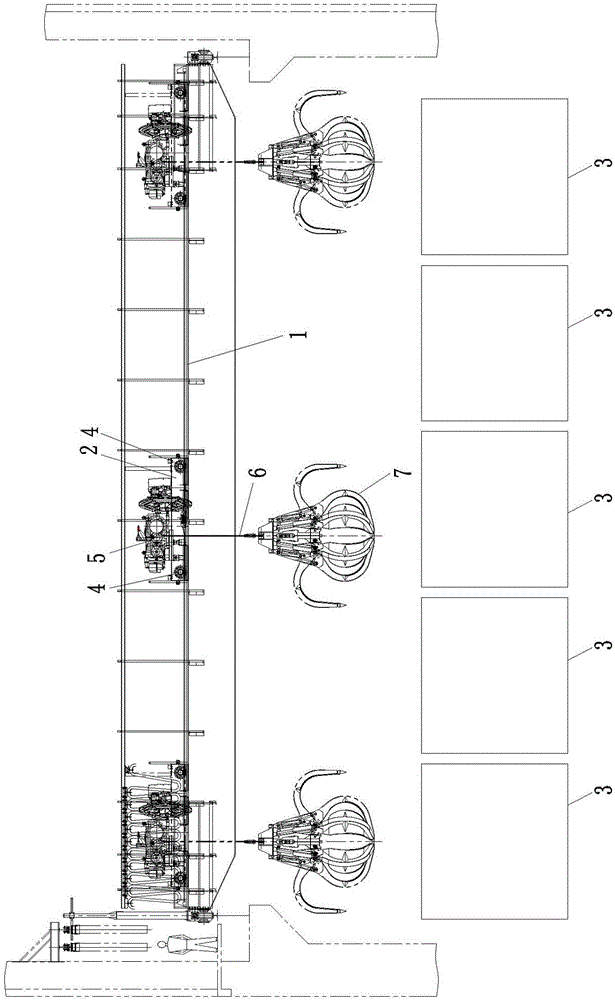

Bridge grabbing crane of trolley chain wheel positioning system with absolute value encoder

An absolute encoder, bridge crane technology, applied in the direction of trolley crane, crane, transportation and packaging, can solve problems such as aggravating computing tasks, data loss, etc., to reduce workload, improve data reliability, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

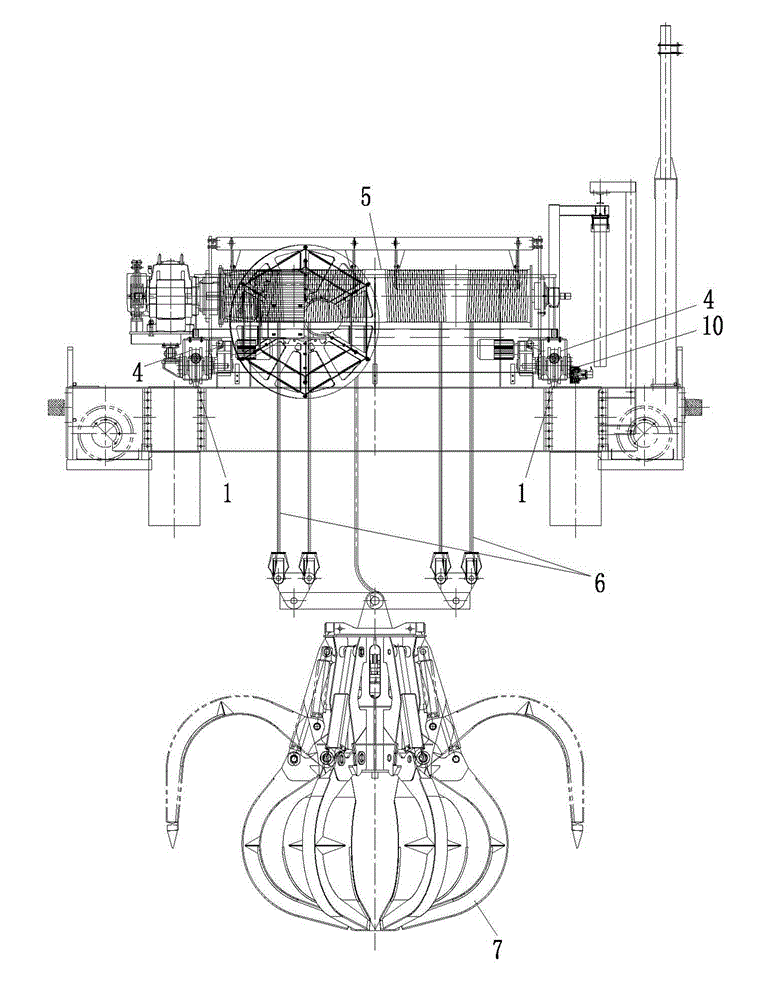

[0038] The sprocket case 10 on both sides of the sprocket 13 is symmetrically installed with two tensioning wheels 16, and the two tensioning wheels 16 are tensioned and connected with the chain 14 at the same time.

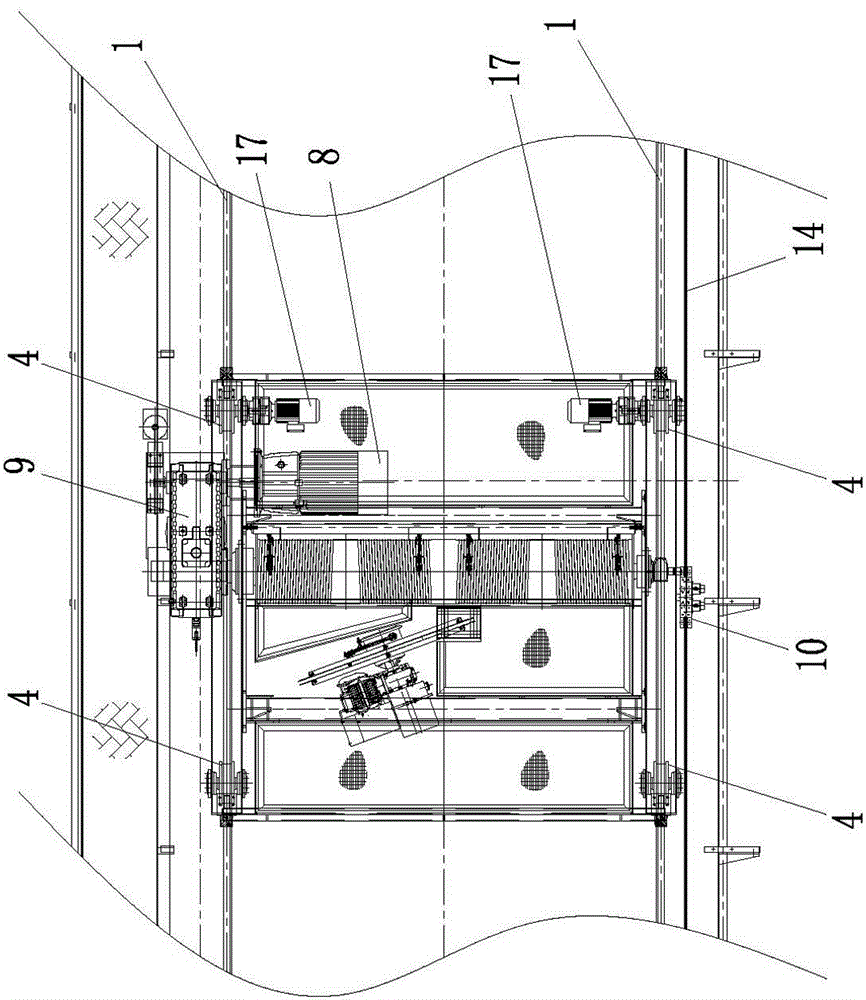

[0039] A trolley motor 17 for driving the trolley wheel 4 is installed on the crane trolley 2, so that the crane trolley 2 moves on the guide rail 1, and the trolley motor 17 is electrically connected with the control device.

[0040] The absolute encoder 15 is provided with an encoder shaft 1501, and the encoder shaft 1501 is connected to one end of the sprocket shaft.

[0041] The absolute encoder 15 is installed on one side of the sprocket case 10 through an encoder bracket 18 .

[0042] The control device includes PLC and frequency converter.

[0043] The control device also includes a touch screen, a PROFIBUS-DP bus communication card and a frequency converter, the PROFIBUS-DP bus communication card is installed in the frequency converter card slot, the mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com