Split type high silicon-iron alloy acid-proof axial flow pump

A ferroalloy, shell-type technology, applied in non-variable pumps, non-volume pumps, pumps for special fluids, etc., can solve high temperature resistance, poor corrosion resistance, unsafe installation, and poor solid abrasion resistance and other problems, to achieve the effect of strong corrosion resistance, good solid abrasion resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

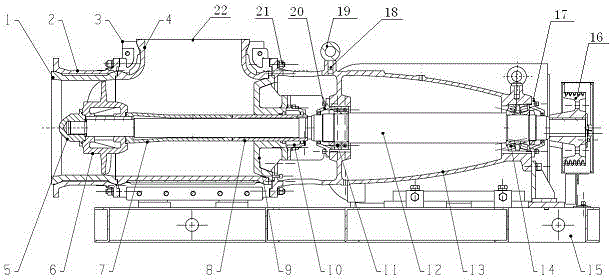

[0009] Embodiment, referring to the accompanying drawings, a shell-type high-silicon-iron alloy acid-resistant axial-flow pump includes a shaft 12, and a transmission wheel 16 is fixed at the right end of the shaft 12. It is characterized in that the shaft 12 is installed in the front bearing 11 and the rear bearing 14, and the front The bearing 11 and the rear bearing 14 are contained in the bearing box 13; the rear bearing cover 17 is fixed with bolts on the right end of the rear bearing 14, and the front bearing cover 20 is installed on the left end of the front bearing 11; the sealing shaft sleeve 8 is installed on the left end of the shaft 12, The left side of the sealing shaft sleeve 8 is equipped with a sheath 7, and the left side of the sheath 7 is equipped with an impeller 6, and the left side of the impeller 6 is threaded with the left end of the shaft 12 with the impeller nut 5; An extension sleeve 2 is installed on the outside of section 1, and the extension sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com