A stamping die for convex hull of display backplane

A technology for stamping dies and displays, applied in the field of stamping dies, can solve the problems of easy cracking, high manufacturing difficulty, low yield of convex hull, etc., and achieve the effect of reducing stress and improving yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

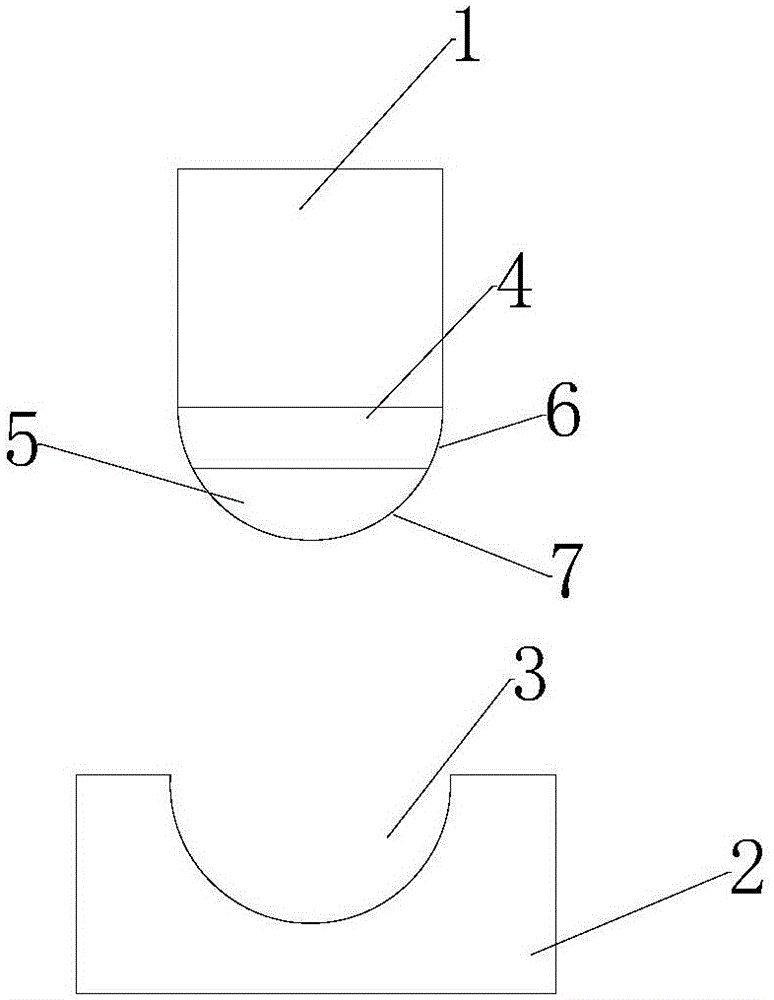

[0019] figure 1 It is a structural diagram of a stamping die for display back panel convex provided by Embodiment 1 of the present invention.

[0020] A stamping die for convex hull of a display backplane, comprising: a punch 1 and a die 2 located below the punch 1, the center of the die 2 is recessed downward to form a hollow cavity 3, the The punch 1 includes a fixed punch portion 4 and a movable punch portion 5, the fixed punch portion 4 includes a first core portion 6 and a first cavity 8, and the movable punch portion 5 includes a movable core portion 7 and a movable support part 10, the movable support part 10 is located in the first cavity 8 and closely fits with the first cavity 8, the first core part 6 and the movable core part 7 A core is formed, and the shape of the core and the shape of the cavity 3 are the same as that of the convex hull.

[0021] In this embodiment, the present invention decomposes the stamping process into two stampings by fixing the punch hea...

Embodiment 2

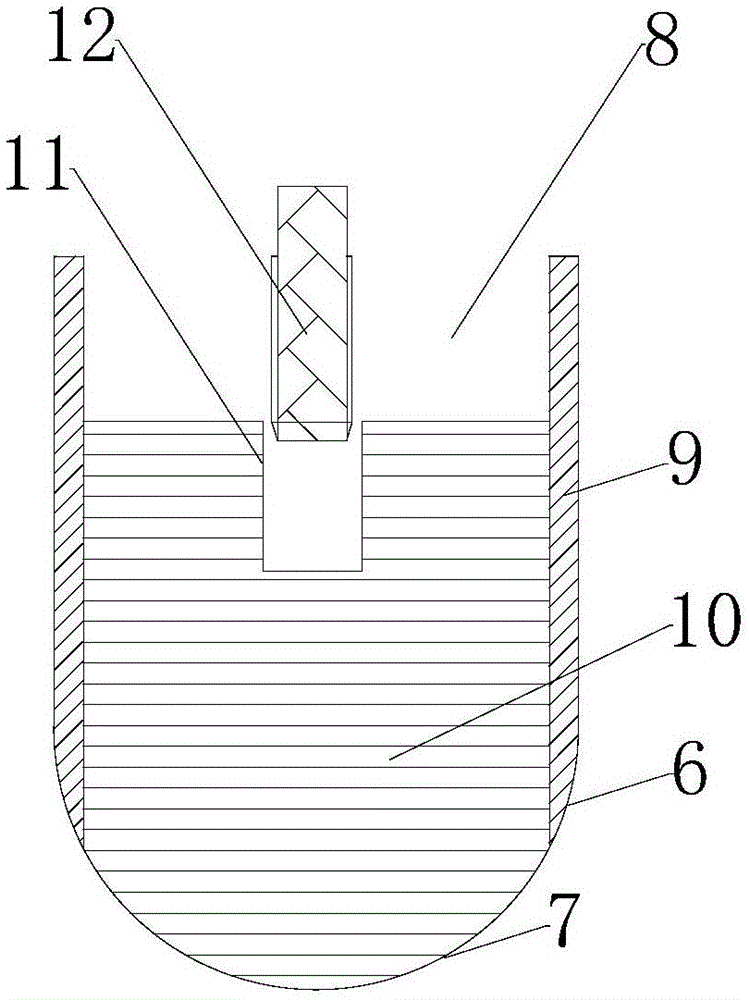

[0029] Such as image 3 As shown, when the stamping die is not working, the movable punch part 5 is located in the first cavity 8, and the fixed punch part 4 is first in contact with the display backplane during the stamping process of the punch 1, When the fixed punch part 4 enters the cavity 3 completely, the screw rod 12 cooperates with the threaded structure 11 to make the movable punch part 5 move from the first cavity 8 to the The movement in the cavity 3 is used to stamp the back panel of the display for the second time. When the movable core 7 fits with the cavity 3, the movable punch 5 stops, and the stamping process is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com