Synthesis method of chloridized-2,3,5-triphenyl tetrazolium chloride

A technology of triphenyltetrazolium and synthesis method, applied in the direction of organic chemistry, etc., to achieve the effects of increased yield, easy source of raw materials, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

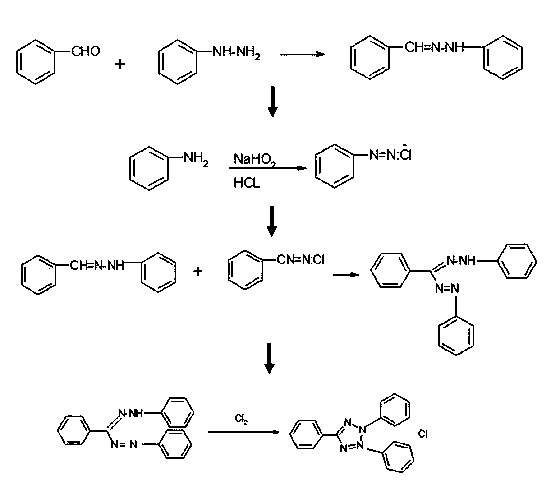

Method used

Image

Examples

Embodiment 1

[0024] (4) Synthesis of 2,3,5-triphenyltetrazolium chloride: put the 2,3,5-triphenylformazan obtained in step (3) into a 100ml three-necked flask, and then add 60ml of methanol , turn on the stirring device, cool down to below 0°C with an ice bath, and slowly introduce Cl into the solution 2 The gas is saturated, the reaction process is obviously exothermic, and the Cl is controlled to 2 Speed, the temperature during the reaction should not exceed 15°C. With Cl 2 The feeding of the flask, the black crystals suspended in the flask gradually decreased, and the solution gradually turned brown, and when the solution was clear and free of suspended solids, stop passing Cl 2 , the reaction was stirred at room temperature for 2 h. After the reaction was completed, the solvent was evaporated under reduced pressure to obtain 6.1 g of a yellow-brown crude product with a yield of 61%. The solid was refluxed with chloroform, decolorized with activated carbon, filtered with suction, th...

Embodiment 2

[0030] (4) Synthesis of 2,3,5-triphenyltetrazolium chloride: put the 2,3,5-triphenylformazan obtained in step (3) into a 250ml three-necked flask, and then add 100ml of methanol , turn on the stirring device, cool down to below 0°C with an ice bath, and slowly introduce Cl into the solution 2 The gas is saturated, the reaction process is obviously exothermic, and the Cl is controlled to 2 Speed, the temperature during the reaction should not exceed 15°C. With Cl 2 The feeding of the flask, the black crystals suspended in the flask gradually decreased, and the solution gradually turned brown, and when the solution was clear and free of suspended solids, stop passing Cl 2 , the reaction was stirred at room temperature for 2 h. After the reaction was completed, the solvent was evaporated under reduced pressure to obtain 12.6 g of a yellow-brown crude product with a yield of 63%. The solid was refluxed with chloroform, decolorized with activated carbon, filtered with suction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com