A kind of sugar electrolyte injection and preparation method thereof

An electrolyte injection and prescription technology, applied in the field of medicine, can solve the problems of insufficient clarity, inability to eat, pollution, etc., and achieve the effects of reducing the probability of decomposition, stable quality, and widely used in patient groups.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

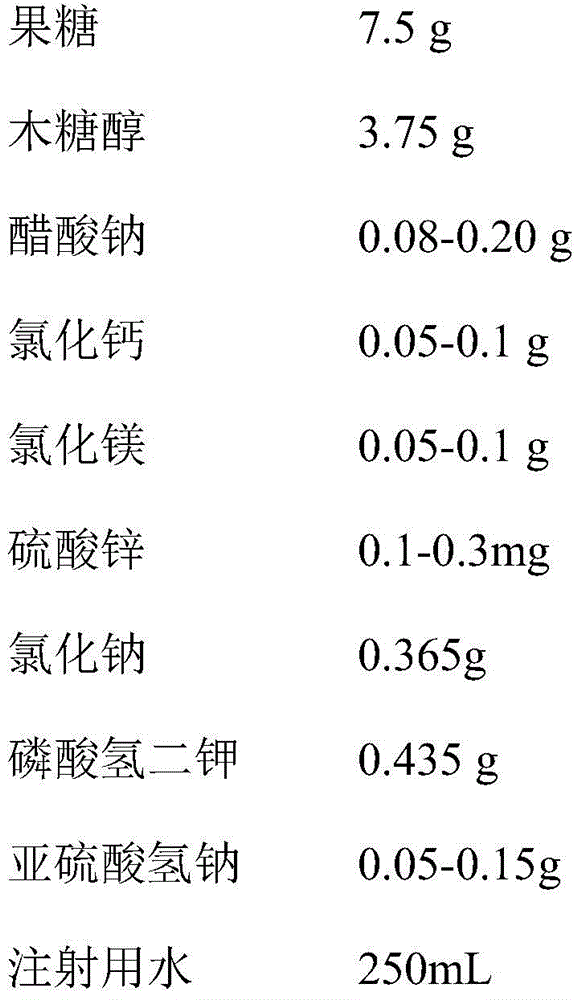

[0039] prescription:

[0040]

[0041]

[0042] The general dosage range of 2% citric acid is between 5-15mL, but its specific dosage is a point value in this embodiment, and the dosage value is subject to the final adjustment of the pH value of the sugar electrolyte injection at 5.0.

[0043] Preparation:

[0044] (1) Dissolve the disodium hydrogen phosphate of the prescribed amount in 80% water for injection, and adjust the pH value to 5.0 with citric acid. In this step, dipotassium hydrogen phosphate is dissolved alone, which can greatly reduce the crystallization and precipitation in the mixed sugar injection. Generate opportunities, and by adjusting the pH value, there will be no crystallization and precipitation when adding other raw and auxiliary materials, so as to ensure that the mixed sugar solution is in a stable solution state. It can ensure that the clarity and visible particles of the mixed sugar injection are qualified.

[0045](2) drop into the glucose ...

Embodiment 2

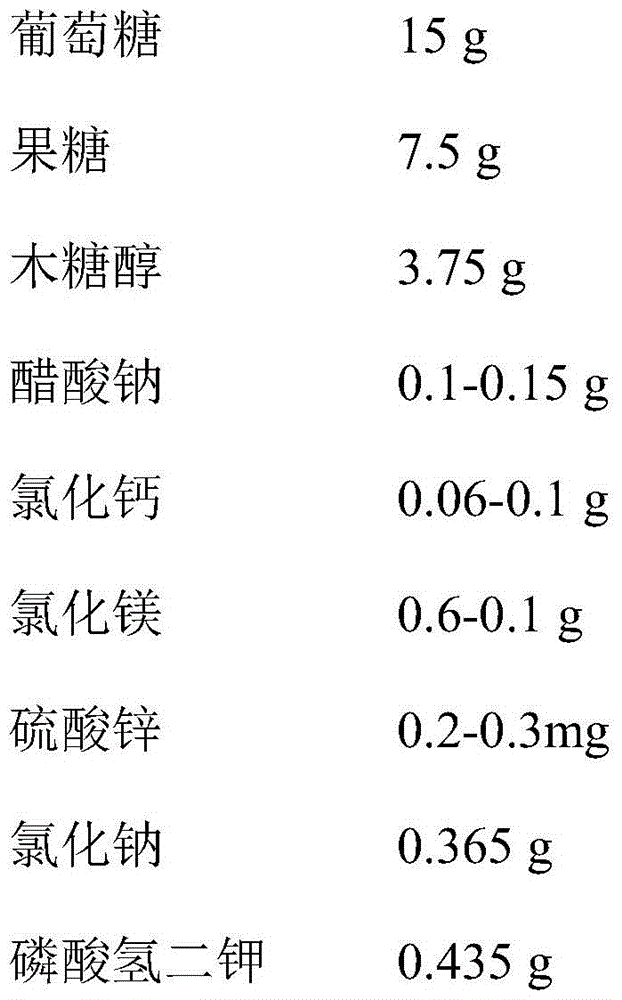

[0052] prescription:

[0053]

[0054]

[0055] The general dosage range of 2% citric acid is between 5-15mL, but its specific dosage is a point value in this embodiment, and the dosage value is subject to the final adjustment of the pH value of the sugar electrolyte injection at 5.0.

[0056] Preparation:

[0057] (1) Dissolve the dipotassium hydrogen phosphate of the prescribed amount in 80% water for injection, and adjust the pH value to 4.5 with citric acid. In this step, the dipotassium hydrogen phosphate is dissolved alone, which can greatly reduce the crystallization and precipitation in the mixed sugar injection. Opportunities are generated, and by adjusting the pH value, no crystallization and precipitation occur when other raw and auxiliary materials are added, so as to ensure that the mixed sugar solution is in a stable solution state. It can ensure that the clarity and visible particles of the mixed sugar injection are qualified.

[0058] (2) drop into the ...

Embodiment 3

[0066] prescription:

[0067]

[0068]

[0069] The general dosage range of 2% citric acid is between 5-15mL, but its specific dosage is a point value in this embodiment, and the dosage value is subject to the final adjustment of the pH value of the sugar electrolyte injection at 5.0.

[0070] Preparation:

[0071] (1) Dissolve the dipotassium hydrogen phosphate of the prescribed amount in 80% water for injection, and adjust the pH value to 4.8 with citric acid. In this step, the dipotassium hydrogen phosphate is dissolved alone, which can greatly reduce the crystallization and precipitation in the mixed sugar injection. Opportunities are generated, and by adjusting the pH value, no crystallization and precipitation occur when other raw and auxiliary materials are added, so as to ensure that the mixed sugar solution is in a stable solution state. It can ensure that the clarity and visible particles of the mixed sugar injection are qualified.

[0072] (2) drop into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com