Magnetic ring partition winding piece

A magnetic ring and wire winding technology, which is applied in the manufacture of coils, etc., can solve the problems of not being able to ensure that the winding wires are evenly spaced, arranged neatly and partitioned symmetrically, easily affected by human factors, and affecting the related parameters of the magnetic ring, etc., so as to shorten the manual process. Winding time, low production cost, uniform winding density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

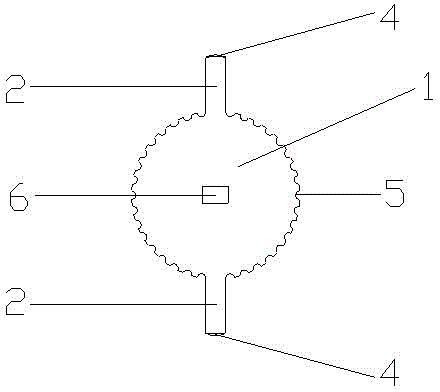

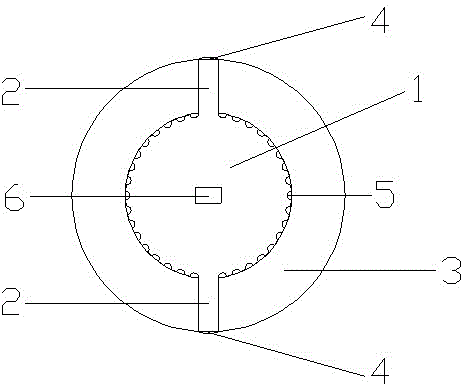

[0028] Example 1, such as figure 1 and figure 2 As shown, a magnetic ring partitioned wire winding part includes a circular plate 1 and a partition part 2, the diameter of the circular plate 1 is equal to the diameter of the inner ring of the magnetic ring 3; the partition part 2 is set to two , respectively arranged at both ends of the diameter of the circular plate 1, one end of the partition part 2 is connected to one end of the circular plate 1, and the other end of the partition part 2 is provided with a The card edge 4 on the ring surface, the length of the partition part 2 is the difference between the radius of the outer ring of the magnetic ring 3 and the radius of the inner ring, and the card edge 4 passes through the silica gel layer arranged on the card edge and the surface of the outer ring of the magnetic ring 3 Tight engagement; Grooves 5 are arranged on the outer peripheral surface of the circular plate 1, the grooves 5 are evenly distributed on the outer per...

Embodiment 2

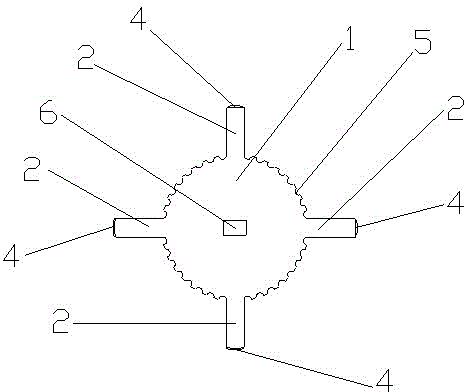

[0029] Example 2, such as image 3 and Figure 4 As shown, the only difference from Embodiment 1 is that the partitions 2 are set to four, which are evenly distributed on the side ends of the circular plate, so as to realize four equal partitions of the magnetic ring.

[0030] Compared with the prior art, the beneficial effect of the present invention is that without changing any structure of the magnetic ring 3 itself, but increasing the magnetic ring partition winding parts as winding auxiliary tools, through the magnetic ring partition winding parts The circular plate 1 and the partition part 2 are used to realize reasonable and effective partitioning and effective operation of winding. The grooves 5 are evenly distributed to ensure that the winding is orderly and tidy; The surfaces of the outer rings of the magnetic ring 3 are tightly engaged to make it more firm and reliable; the hollow handle 6 is convenient for installation and removal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com