Digital photoelectric temperature sensor

A temperature sensor and photoelectric technology, applied in the field of temperature sensors, can solve the problems of affecting normal operation, frequent replacement, high cost, etc., and achieve the effect of improving measurement accuracy and facilitating disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

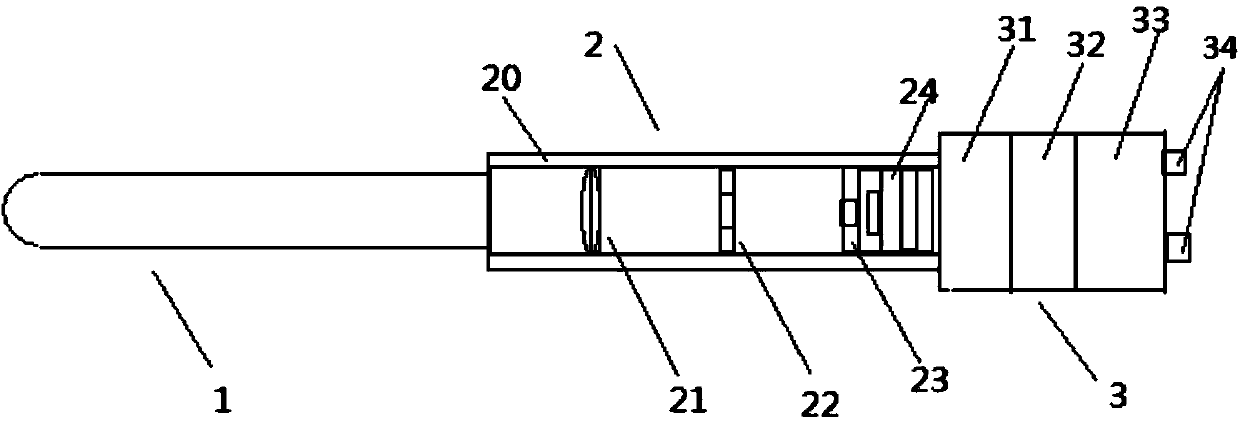

[0024] Such as figure 1 , figure 2 As shown, a kind of digital photoelectric temperature sensor proposed by the present invention comprises: temperature sensing tube 1, photoelectric conversion module 2 and digital processing module 3; Wherein:

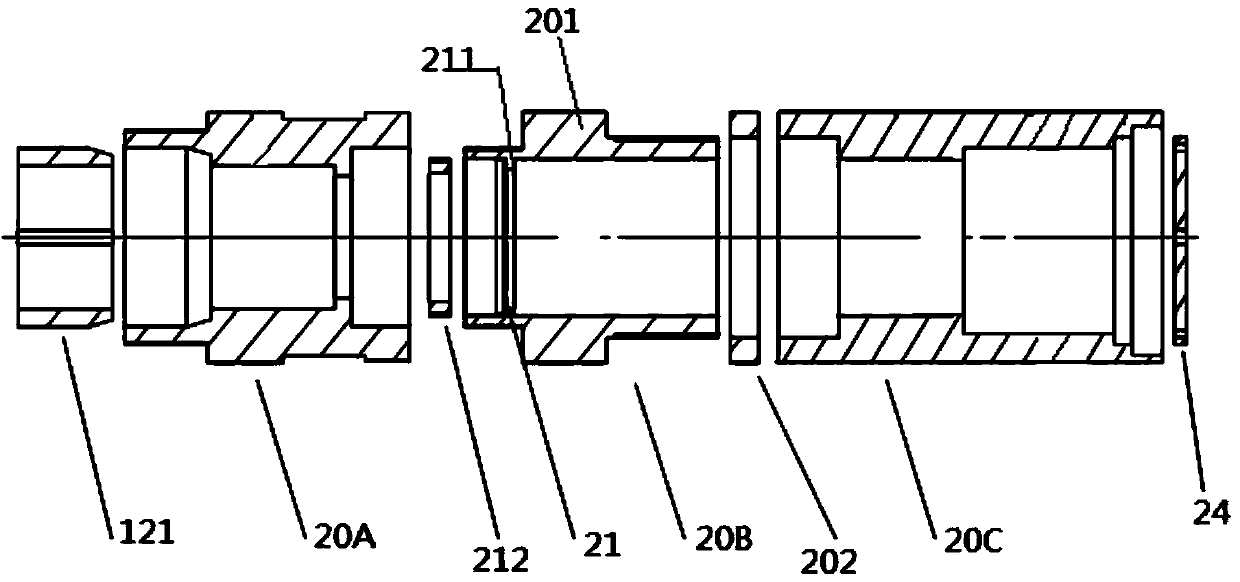

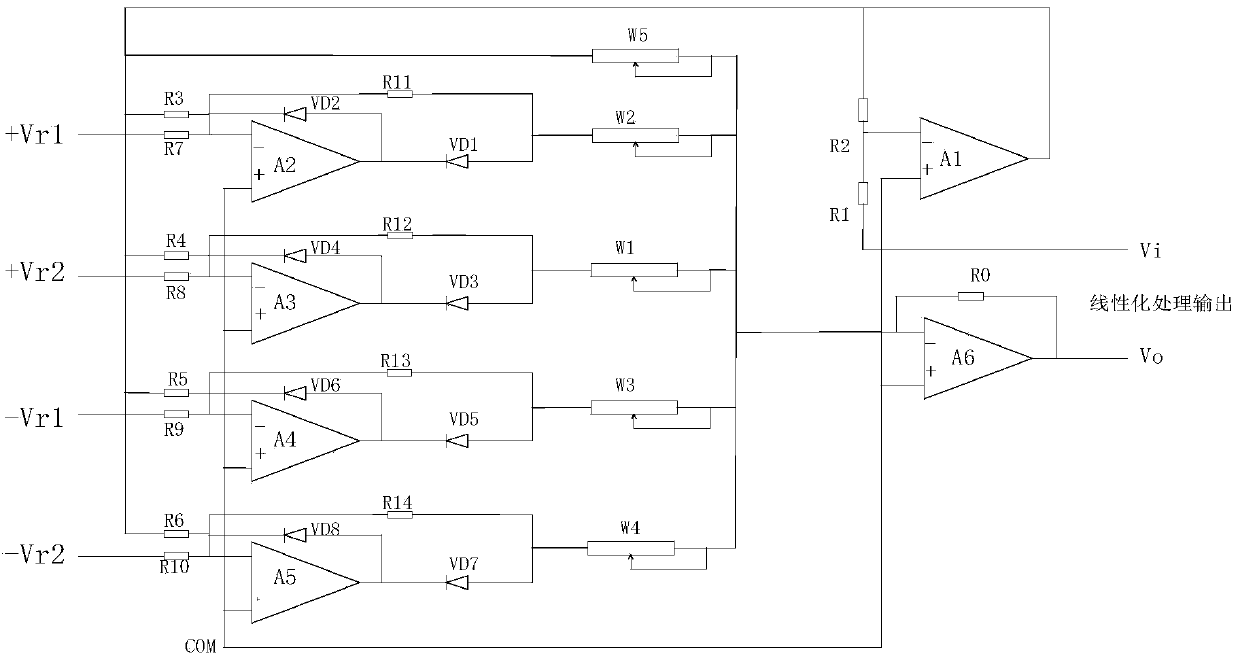

[0025] The blind end of the temperature-sensing tube 1 is a temperature-sensing head that can be placed in the temperature field to be measured to sense the temperature and generate a thermal radiation beam. The photoelectric conversion module 2 includes a light tube 20, a focusing mirror 21 and a beam plate arranged in the light tube 20. 22. The beam limiting plate 23 and the photosensitive plate 24. The digital processing module 3 includes a module box body and a multi-section compensation adjustment submodule 31, a standard signal conversion submodule 32 and a network protocol conversion submodule 33 located in the module box body. Standard signal conversion The sub-module 32 and the network protocol conversion sub-module 33 adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com