System and method for compensating for high-frequency leakage currents in a motor vehicle

A technology for motor vehicles and leakage current, which is applied in the direction of motor vehicles, electric vehicle charging technology, electric vehicles, etc., and can solve the problems of increasing size and increasing vehicle weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

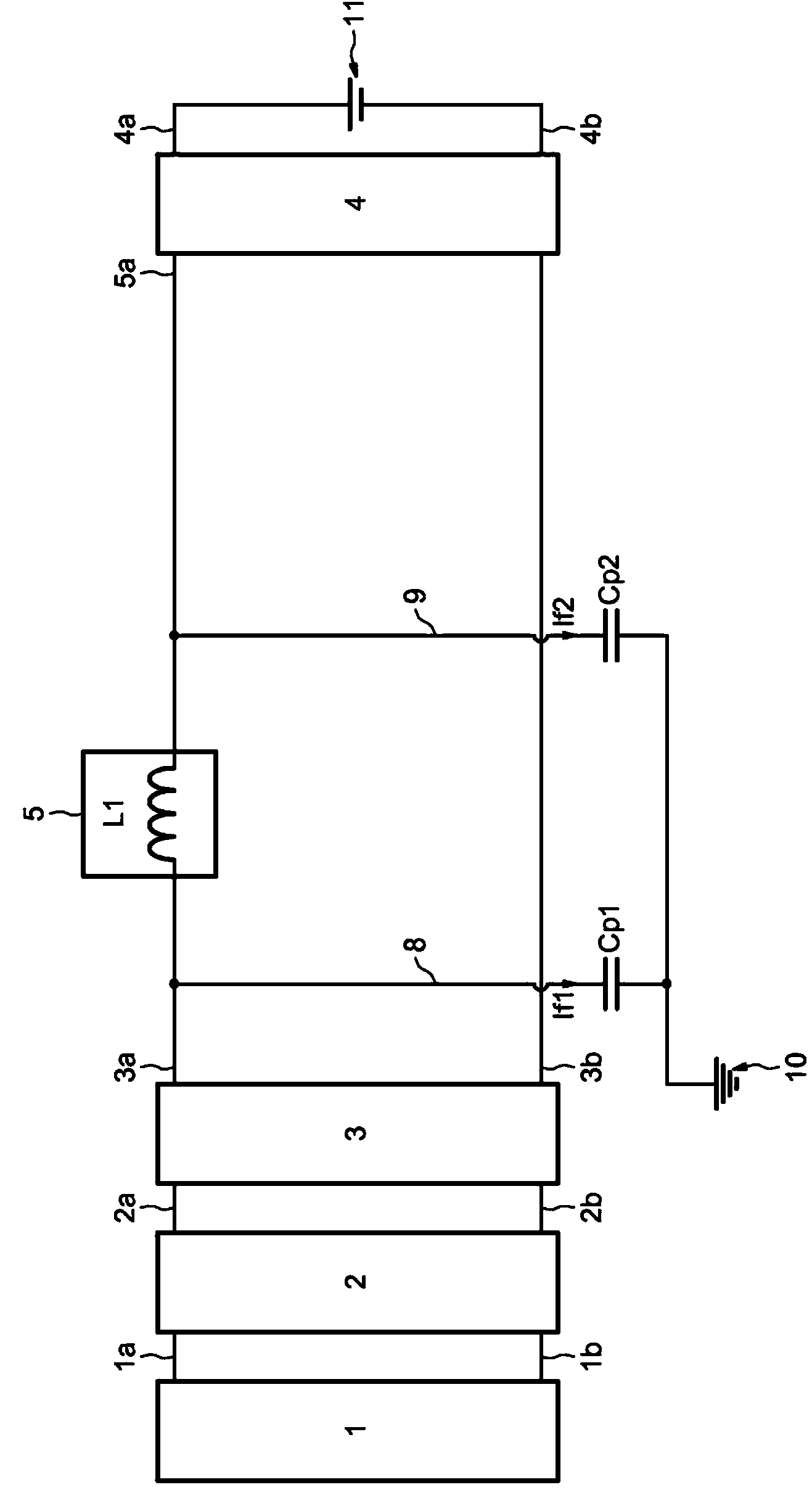

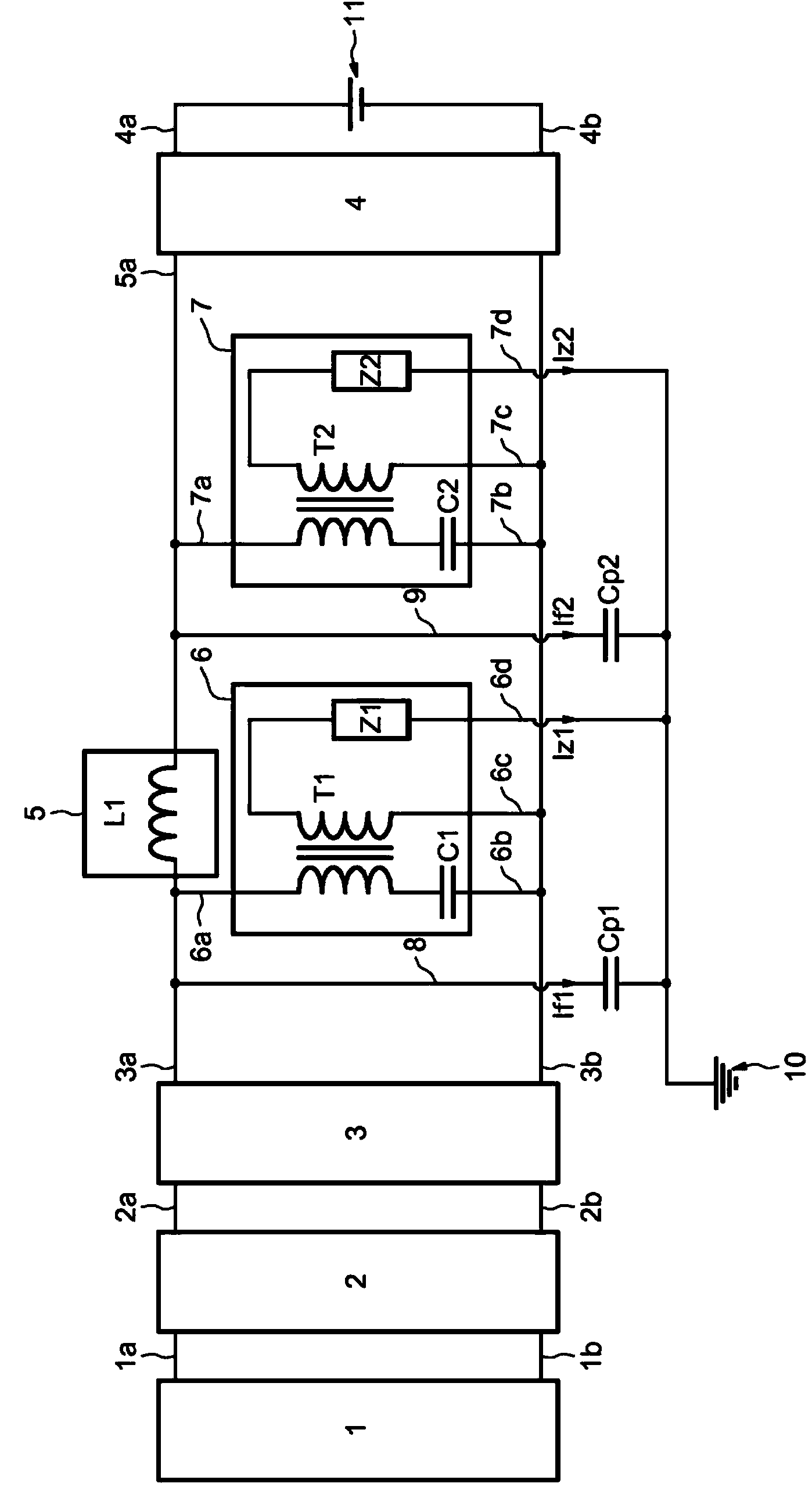

[0017] figure 1 A single-phase power supply network 1 is shown comprising a phase different from the ground pole linked to one connector 1a and a ground pole linked to one connector 1b.

[0018] The power supply network 1 is linked to the input of a common mode filter 2 via connectors 1a, 1b. The common mode filter 2 is linked at the output via a positive connector 2a and a negative connector 2b to a rectifier 3 which itself is linked at the output to an electric motor 5 via a connector 3a and via a The connector 3 b is linked to the inverter 4 . The rectifying device 3 may include a plurality of chopper switches. Connector 3a can carry high-frequency chopping voltage, thereby generating leakage currents If1 and If2.

[0019] An electric motor 5 is linked at the output to the other input of the inverter 4 via a connector 5a. The inverter 4 is also linked to a battery 11 via connectors 4a, 4b.

[0020] Connectors 1a, 2a, 1b and 2b carry a current originating from the phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com