Device preventing raw material from blocking raw material box

A technology for raw materials and powder raw materials, applied in packaging, loading/unloading, transportation and packaging, etc., can solve problems such as equipment failure, affecting the fluidity of raw materials, affecting the normal progress of production, etc., to prevent accumulation and improve fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the present invention more easily understood, the present invention will be further described below in conjunction with accompanying drawing:

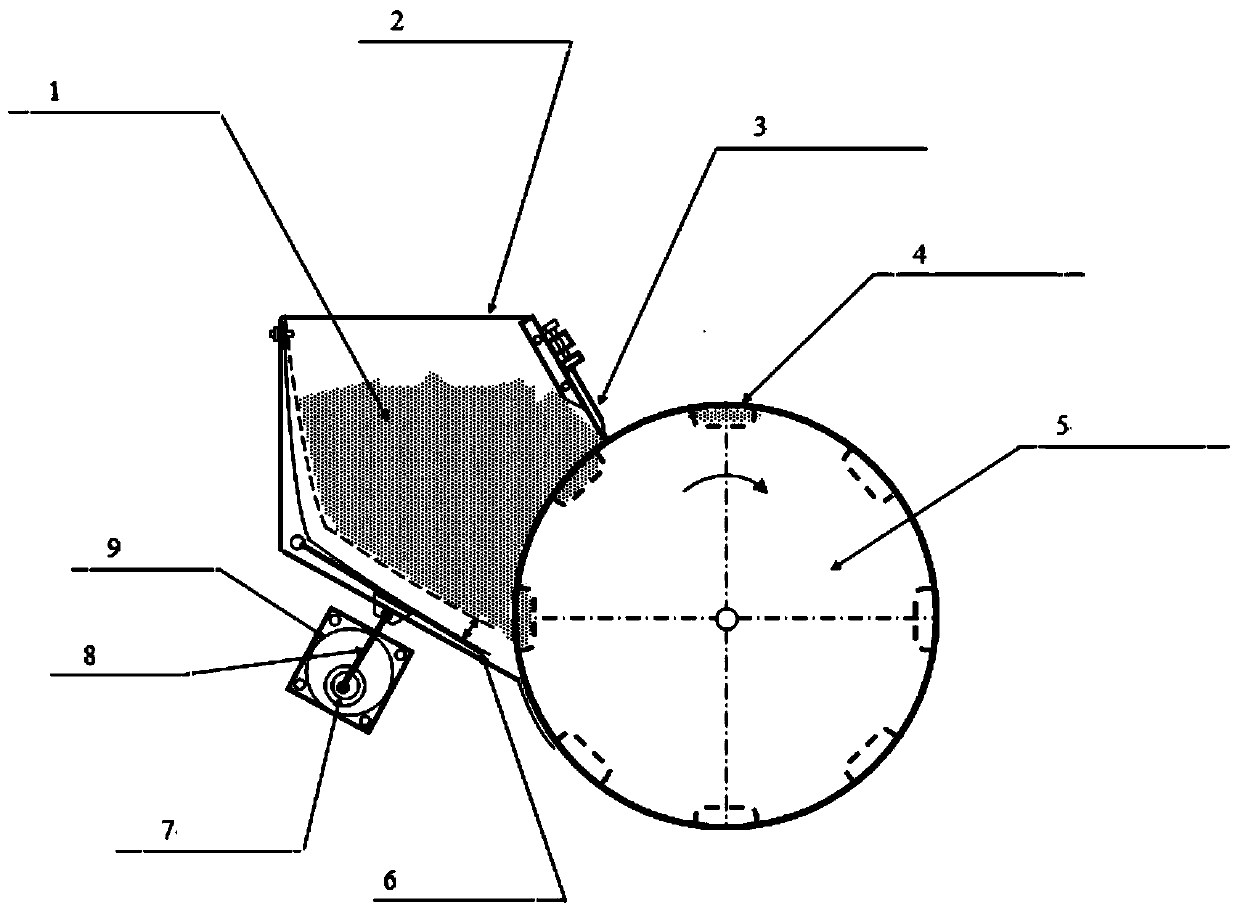

[0012] Such as figure 1 As shown, the device for preventing raw material clogging of the present invention consists of powder raw material (1), raw material standby box (2), uniform scraper (3), metering pool (4), transfer drum (5), swing bottom plate (6) , eccentric wheel (7), connecting rod (8), motor (9). Put the powder raw material (1) into the raw material standby box (2), the powder raw material (1) is attached to the cylinder wall of the transfer drum (5), at this time, the motor (9) drives the swing bottom plate (6) to reciprocate The swing frequency of the swing bottom plate (6) can be set according to the requirements of the product, and the powder raw material (1) at the bottom of the raw material standby box (2) is continuously turned and pushed to the transfer roller (5) at the same time. . The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com