transformer

A transformer and winding technology, applied in the field of transformers, can solve the problems of short axial winding length, many radial winding layers, and many radial layers, etc., and achieve good anti-saturation ability, short winding circumference, and reduce effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

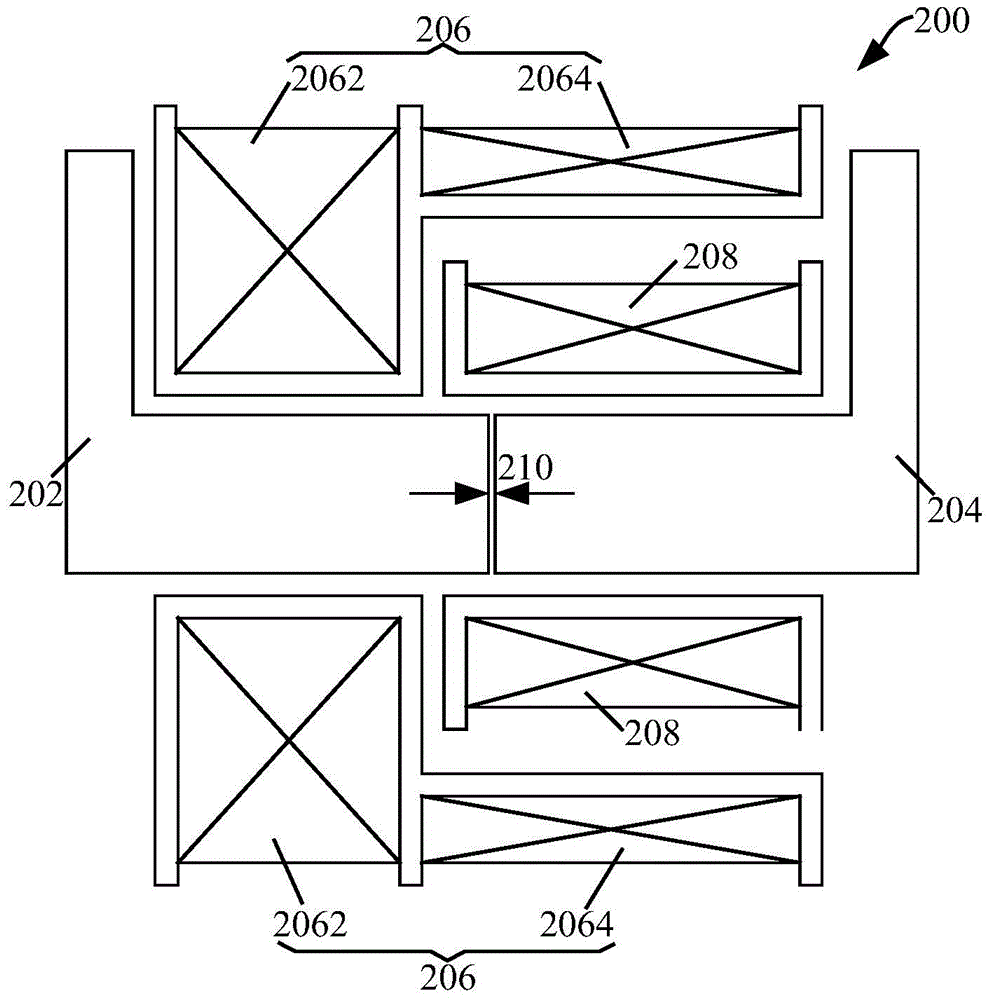

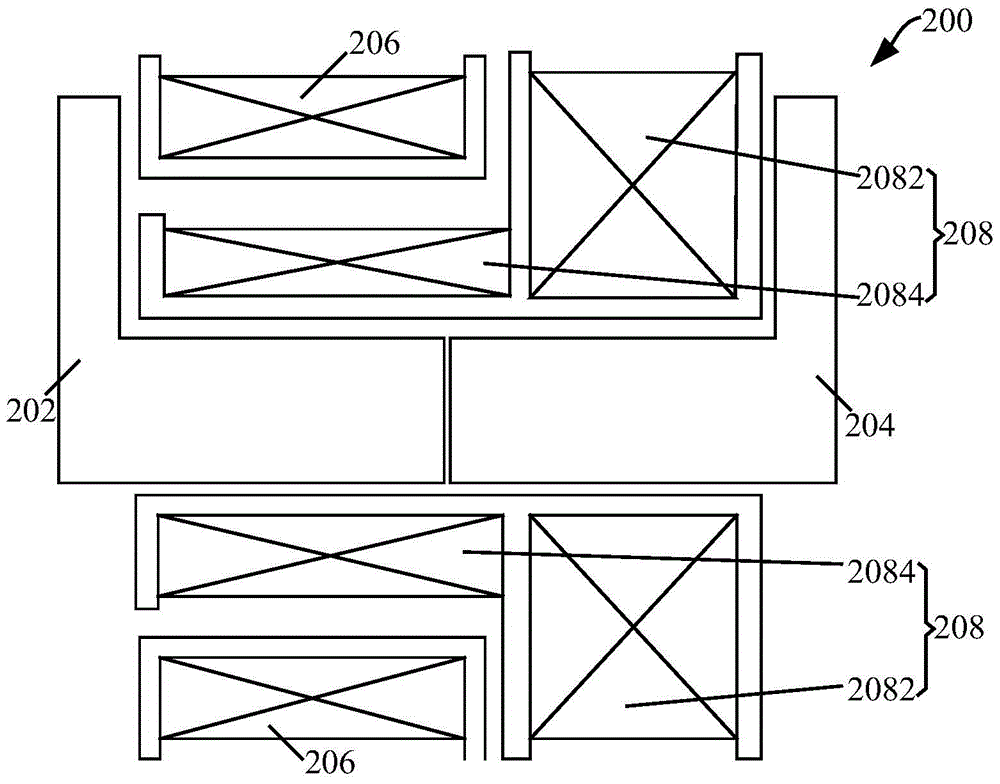

[0052] Such as Figure 3A As shown, the two magnetic cores include two L-shaped magnetic cores, that is, an L-shaped magnetic core 202 and an L-shaped magnetic core 204 , wherein one end of the L-shaped magnetic core 202 and one end of the L-shaped magnetic core 204 are placed opposite to each other.

Embodiment approach 2

[0054] Such as Figure 3B As shown, the two cores include an L-shaped core 302 and an I-shaped core 304 .

Embodiment approach 3

[0056] Such as Figure 3C As shown, the two cores include two T-shaped cores, T-shaped core 306 and T-shaped core 308 .

[0057] Certainly, when the closed magnetic core assembly is composed of a plurality of magnetic cores, there are also various implementations. Below, on the basis of the above-mentioned open magnetic core assembly, three structures of the closed magnetic core assembly are listed below.

[0058] Implementation Mode 1

[0059] Such as Figure 4A shown in Figure 3A On the basis of the open-circuit magnetic core assembly shown, another magnetic core 402 is added to form a closed magnetic core assembly with the L-shaped magnetic core 202 and the L-shaped magnetic core 204 .

[0060] Implementation mode two

[0061] Such as Figure 4B shown in Figure 3B On the basis of the open-circuit magnetic core assembly shown, another magnetic core 404 is added to form a closed magnetic core assembly with the L-shaped magnetic core 302 and the I-shaped magnetic core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com