Knife structure in a placket machine

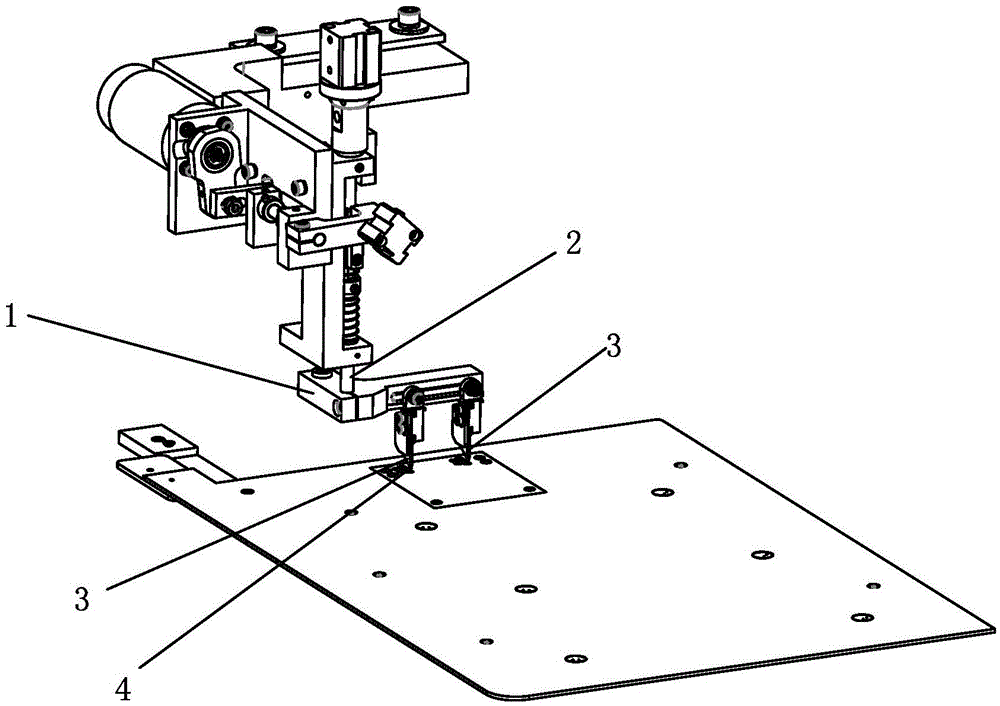

A placket machine and middle-knife technology, which is applied to sewing machine components, textiles and papermaking, garment piece transporters, etc., can solve the problems of shaking, larger gap, and poor stability of the middle-knife 3, so as to reduce the middle-knife Loss, smooth up and down movement, and the effect of improving the quality of cloth cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

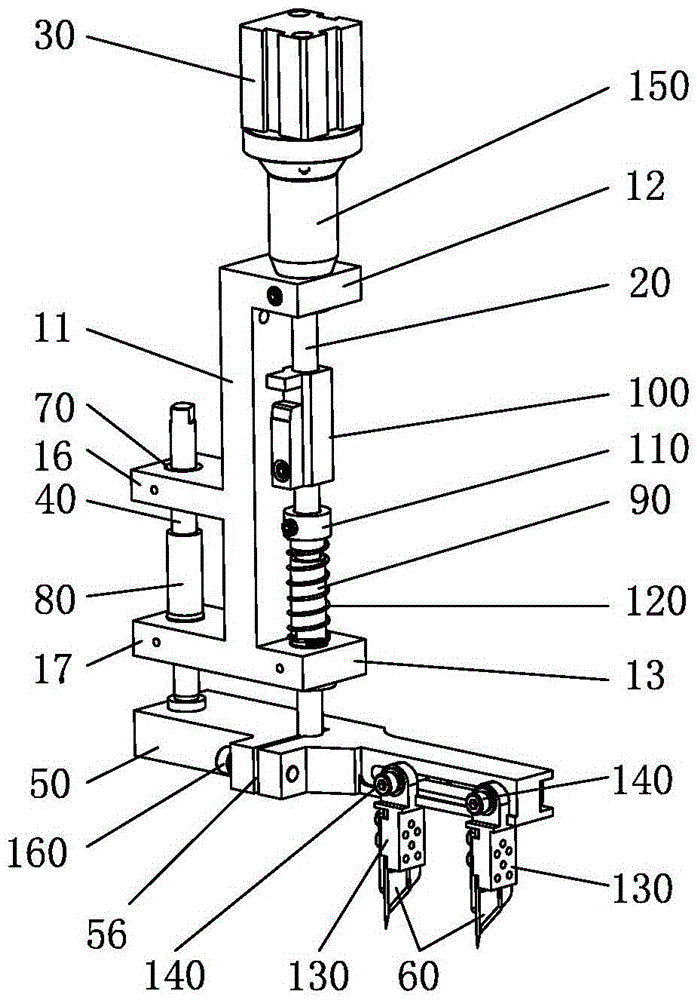

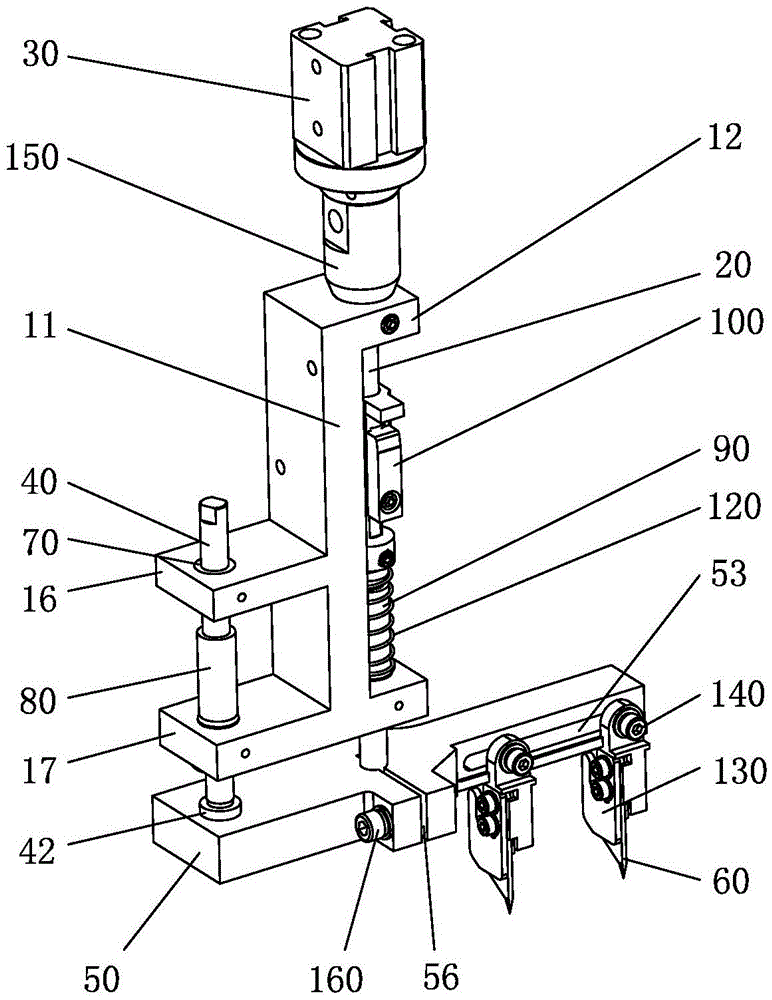

[0026] The present invention will be further described below with specific embodiment, see figure 2 -8:

[0027] A middle knife structure of a fly machine, including a connecting block 10, a main shaft 20 arranged on the connecting block 10, the upper end of the main shaft 20 protrudes outside the upper end of the connecting block 10, and the lower end extends outside the lower end of the connecting block 10, The top of the main shaft 20 is provided with a driver to drive its action, and one side of the connecting block 10 is provided with a guide shaft 40, the lower end of the guide shaft 40 stretches out of the lower end of the connecting block 10, and the lower end of the guide shaft 40 is fixed to the middle knife One end of frame 50 is connected, and the lower end of main shaft 20 is connected with the middle part of middle knife holder 50, and the other end of middle knife holder 50 is provided with middle knife 60.

[0028] The above-mentioned connection block 10 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com