Skull repairing device

A skull and repair material technology, applied in the directions of internal bone synthesis, outer plate, fastening device, etc., can solve the problems of time-consuming, accident, prolapse, etc., and achieve the effect of simple and convenient processing, reduction of operation time, and reduction of intracranial pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

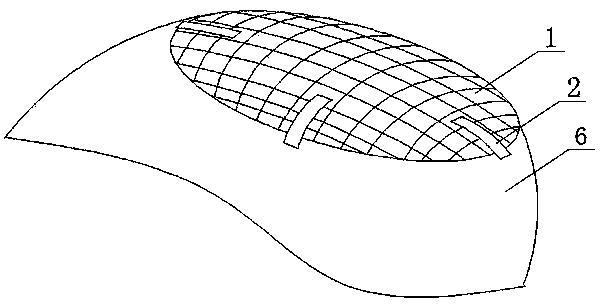

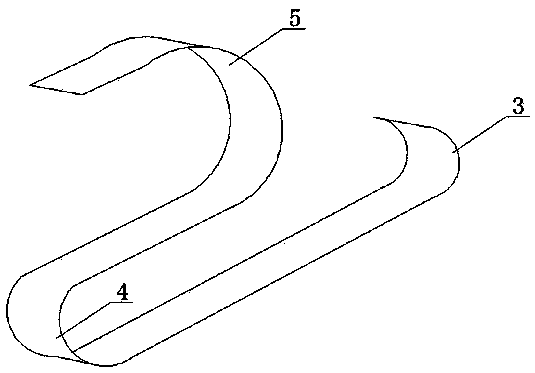

[0013] Such as figure 1 , 2 A cranioplasty device shown includes a repairing material 1 and a cranioplasty pin 2. The repairing material 1 is set in a mesh shape, and the cranioplasty pin 2 is composed of a repairing mesh hook 3, a repairing network card slot 4 and a skull clipping slot 5. Connected sequentially, there are 1-6 skull repair pins 2 for connecting the repair material 1 and the skull 6 .

[0014] The cross-section of the cranioplasty pin 2 is square.

[0015] The cranioplasty pin 2 is made of titanium metal.

[0016] There are four cranioplasty pins 2 . Since the generally injured surface of the skull is an arc-shaped structure, computer simulation is first used, and then the repair material 1 is produced. The repair material 1 is made of titanium metal and made into a mesh structure. The skull repair pin 2 is set to four for the best use effect. A skull modification pin 2 is first stuck on the four symmetrical points of the repairing material 1 through the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com