A Die Clamping Mechanism with Internal Circulation and Two Plates for Easy Debugging

An internal circulation, two-plate technology, applied to the field of the internal circulation two-plate mold clamping mechanism, can solve the problems of easy failure, cumbersome maintenance, complex mold clamping cylinder structure, etc., to achieve fast maintenance and repair, mechanical failure, and simple debugging process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

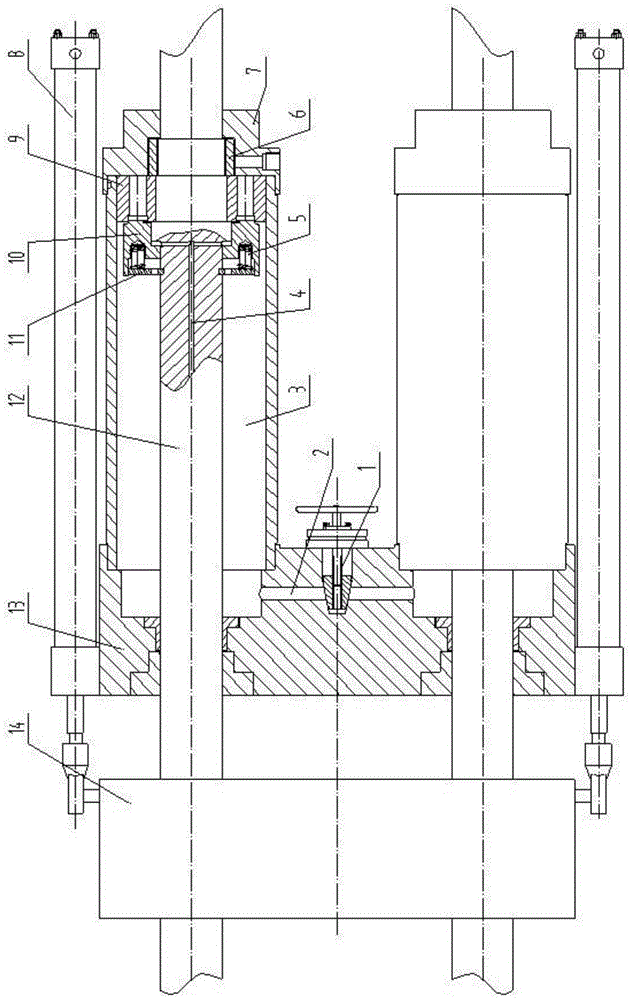

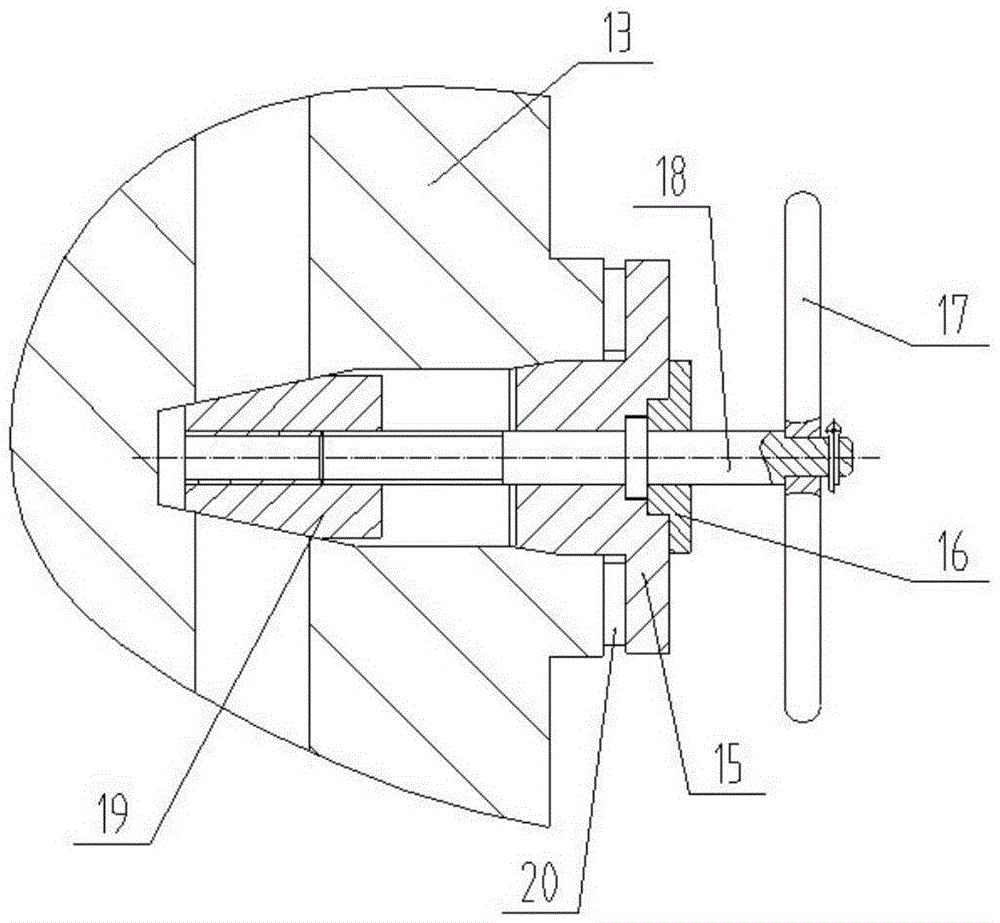

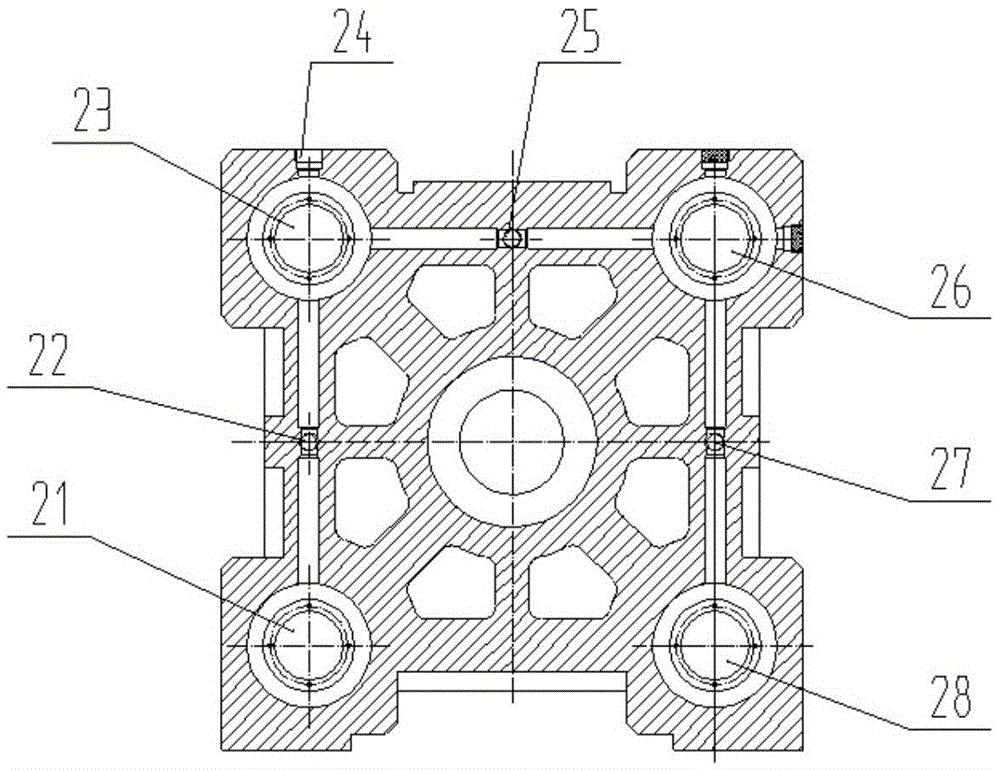

[0011] figure 1 It is a diagram of an internal circulation two-plate mold clamping mechanism that is convenient for debugging. The inner circulation two-plate mold clamping mechanism includes a movable platen 14, a fixed platen 13, a clamping cylinder 3, a mold-moving cylinder 8, an ejection cylinder (not shown) and an opening and closing valve 1 installed on the fixed platen 13; a mold-moving cylinder 8, there are two, arranged symmetrically according to the diagonal, to control the movement of the movable platen 14; there are four clamping oil cylinders 3, which are evenly distributed on the four corners of the fixed platen 13 according to the center line, to provide clamping pressure; inside the clamping oil cylinder 3 there are The piston that controls the on and off of the oil chambers on both sides, the internal piston is composed of a retaining ring 11, a spring 5, a mold clamping slide valve 10, a mold clamping piston 9, and a mold clamping rear nut 6, etc.; the retain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com