High-temperature-resistant reinforced corrugated expansion joint

A corrugated tube and reinforced technology, which is applied to the expansion compensation device, heat preservation, and pipe components used in the pipeline, can solve the problems of short service life of the compensator, influence on the flow diversion effect, and the fall of the diversion tube, etc., so as to prolong the service life Life, improve service life, ensure the effect of diversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

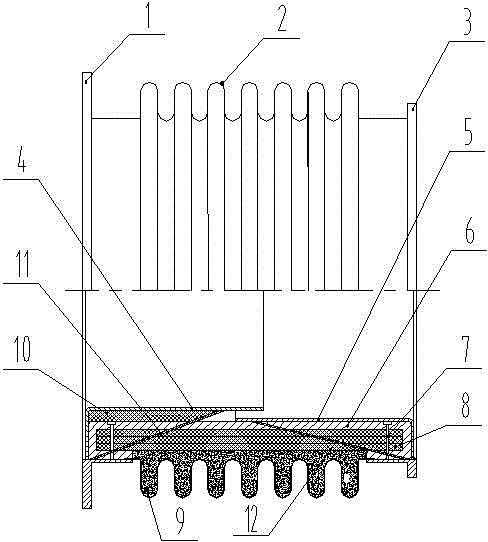

[0020] The high temperature resistant reinforced bellows compensator shown in the attached figure includes left flange 1, bellows 2, right flange 3, left guide tube 4, right guide tube 5, first support rod 11 and second support rod 12. The left guide tube 4 and the right guide tube 5 are sleeve structures with flange sides, and their outward flange sides are respectively welded to the inner walls of the left flange 1 and right flange 3, and the other ends are right guide tubes. Part of the flow tube 5 is coaxially fitted on the left guide tube 4; one end of the first support rod 11 is fixedly connected to the inner wall of the left flange 1, and the other end is fixedly connected to the outer wall of the left guide tube 4; one end of the second support rod 12 is fixed Connected to the inner wall of the right flange 3, and the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com