A kind of preparation method of supercapacitor electrode material

A technology for supercapacitors and electrode materials, applied in the direction of hybrid capacitor electrodes, etc., can solve problems such as low energy density, poor cycle performance and power density, and achieve excellent rate performance, easy large-scale application, simple and effective methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Dissolve 0.166g terephthalic acid in 5 ml DMF;

[0019] 2) Dissolve 0.3565g nickel chloride hexahydrate in 10 ml H 2 O middle;

[0020] 3) Add the solution described in step 2) dropwise to the solution described in step 1);

[0021] 4) Put the solution described in step 3) into the reactor, and react at 120°C for 12 hours;

[0022] 5) The product obtained in step 4) was washed three times with water and ethanol respectively, and dried at 70°C for 24 hours to obtain a sample;

[0023] 6) This nickel-based metal-organic framework is made into a supercapacitor electrode.

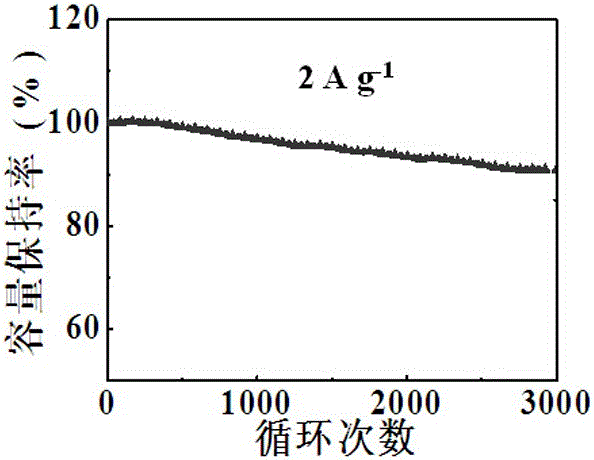

[0024] The maximum specific capacity of the nickel-based metal-organic framework electrode prepared in this example can reach 1127 F g -1 , after 3000 cycles, the capacity retention rate is 91%.

Embodiment 2

[0026] 1) Dissolve 0.166g terephthalic acid in 5 ml DMF;

[0027] 2) Dissolve 0.3565g nickel chloride hexahydrate in 10 ml H 2 O middle;

[0028] 3) Add the solution described in step 2) dropwise to the solution described in step 1);

[0029] 4) Put the solution described in step 3) into the reactor, and react at 100°C for 24 hours;

[0030] 5) The product obtained in step 4) was washed three times with water and ethanol respectively, and dried at 70°C for 24 hours to obtain a sample;

[0031] 6) This nickel-based metal-organic framework is made into a supercapacitor electrode.

[0032] The maximum specific capacity of the nickel-based metal-organic framework electrode prepared in this example can reach 1125 F g -1 , after 3000 cycles, the capacity retention rate is 90%.

Embodiment 3

[0034] 1) Dissolve 0.166g terephthalic acid in 5 ml DMF;

[0035] 2) Dissolve 0.3565g nickel chloride hexahydrate in 10 ml H 2 O middle;

[0036] 3) Add the solution described in step 2) to the solution described in step 1 dropwise;

[0037] 4) Put the solution described in step 3) into the reactor, and react at 130°C for 4 hours;

[0038] 5) The product obtained in step 4) was washed three times with water and ethanol respectively, and dried at 70°C for 24 hours to obtain a sample;

[0039] 6) This nickel-based metal-organic framework is made into a supercapacitor electrode.

[0040] The maximum specific capacity of the nickel-based metal-organic framework electrode prepared in this example can reach 1126 F g -1 , after 3000 cycles, the capacity retention rate is 90.3%.

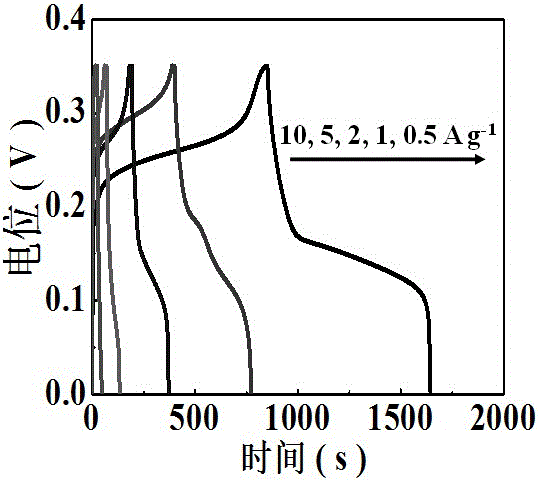

[0041] figure 1 The charge-discharge curves of Ni-MOF electrodes at different current densities. From figure 1 It can be calculated that the Ni-MOF electrode is at 0.5 A·g -1 , the specific capacity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com