Integral open-excavation node top-down underground engineering construction method

A technology for node inversion and underground engineering, applied in water conservancy projects, infrastructure engineering, artificial islands, etc., can solve the problems of inconvenient excavation and feeding, large amount of demolition, and difficult construction, to ensure waterproof quality, convenient and fast construction. , the effect of reliable technical measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

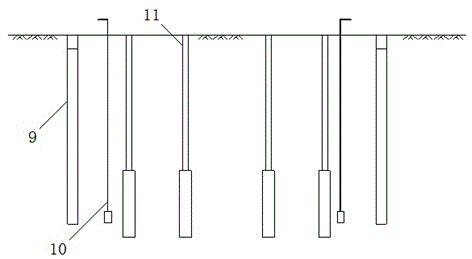

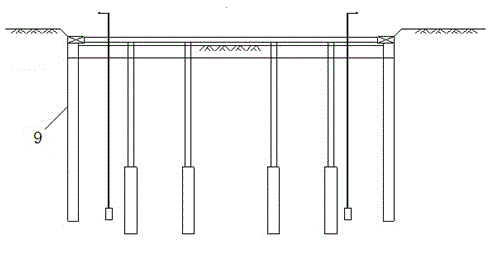

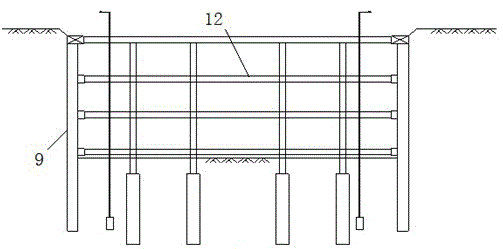

[0042] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings.

[0043] Figure 1 to Figure 9 It is a schematic diagram of the construction method of the overall open-cut joint inversion of the present invention. Take the construction of the second-story underground structure and the setting of four supports in the foundation pit as an example to illustrate, and the rest of the underground engineering is similar to the description of this construction method. Such as Figure 1 to Figure 9 As shown, the underground engineering construction method of integral cut-and-cut node reverse of the present invention comprises the following steps:

[0044] 1. According to the construction system of the open cut method, the foundation pit enclosure structure, temporary column piles and temporary columns are constructed, and the dewatering well is constructed to dewater to 0.5m below the excavation surface; the foundation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com