Novel double-suction vortex pump

A swirl pump, a new type of technology, applied in the direction of pumps for special fluids, pumps, components of pumping devices for elastic fluids, etc. Increased efficiency, improved overall performance, overcoming inefficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0019] The novel double-suction swirl pump of the present invention is installed to work underwater, and the water pump is installed on the support of the platform through the bearing body support. The position of the new double-suction swirl pump on the underwater platform makes the water outlet tightly connected with the pipeline.

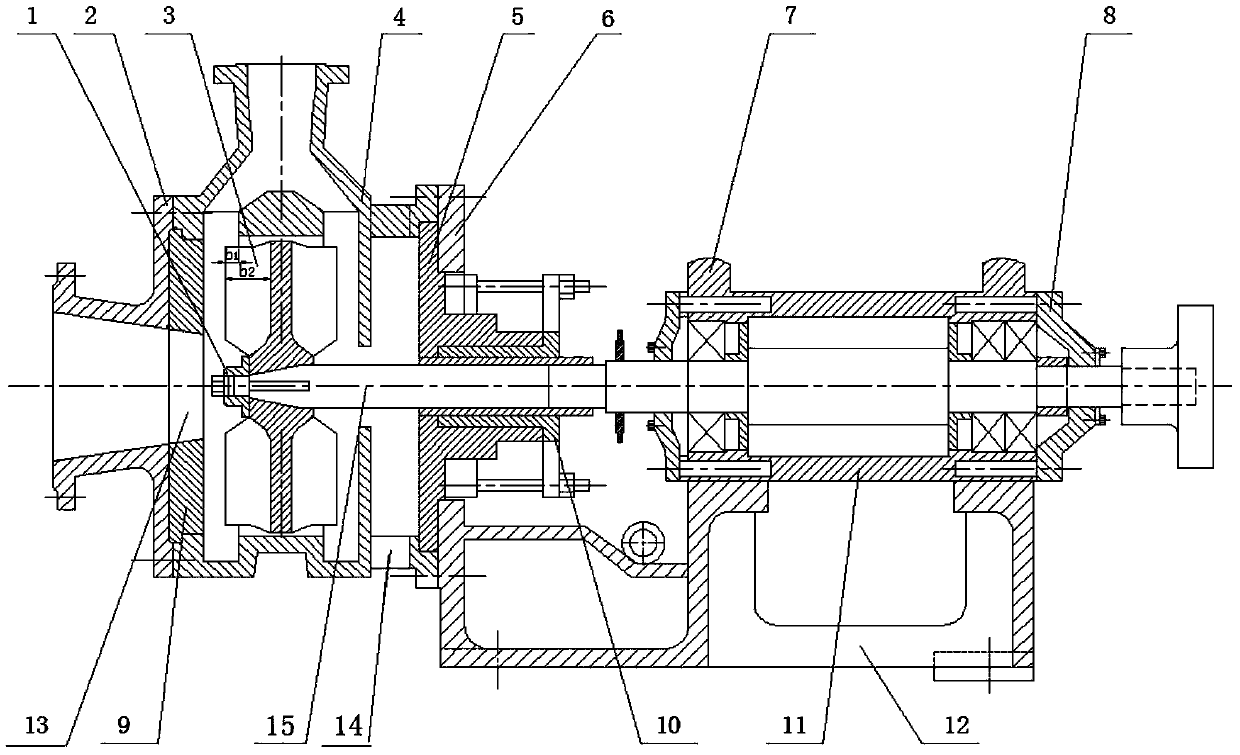

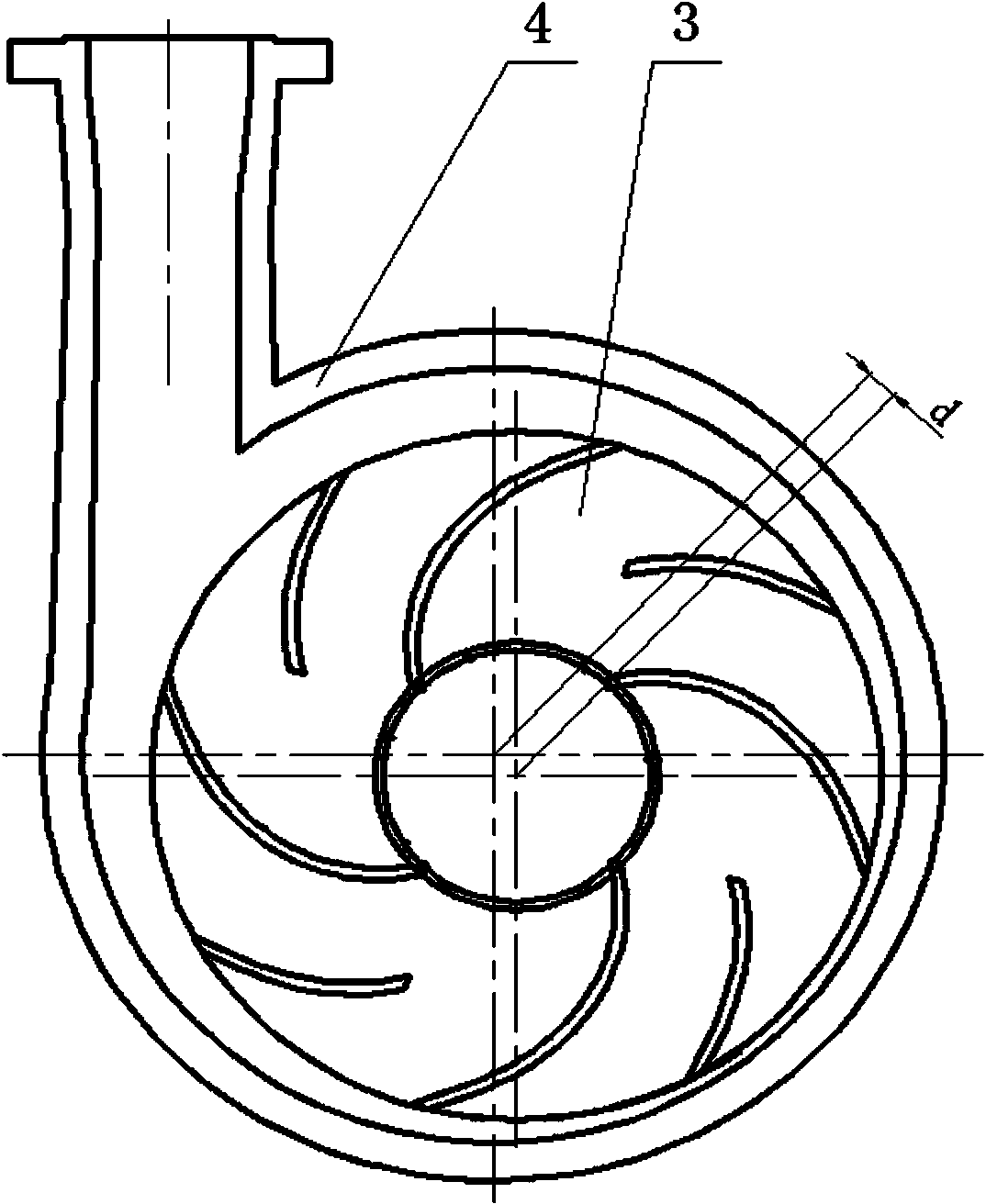

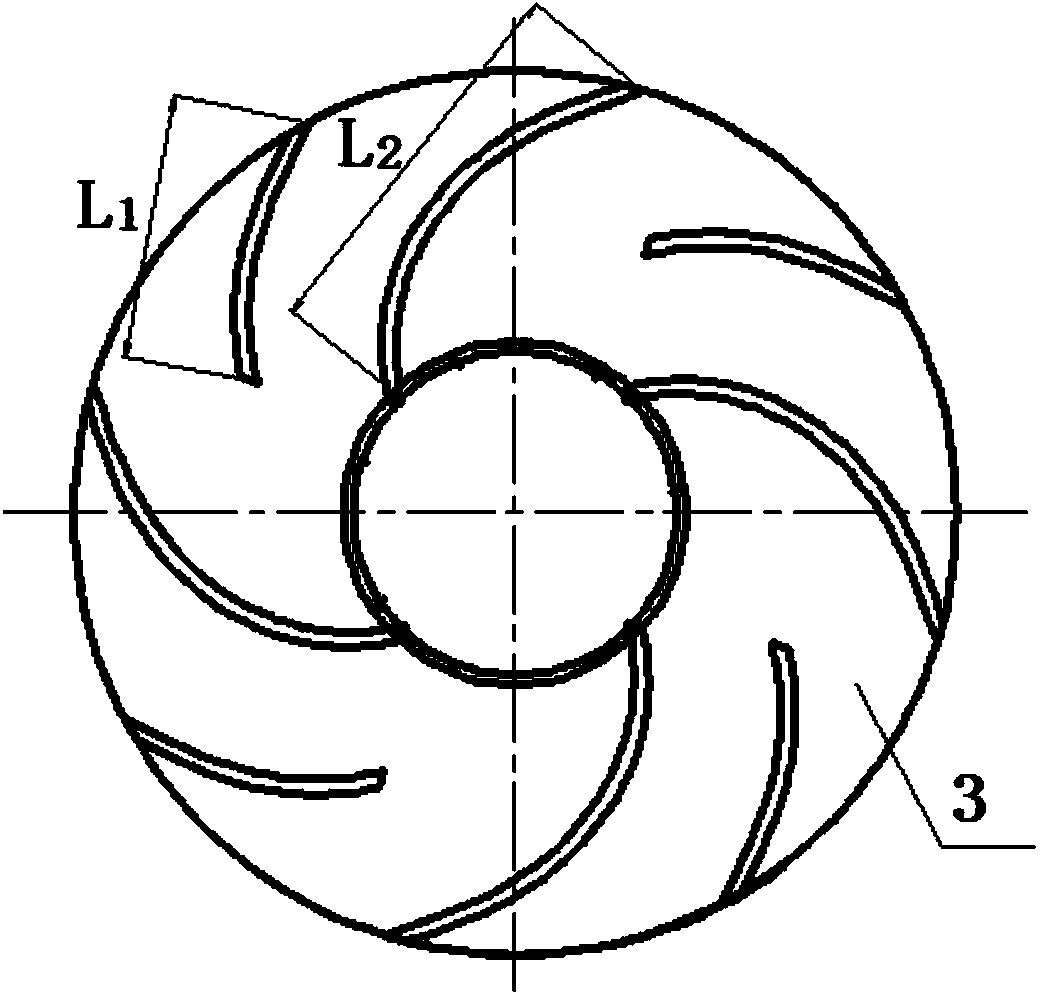

[0020] Such as figure 1 As shown, the novel double-suction swirl pump includes a double-suction impeller 3, a main shaft 15, a front cover 2, a pump body 4, a packing chamber 66, a bearing body upper bracket 7, a right bearing gland 8, a wear plate 9, a packing Gland 10, bearing body 11, bearing body lower bracket 12, the main shaft 15 is assembled on the bearing body 11, one end of the main shaft 15 is connected with the motor, and the dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com