Roller washing machine with detachable inner barrel

A drum washing machine and inner tub technology, which is applied to washing machines with containers, other washing machines, washing devices, etc., can solve the problems of secondary pollution of laundry, contamination of the drum wall, retention of dirt and bacteria, etc. The effect of pollution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

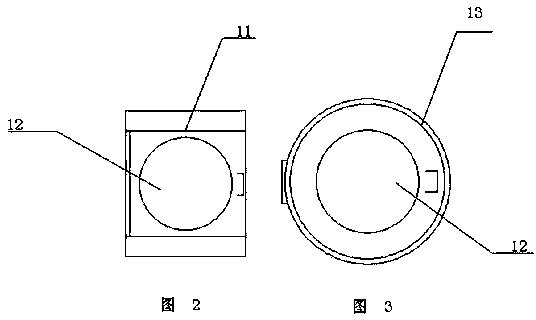

[0020] In Embodiment 2, the transmission shaft 7 adopts a square shaft, and the bottom flange of the inner barrel 2 is provided with a square groove matching the square shaft, and the square shaft and the square groove are connected and cooperated to form an axial fixing device. When the inner barrel 2 needs to be cleaned, the square shaft can be unloaded.

Embodiment 3

[0021] In Embodiment 3, the transmission shaft 7 is a triangular shaft, and the bottom flange of the inner barrel 2 is provided with a triangular groove matching the triangular shaft, and the triangular shaft and the triangular groove are connected and cooperated to form an axial fixing device. When the inner tub 2 needs to be cleaned, the triangular shaft can be unloaded.

Embodiment 4

[0022] In Embodiment 4, splines are arranged on the transmission shaft, and the electromagnet 9 can also be designed into other shapes to replace the splines.

[0023] Working process of the present invention

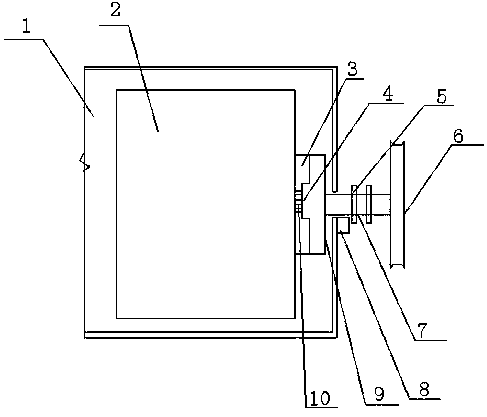

[0024] A magnetizer 3 is fixed on the bottom flange of the inner tub of the washing machine, and an electromagnet 9 is fixed on the transmission mechanism. When the washing machine is in operation, the electromagnet 9 is energized to generate magnetism. In terms of mechanism, the mutual mechanical transmission and center positioning of the electromagnet 9 and the magnetizer 3 (inner tub and transmission mechanism) are also coordinated accordingly. When the washing machine is washing and rinsing, the inner tub and the transmission mechanism run synchronously, and will not be affected by the buoyancy of the washing liquid and the inner tub. The shaking of 2 breaks away from the transmission mechanism. During dehydration, the inner tub 2 and the transmission mechanism run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com