Method for contactless measurement of relative positions by means of Hall sensors

A relative position, non-contact technology, applied in the field of displacement sensor, can solve the problems of error, unwanted change, insensitive signal processing operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

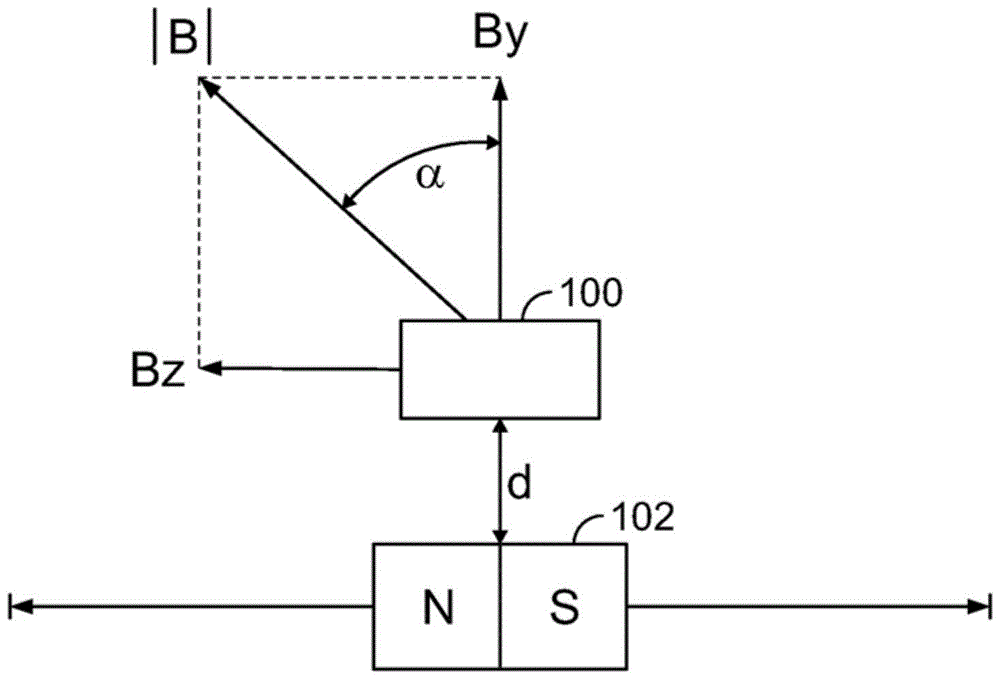

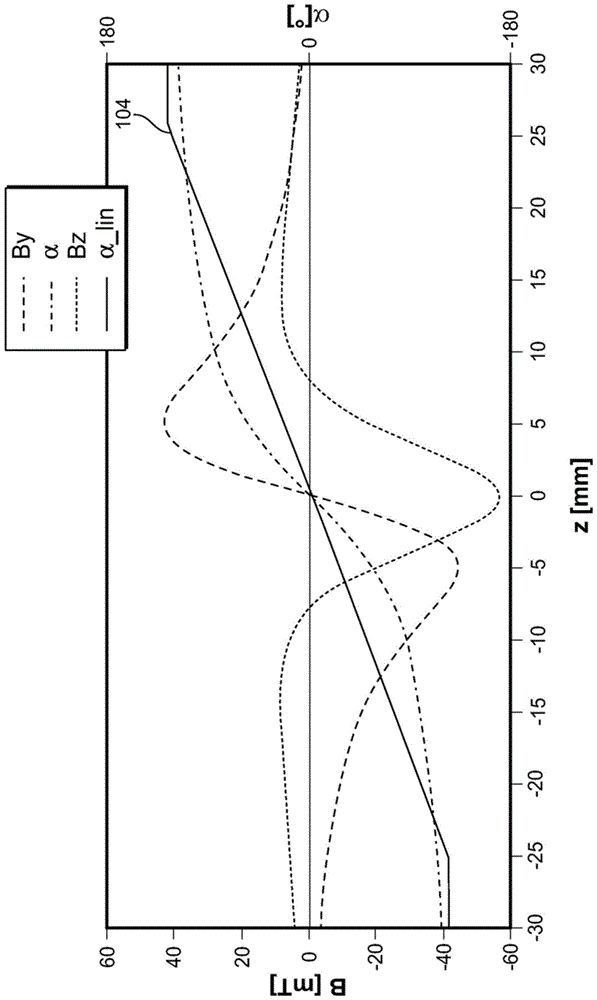

[0042] First refer to the following Figure 6 and figure 1 The present invention will be described in more detail.

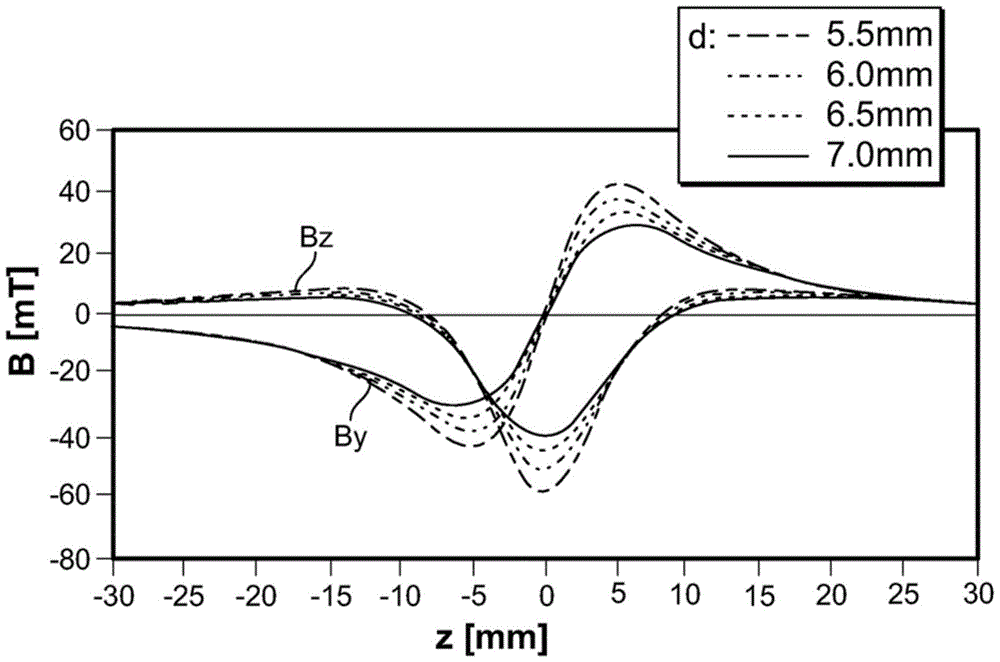

[0043] The displacement sensor arrangement according to the first embodiment is shown in figure 1 middle. The hall sensor 100 is installed to be fixed in position, and the permanent magnet 102 is supported to be linearly movable relative to the hall sensor 100 . The permanent magnet 102 has a pole configuration such that its south / north axis is oriented parallel to the direction of motion. In principle, however, the principles of the invention can also be used for arrangements in which the permanent magnets 102 have such a pole configuration that their south / north axes extend transversely with respect to the direction of motion. The permanent magnet 102 can be moved in two directions from the figure 1The zero position of is shifted outwards by about 25mm, for example. The Hall sensor 100 detects at least two orthogonal magnetic field components - one exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com