Injection molding machine

An injection molding machine and pedestal technology, which is applied in the field of injection molding machines, can solve the problems of damaging the pedestal and the large force exerted by the pedestal for fixing the sliding parts, and achieves the effect of restraining the damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

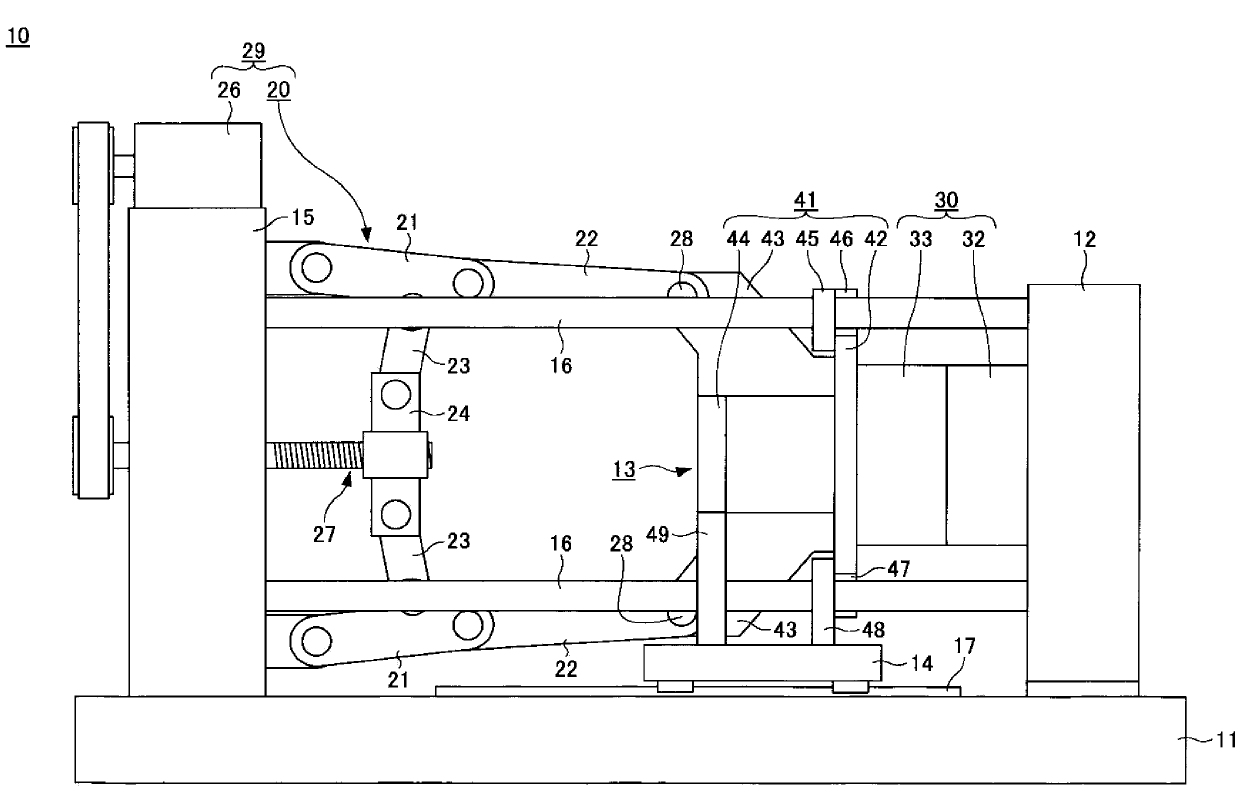

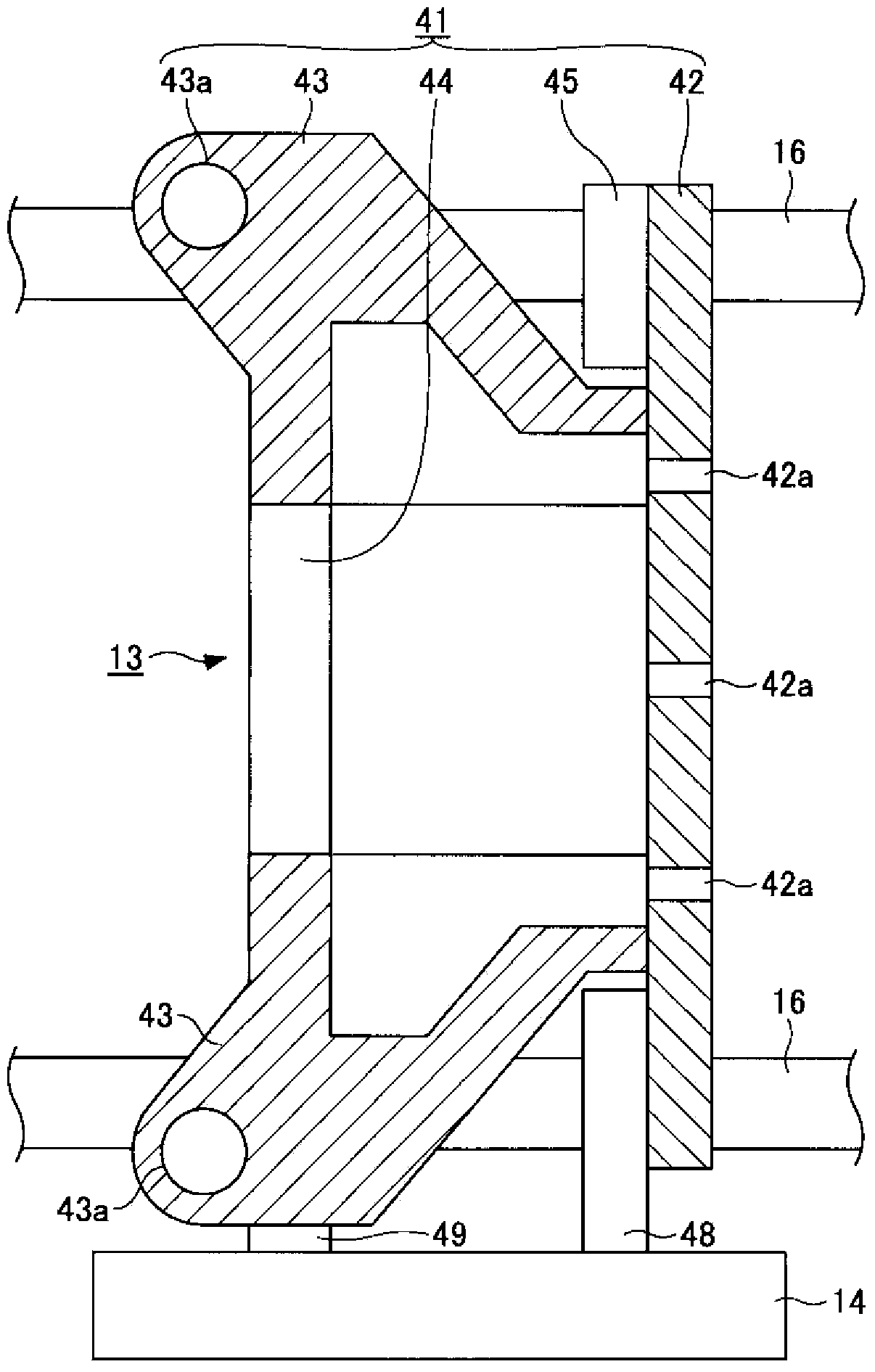

[0039] figure 1 It is a figure which shows the state at the end of mold closing of the injection molding machine concerning 1st Embodiment of this invention. figure 2 It is a sectional view showing the structure of the movable platen according to the first embodiment of the present invention.

[0040] Such as figure 1 As shown, the injection molding machine 10 includes, for example, a frame 11, a fixed platen 12, a movable platen 13, a base 14, a rear platen 15 as a support, a connecting rod 16, a guide 17, a toggle mechanism 20, a mold clamping motor 26, and the like. .

[0041] The fixed platen 12 can be fixed on the frame 11 . The rear platen 15 is arranged at a distance from the fixed platen 12 . The rear platen 15 and the fixed platen 12 are connected by a plurality of (for example, four) connecting rods 16 . The rear platen 15 is mounted on the frame 11 so as to be able to advance and retreat in order to allow the extension of the connecting rod 16 during mold clos...

no. 2 Embodiment approach

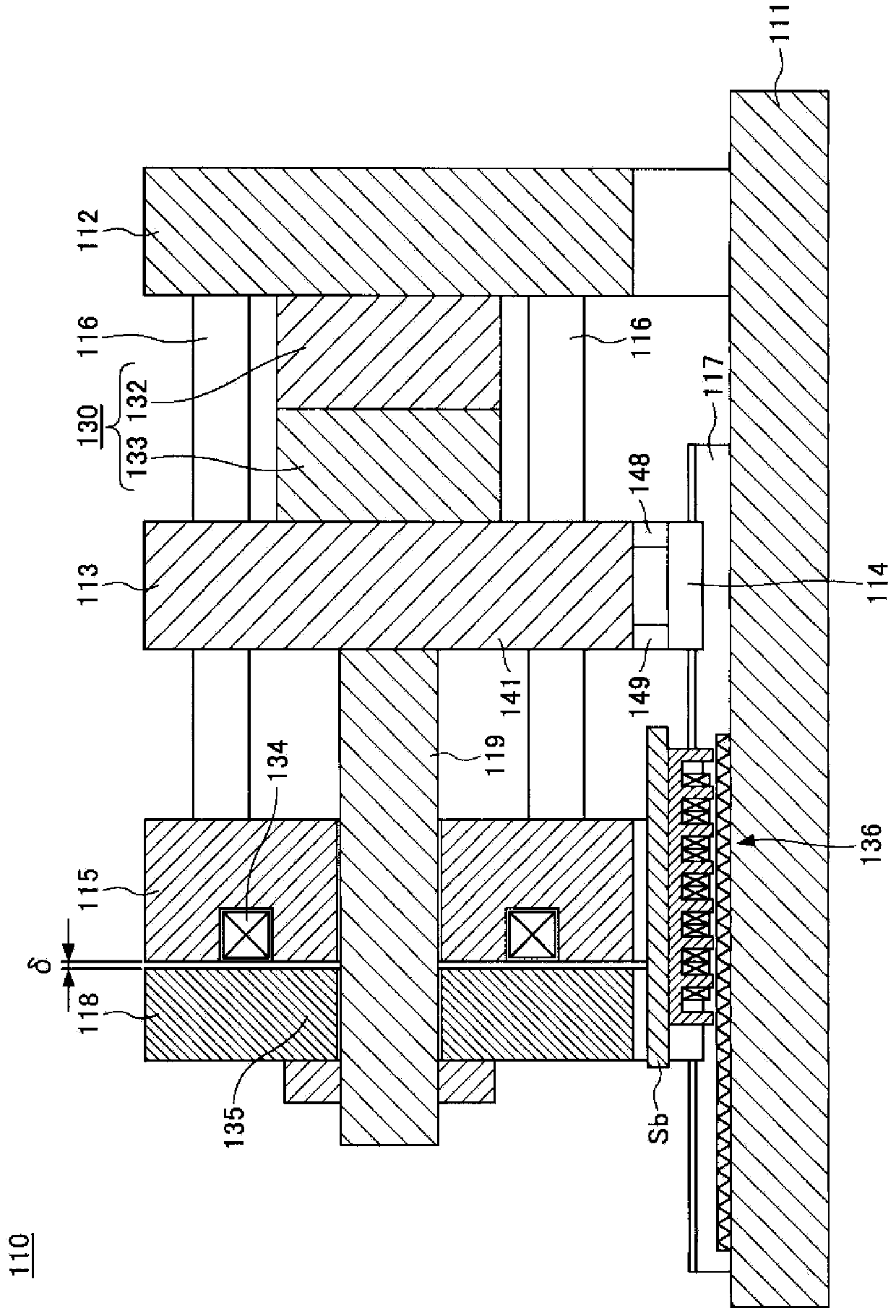

[0069] In the first embodiment, the toggle mechanism and the mold clamping motor 26 constitute the mold clamping force generation mechanism. In this embodiment, however, the mold clamping force generation mechanism is constituted by the electromagnet formed on the rear platen and the suction portion formed on the suction plate.

[0070] image 3 It is a sectional view showing the state of the injection molding machine according to the second embodiment of the present invention at the end of mold closing. Such as image 3 As shown, the injection molding machine 110 includes, for example, a frame 111 , a fixed platen 112 , a movable platen 113 , a base 114 , a rear platen 115 , connecting rods 116 , guides 117 , suction plates 118 , and rods 119 .

[0071] The rear platen 115 can be fixed on the frame 111 . The fixed platen 112 is disposed at a distance from the rear platen 115 . The fixed platen 112 and the rear platen 115 are connected by multiple (for example, four) conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com