Uniformly mixing and filtering integrated processing mechanism for specimen

A technology of mixing and sampling, applied in mixers with rotating containers, mixers, filtration and separation, etc., can solve the problems of incomplete filtration, automatic equipment coordination, time-consuming and labor-intensive, etc., to achieve the effect of simple structure and continuous filtration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

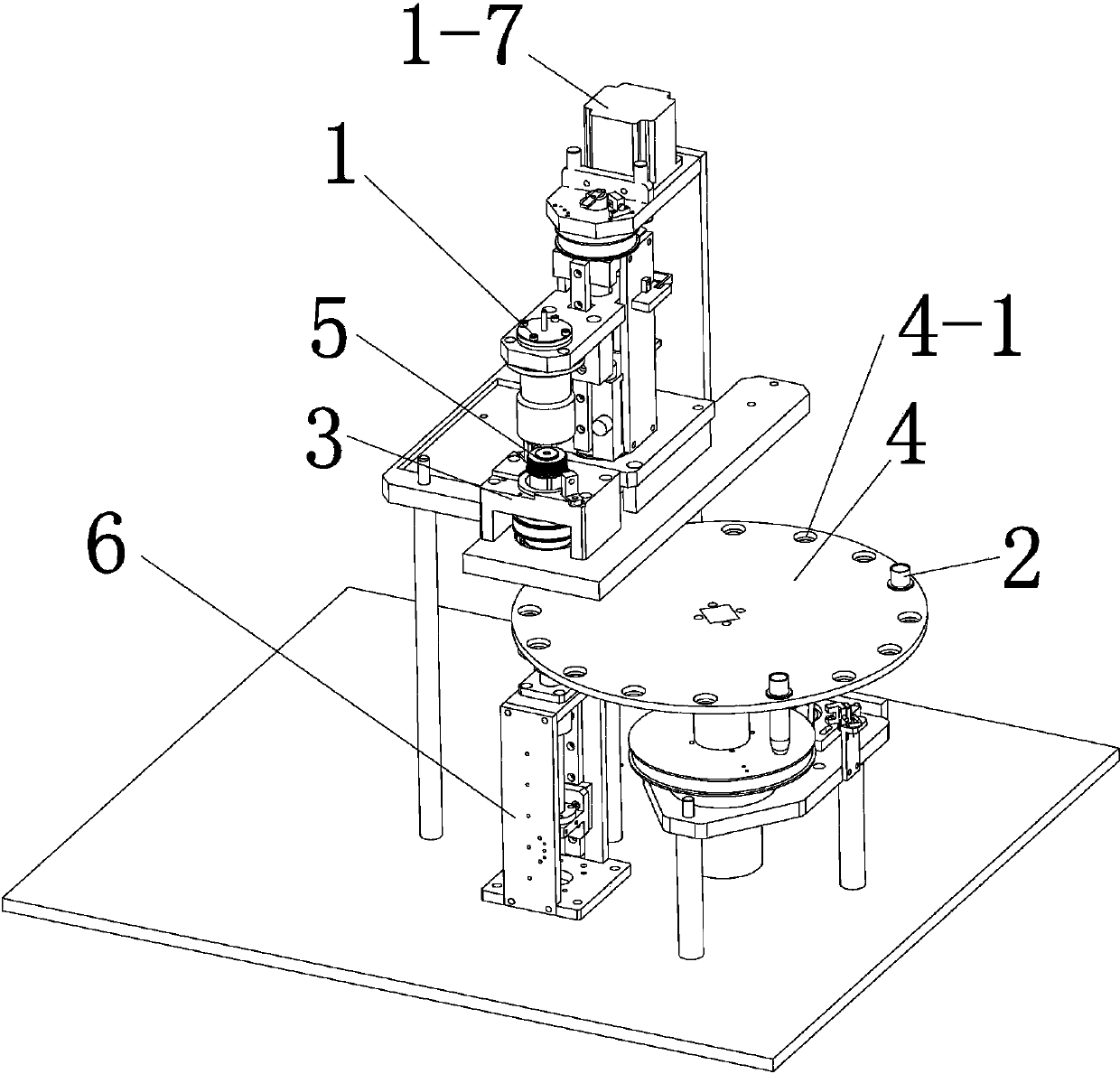

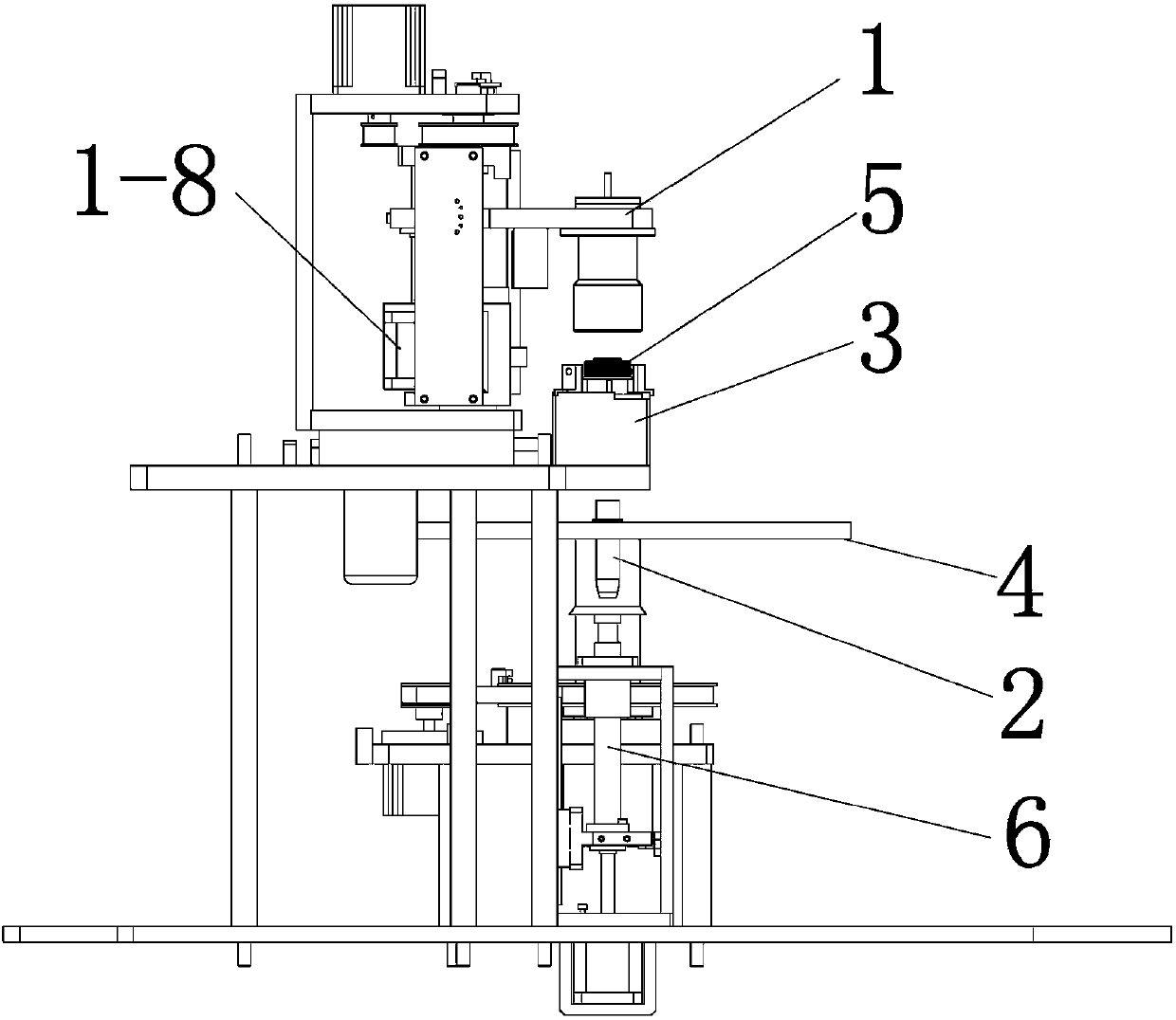

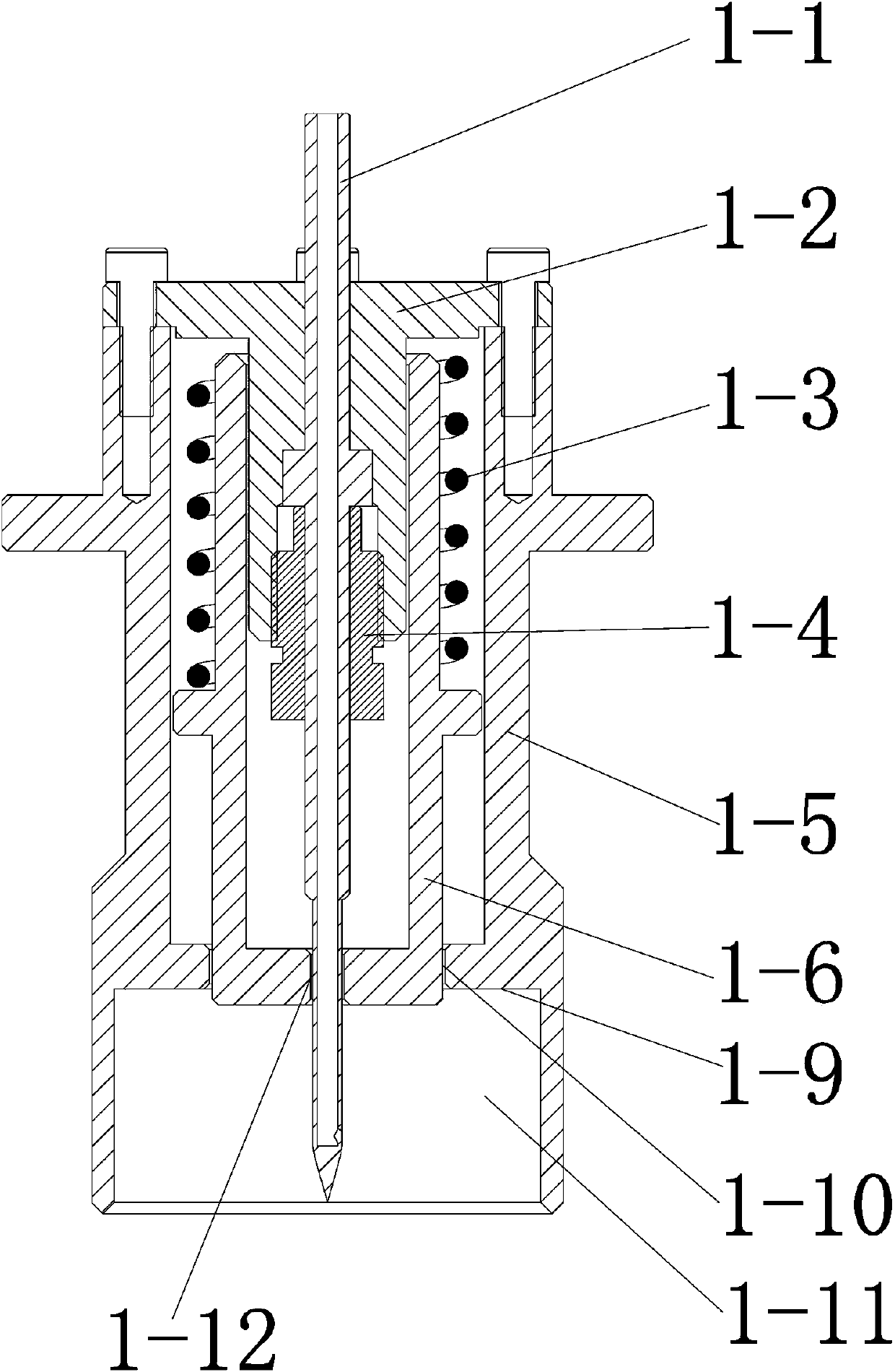

[0028] Such as figure 1 - Figure 9 Shown is an embodiment of the present invention, a specimen mixing and filtering integrated processing mechanism, including a filtering and ventilating mechanism 1, a test tube 2, a mixing mechanism 3, a test tube carrying mechanism 4, a specimen container 5 and a jacking mechanism 6 coordinated in sequence ; Wherein: the filter ventilation mechanism 1 is driven by the motor to move up and down and rotate left and right, the filter ventilation mechanism 1 has a top abutment surface 1-9, and a ventilation needle 1-1, the filter ventilation mechanism 1 rotates and presses down, and its top abutment surface 1-9 presses the sample container 5, and the ventilation needle 1-1 is inserted into the sample container 5 to ventilate; the mixing mechanism 3 is arranged under the filter and ventilation mechanism 1, and is driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com