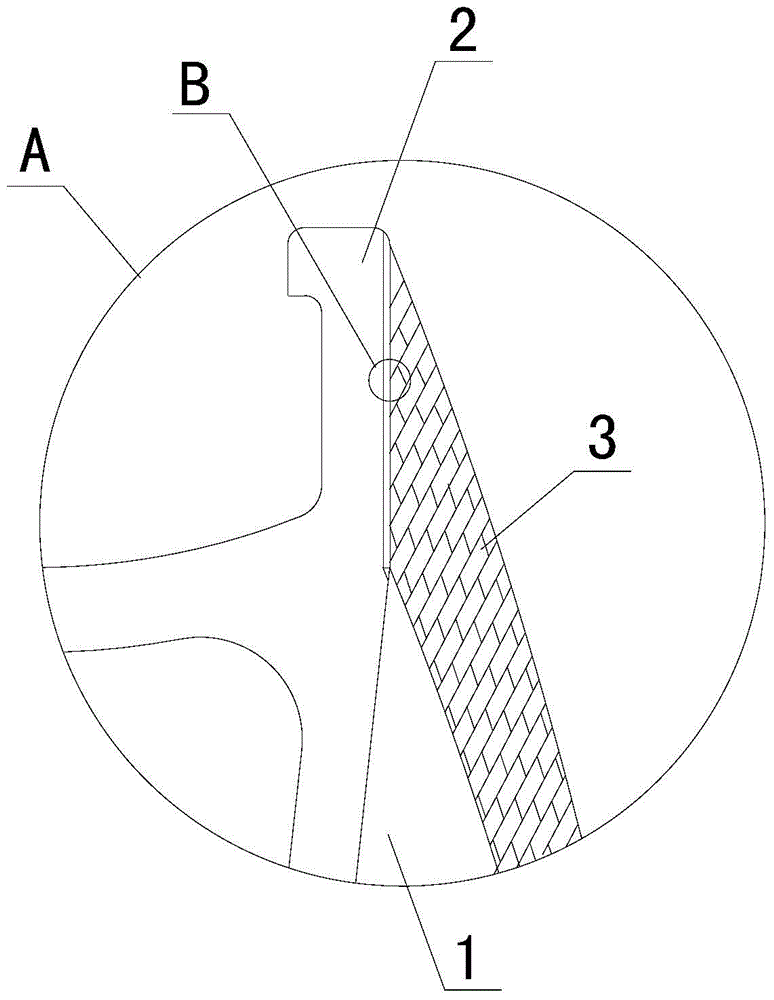

[0029] Such as Figure 1-Figure 3 Shown: a carbon fiber bicycle rim with good heat dissipation performance, including a rim body 1, and brake sides 2 arranged on both sides of the rim body 1, the outer surface of the brake side 2 is provided with a reinforcement layer 3, the reinforcement layer 3 Woven from fiberglass with metal coating.

[0030] The structure, material, manufacturing method, etc. of the rim body 1 can adopt the prior art. In this embodiment, the rim body 1 is made of carbon fiber. The structure and size of the braking edge 2 are all prior art, and the structure and size of the prior art can be adopted.

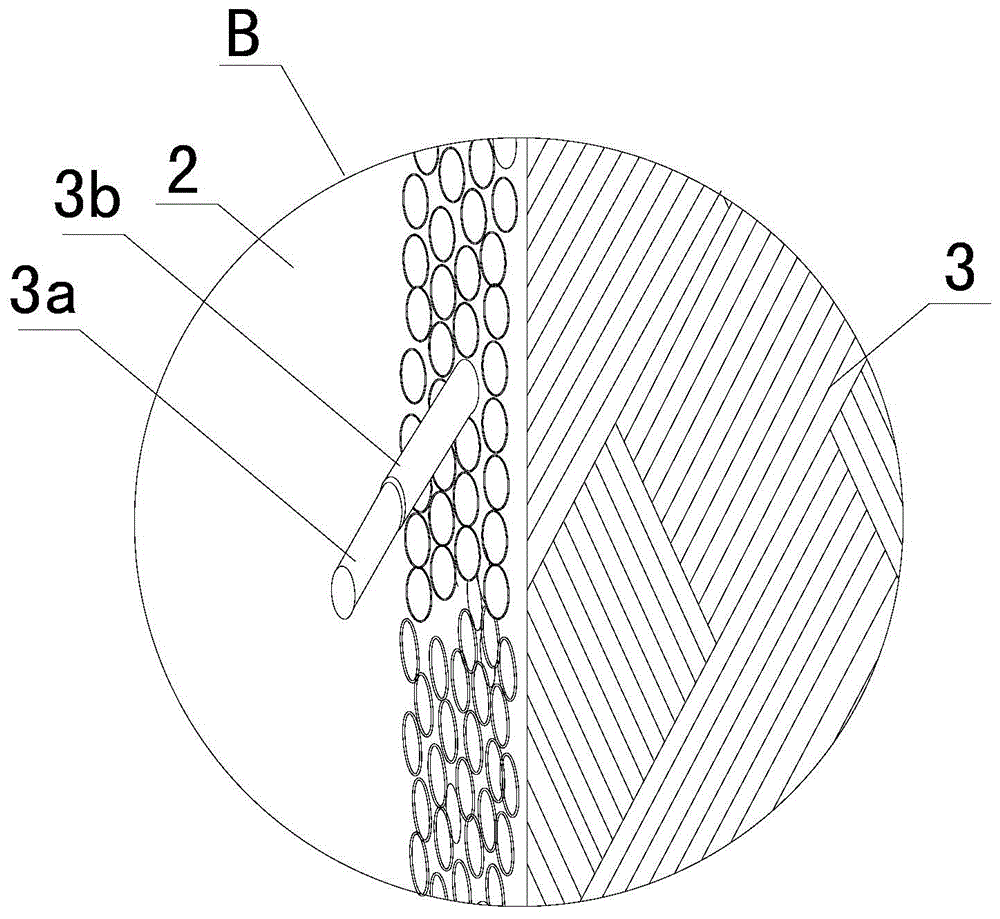

[0031] Such as image 3 As shown, the reinforcement layer 3 is made of glass fibers with metal coating in plain weave or twill weave. The thickness of the reinforcement layer is generally 0.03-0.5mm, including glass fibers 3a and metal coatings 3b coated on the outer wall of the glass fibers 3a. . The diameter of the glass fiber is generally 3-100 μm; th...

Embodiment 2

[0036] A bicycle, the bicycle rim adopts the carbon fiber bicycle rim disclosed in Embodiment 1 with good heat dissipation performance. The bicycle is a racing bicycle or a mountain bike, and other structures of the bicycle can adopt the structures of the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com