Rapid dewatering and curing method for sludge

A technology of rapid dehydration and solidification method, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of difficult real-time control and adjustment of pharmaceuticals and output, and failure to achieve accurate real-time control of pharmaceutical additions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0045] The sludge rapid dehydration and solidification system in the present invention collects the original mud, adds preset amounts of solidifying agent and dehydrating agent to a continuous pipeline, and outputs them after mixing. The whole dehydration and solidification process is realized continuously.

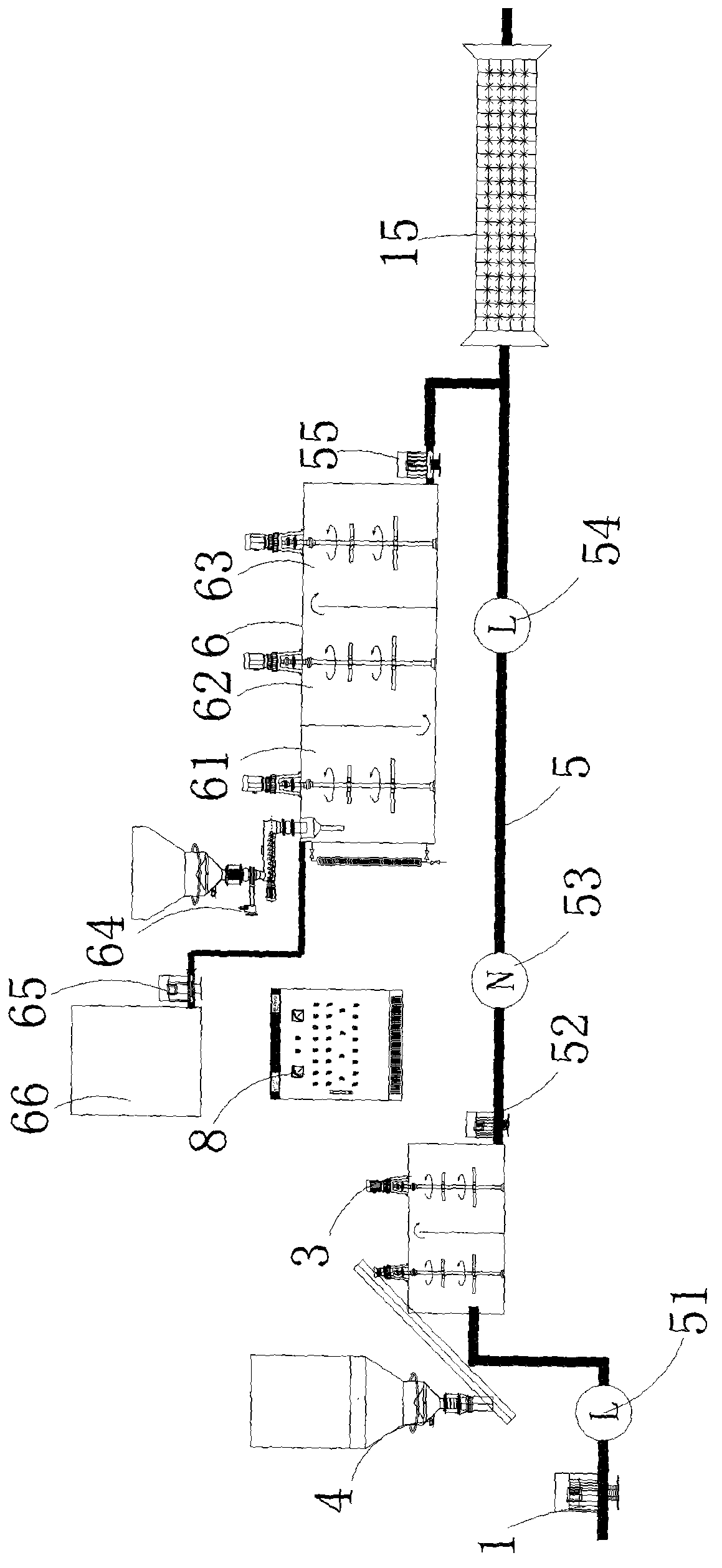

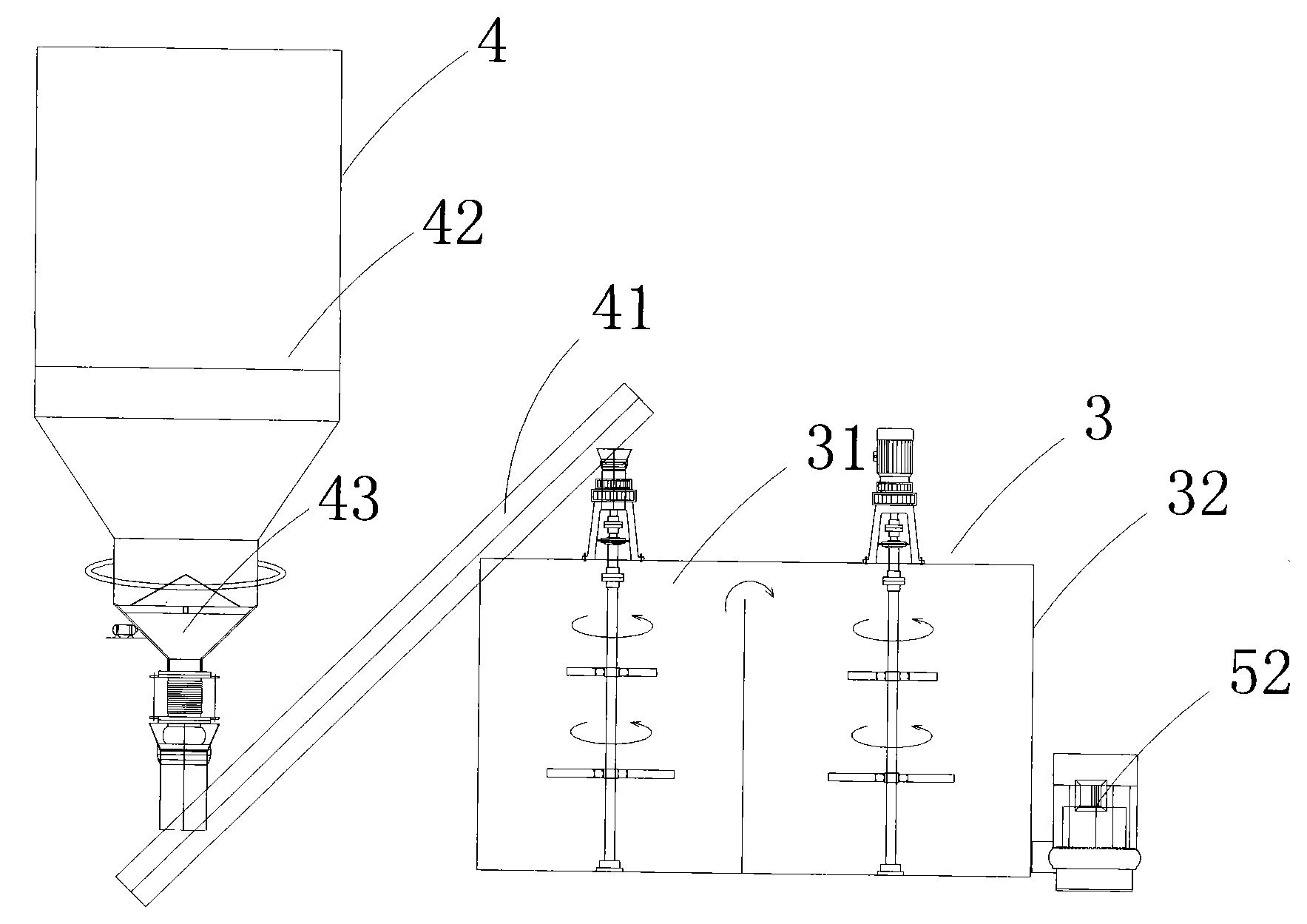

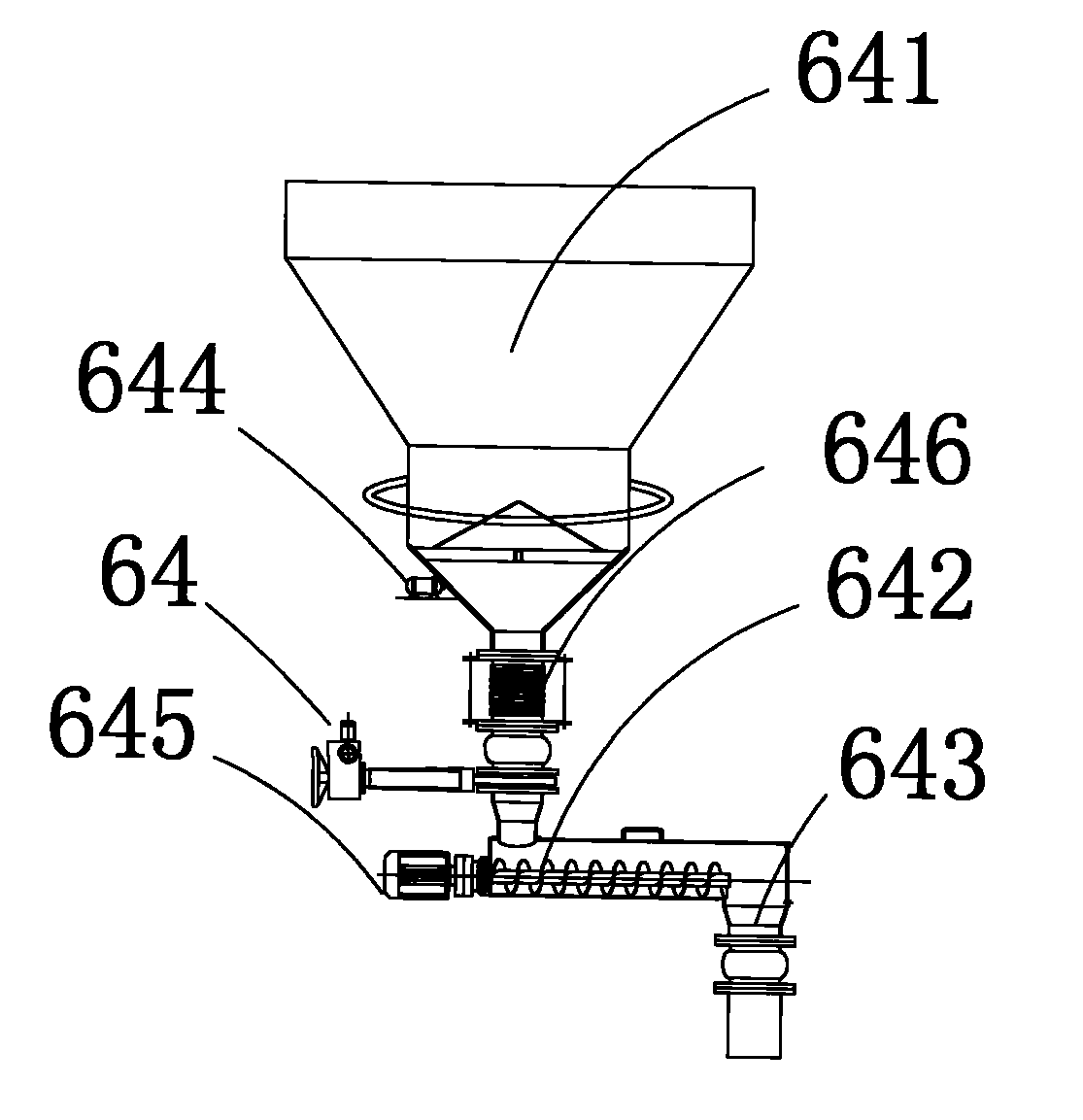

[0046] see figure 1 As shown, it is a schematic diagram of the overall structure of the sludge rapid dehydration solidification system of the present invention, the system includes a slurry pump 1, a coagulant mixing device 3, a dehydrating agent mixing device 6, a control device and a pipeline 5 , wherein, the slurry extraction mud pump 1 is used to extract natural mud, the flow rate of the first mud pump 1 is determined according to the performance of the overall equipment, and it is input into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com