A kind of laser cutting machine and its cutting method

A laser cutting machine, laser technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of low production efficiency, high production cost, difficulty in mass production, etc., to improve production efficiency and production cost. low, high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

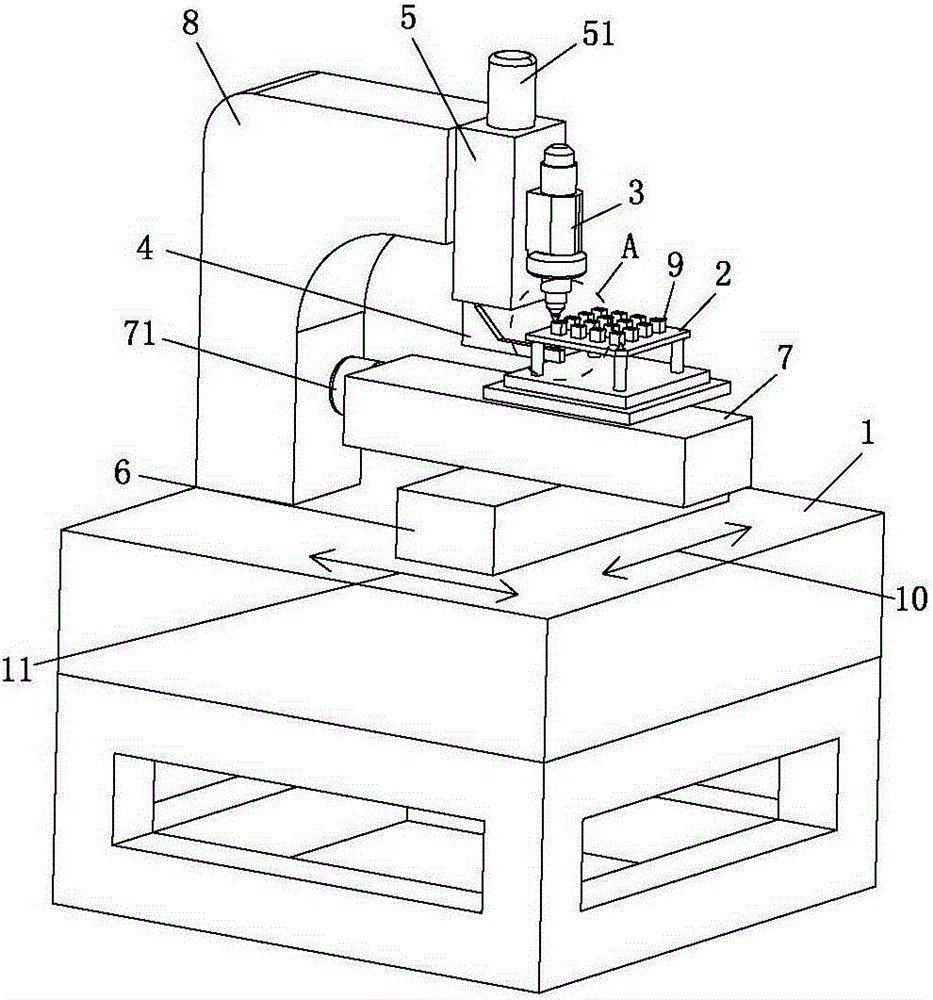

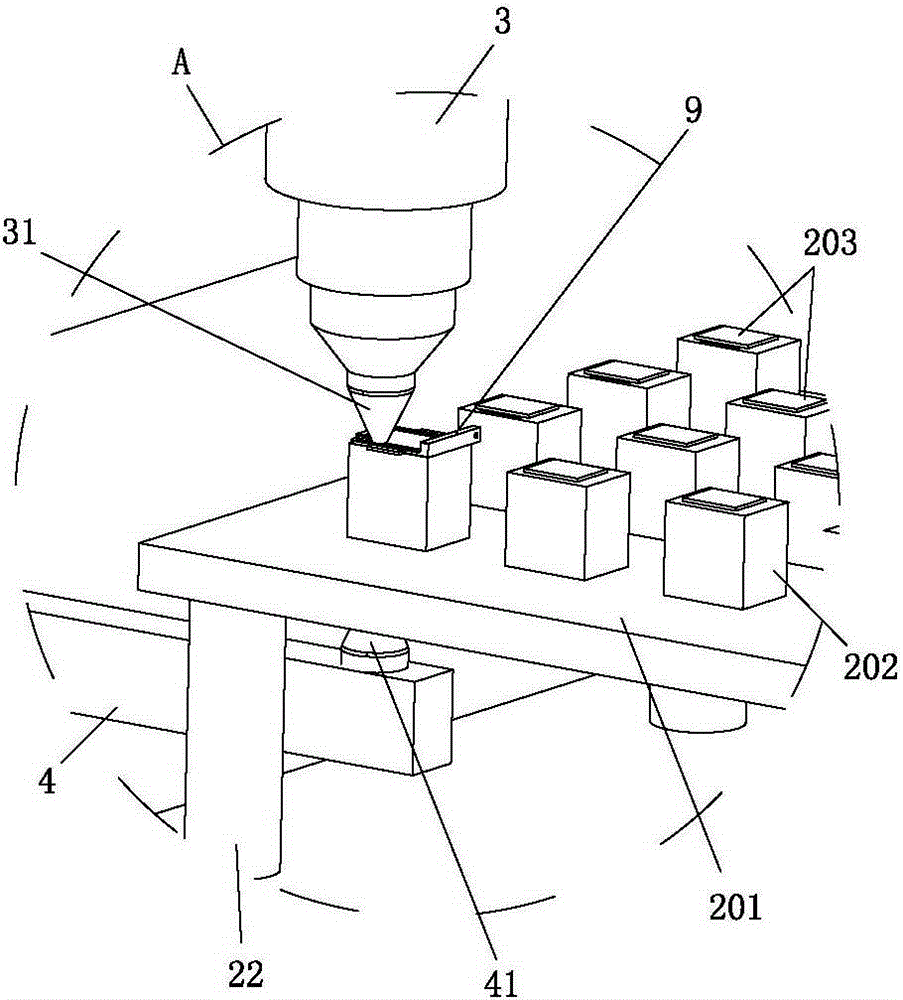

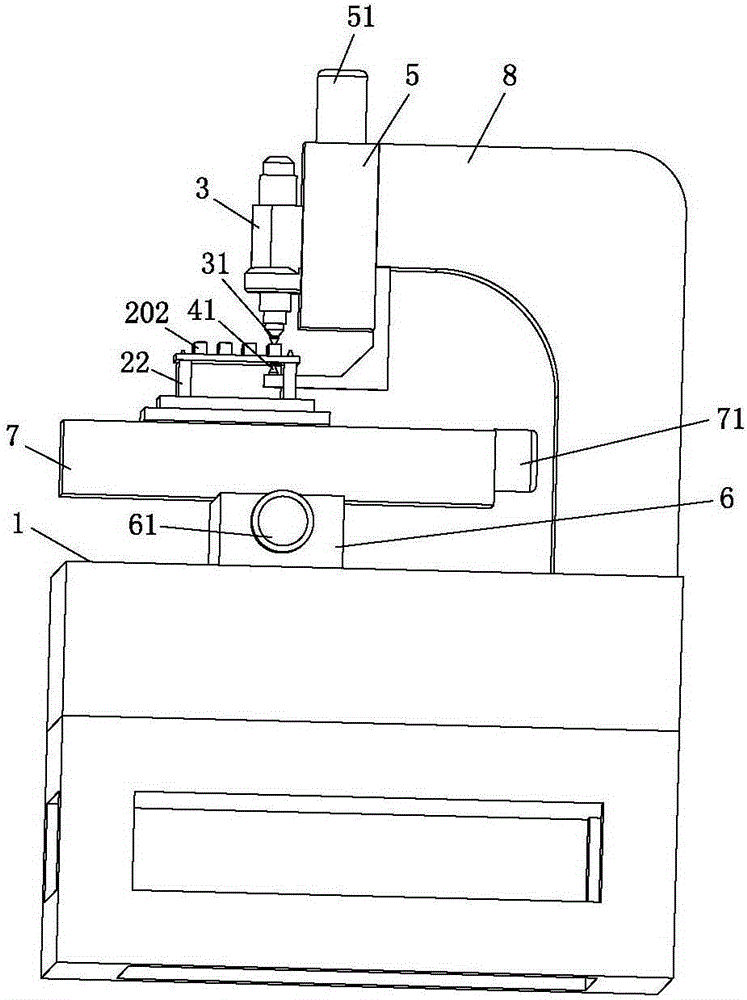

[0058] See Figure 1 to Figure 8 . A laser cutting machine in this embodiment includes a machine tool platform 1, a clamping fixture 2, an emitting device 3 for emitting laser light and a first shielding gas, a first moving mechanism for moving the clamping fixture 2, and a The second moving mechanism 5 for moving the launching device 3, and the blowing mechanism 4 for blowing the second protective gas; the launching device 3 includes the upper part of the clamping fixture 2, and emits the laser and the first protective gas in the same direction The injection nozzle 31; the blowing mechanism 4 includes a blowing nozzle 41 coaxially opposite to the injection nozzle 31; the clamping jig 2 is provided with a blowing channel 205 for blowing the second protective gas. The laser cutting machine of the present invention is provided with the blowing mechanism 4 for blowing the second protective gas, that is, the laser cutting machine has the injection of the first protective gas in t...

Embodiment 2

[0069] A cutting method of a laser cutting machine in this embodiment uses the laser cutting machine of Embodiment 1 for cutting, and the cutting method of the laser cutting machine is C-type, that is, a wire cutting method. The wire cutting method makes the laser cutting machine of the present invention have the advantages of high efficiency and mass production.

Embodiment 3

[0071] In the cutting method of a laser cutting machine in this embodiment, the laser cutting machine in Embodiment 1 is used for cutting. During the cutting process, the first protective gas blown is an inert gas, wherein the inert gas includes helium, neon gas, argon, krypton and xenon; the blown second protective gas is nitrogen, so that the cut alloy product 9 can avoid being easily oxidized due to high temperature during the cutting process, and can also make the The burrs generated during cutting are carbonized, so that the burrs are easily blown away, so that the cut alloy product 9 has the advantages of less number of burrs, small size of burrs, and good quality of the cut surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com